Transverse cutting device for extruded polystyrene foam plate production equipment

A technology of extruded polystyrene and cross-cutting device, which is applied in metal processing, dust removal, cleaning methods and utensils, etc. It can solve the problems of smoke flying around, blades are not easy to enter smoothly, and blackened foam boards, etc., to achieve The effect of cutting the end face flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

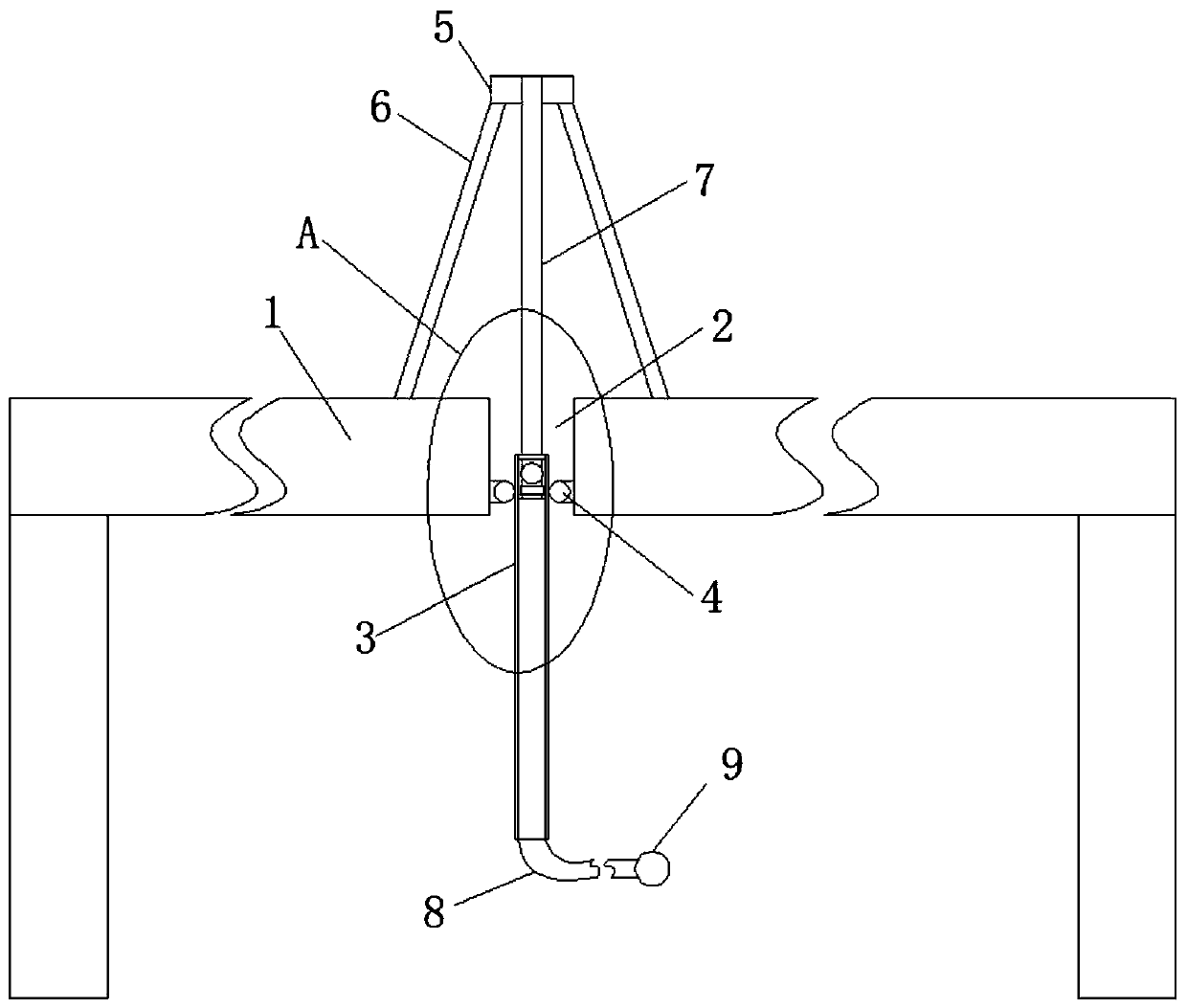

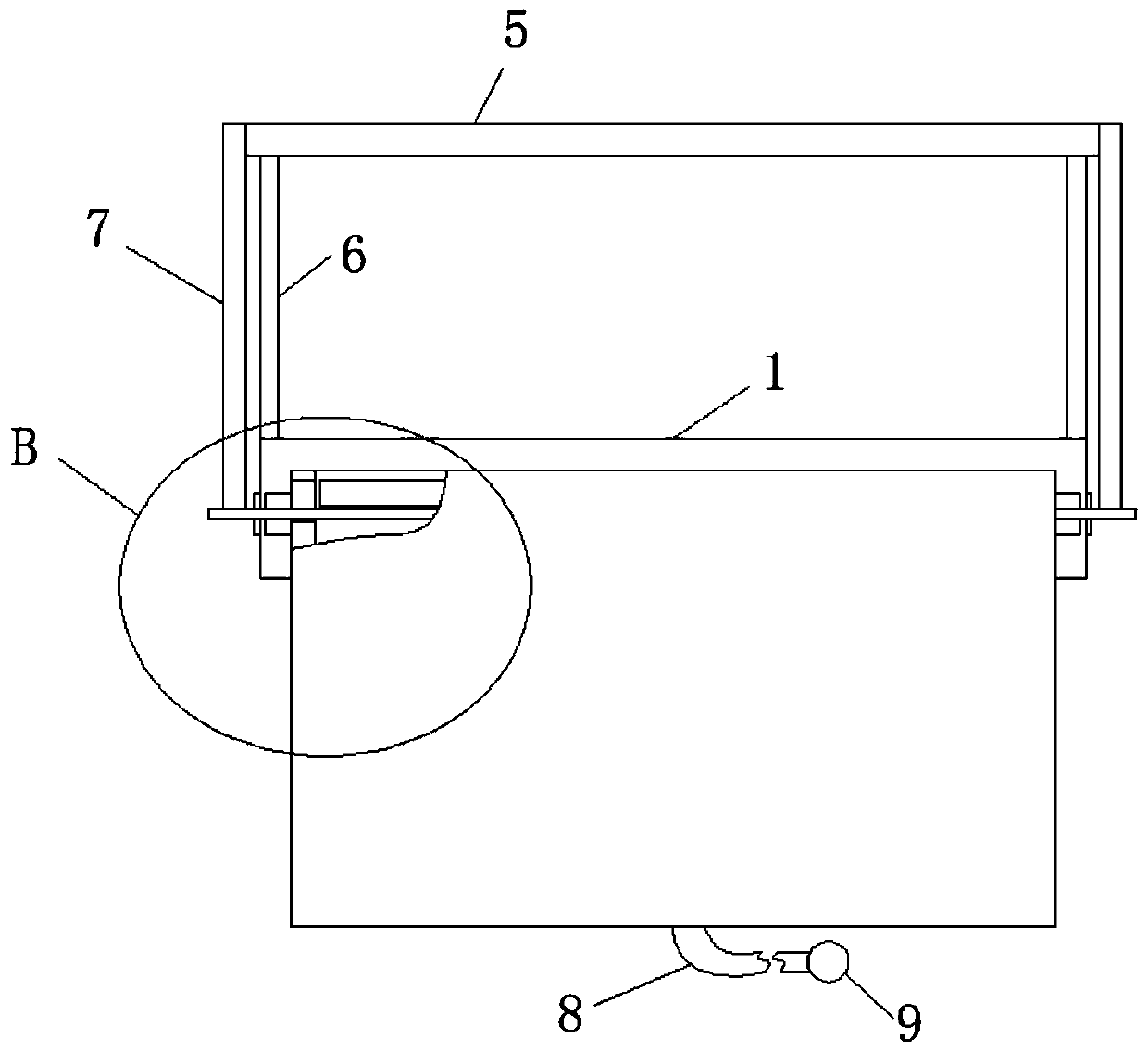

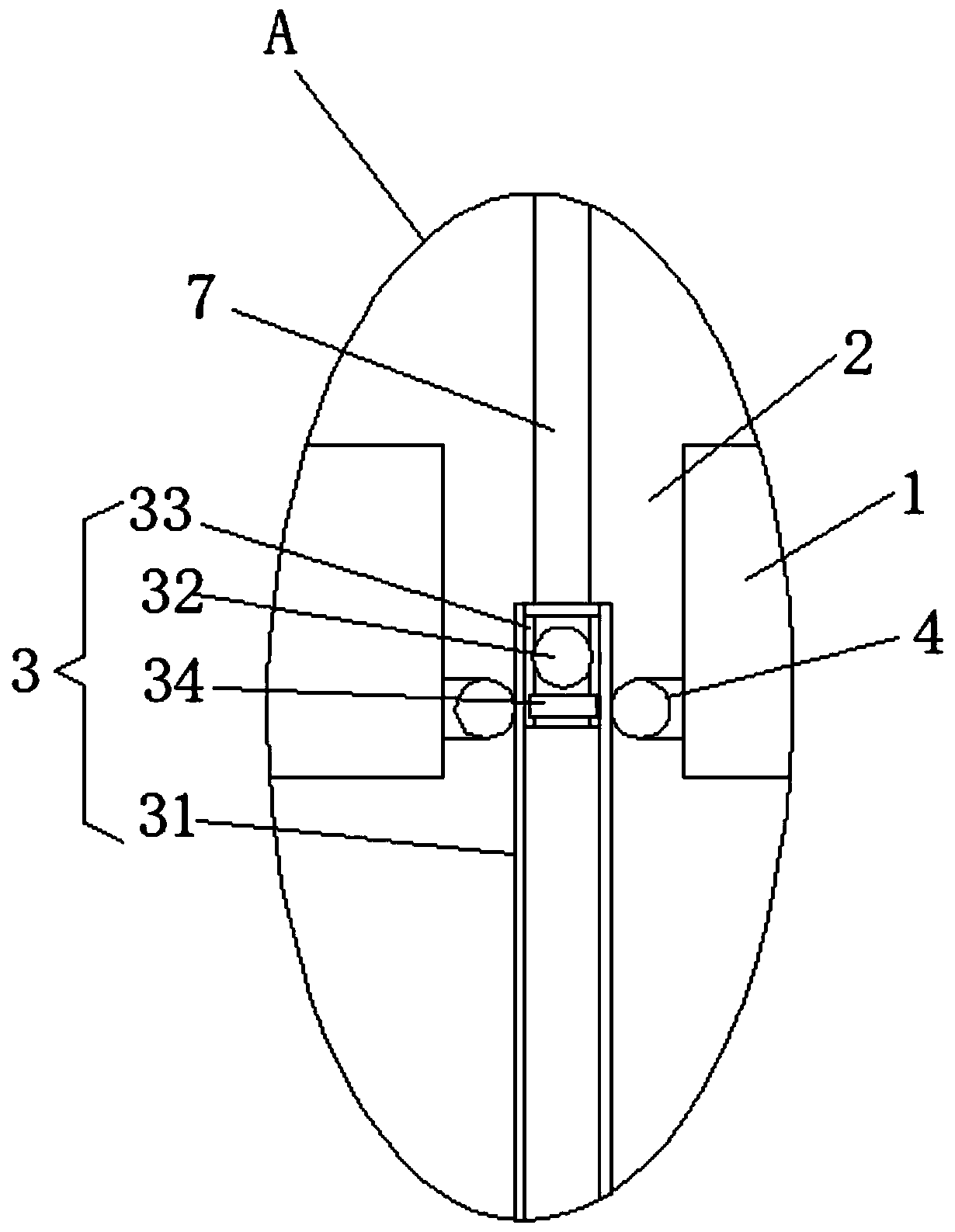

[0027] see Figure 1-4 , the present invention provides a technical solution: a cross-cutting device for producing extruded polystyrene foam board equipment, including a support plate 1, the support plate 1 is horizontally fixed on the frame, and the support plate 1 A fracture 2 is opened on the top, and a cutting knife 3 is arranged inside the fracture 2. The cutting knife 3 can pass through the fracture 2, and both sides of the interior of the fracture 2 are connected with rotating rollers 4, and the rotating rollers 4 clamp and cut Knife 3, a frame plate 5 is arranged above the fracture 2, and the frame plate 5 spans the supporting plate 1, and both ends of the frame plate 5 are fixedly connected to the supporting plate 1 through support rods 6, and the frame plate A linear drive device 7 is installed on the 5, and the linear drive device 7 drives the cutting knife 3 to move up and down in the vertical direction;

[0028] Described cutter 3 comprises cutter body 31, and de...

Embodiment 2

[0032] see Figure 5-8 , the present invention provides a technical solution: a cross-cutting device for producing extruded polystyrene foam board equipment, including a support plate 1, the support plate 1 is horizontally fixed on the frame, and the support plate 1 A fracture 2 is opened on the top, and a cutting knife 3 is arranged inside the fracture 2. The cutting knife 3 can pass through the fracture 2, and both sides of the interior of the fracture 2 are connected with rotating rollers 4, and the rotating rollers 4 clamp and cut Knife 3, a frame plate 5 is arranged above the fracture 2, and the frame plate 5 spans the supporting plate 1, and both ends of the frame plate 5 are fixedly connected to the supporting plate 1 through support rods 6, and the frame plate A linear drive device 7 is installed on the 5, and the linear drive device 7 drives the cutting knife 3 to move up and down in the vertical direction;

[0033]Described cutter 3 comprises cutter body 31, and des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com