Sliding type winding pipe inner cutting device

A technology of winding tube and inner cutting, applied in the direction of metal processing, etc., can solve the problems of inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

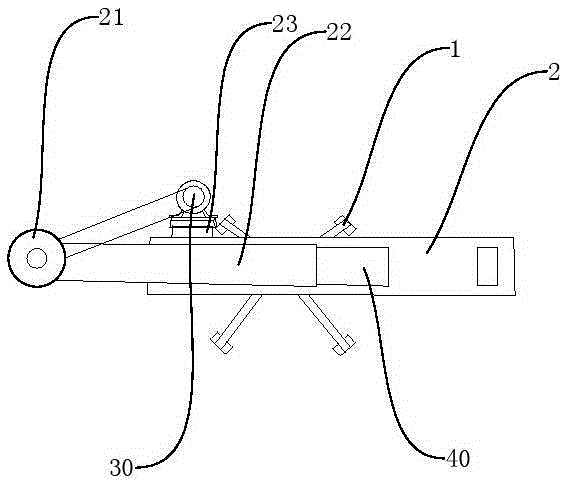

[0014] The reference signs in the drawings of the description include: a support frame 1 , a mounting rod 2 , a circular saw blade 21 , a slider 22 , a mounting plate 23 , a chute 40 , and a motor 30 .

[0015] The embodiment is basically as attached figure 1 Shown: a sliding type winding pipe inner cutting device, including a support frame 1 for connecting the winding machine, a winding machine wall plate with a through hole, a rotating shaft, a mounting rod 2 and a circular saw blade 21; the rotating shaft is hinged on the winding pipe at At the center of the circle when the wallboard of the winding machine is projected into a circle, the support frame 1 is fixed on the wallboard of the winding machine; the rotating shaft is hinged on the supporting frame 1, and the center of the supporting frame 1 is provided with a through hole for the rotating shaft to pass through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com