A kind of oms-2 catalytic material and its preparation method and application

A technology of OMS-2 and catalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of lack of large-scale production and difficulty in obtaining, etc. Achieve the effect of green and environmental protection preparation route, simple operation, and increase pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] One aspect of the embodiments of the present invention provides a method for preparing an OMS-2 catalytic material, which includes:

[0026] Under the air atmosphere, the uniformly mixed reaction system containing manganese carbonate and additives is calcined at 300-500°C for 1-5 hours, and then the calcined solid mixture is acid-treated with potassium salt-containing nitric acid solution to obtain OMS-2 catalyst Material.

[0027] In some more specific embodiments, the preparation method specifically includes: uniformly mixing manganese carbonate and additives, and then performing ball milling treatment to form the uniformly mixed reaction system.

[0028] Further, the speed of the ball milling treatment is 500-700 r / min, and the time is 10-30 min.

[0029] In some more specific embodiments, the acid treatment includes: uniformly mixing the calcined solid mixture with a potassium salt-containing nitric acid solution, and stirring at 50-100°C for 0.1-12 hours to obtain...

Embodiment 1

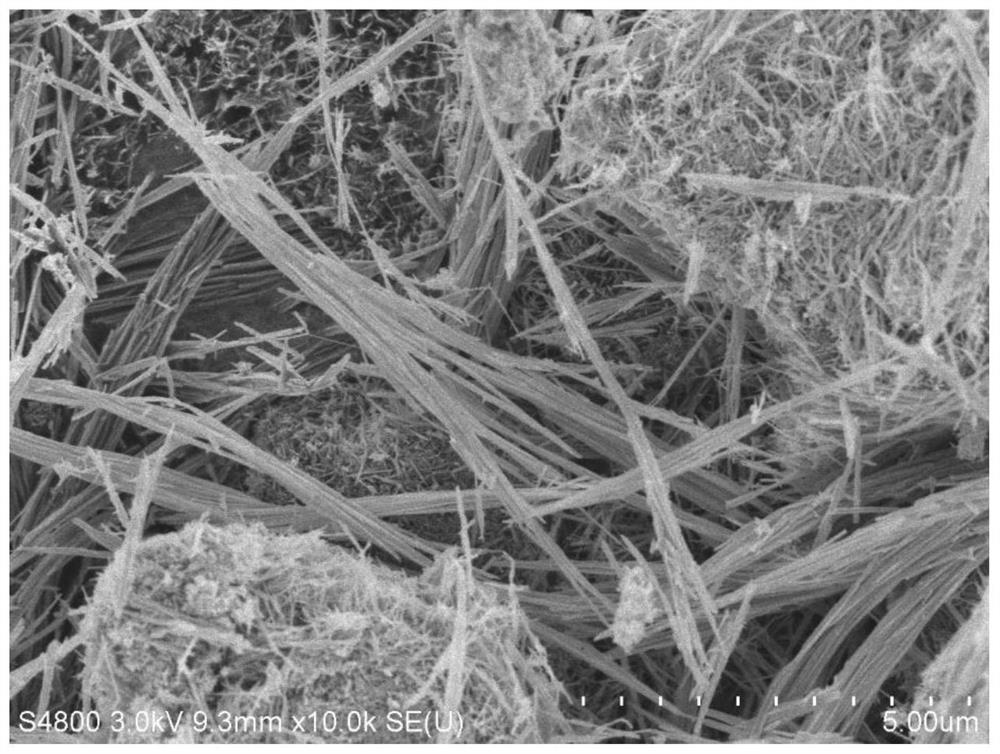

[0054] (1) After mixing 10g of manganese carbonate and 1g of potassium acetate evenly, ball mill for 0.5h, and the solid mixture after ball milling was roasted at 300°C under air for 3h, and then put into 100ml of 0.5mol / L nitric acid aqueous solution in which 1g of potassium carbonate was dissolved , heated and stirred at 90° C. for 2 h, after the reaction was completed, filtered, washed with distilled water, and dried at 90° C. for 5 h to obtain the OMS-2 catalytic material. Material morphology characterization: the SEM spectrum of the OMS-2 catalytic material obtained in this embodiment is as follows figure 1 shown.

[0055] (2) Application of degrading organic pollutants in water

[0056] In the methylene blue dye waste water of 100mg / L, add potassium monomonosulfate, the concentration of potassium monomonosulfate is 500mg / L, then add the OMS-2 catalytic material prepared by the present embodiment in the waste water, this catalytic material is in waste water The concentr...

Embodiment 2

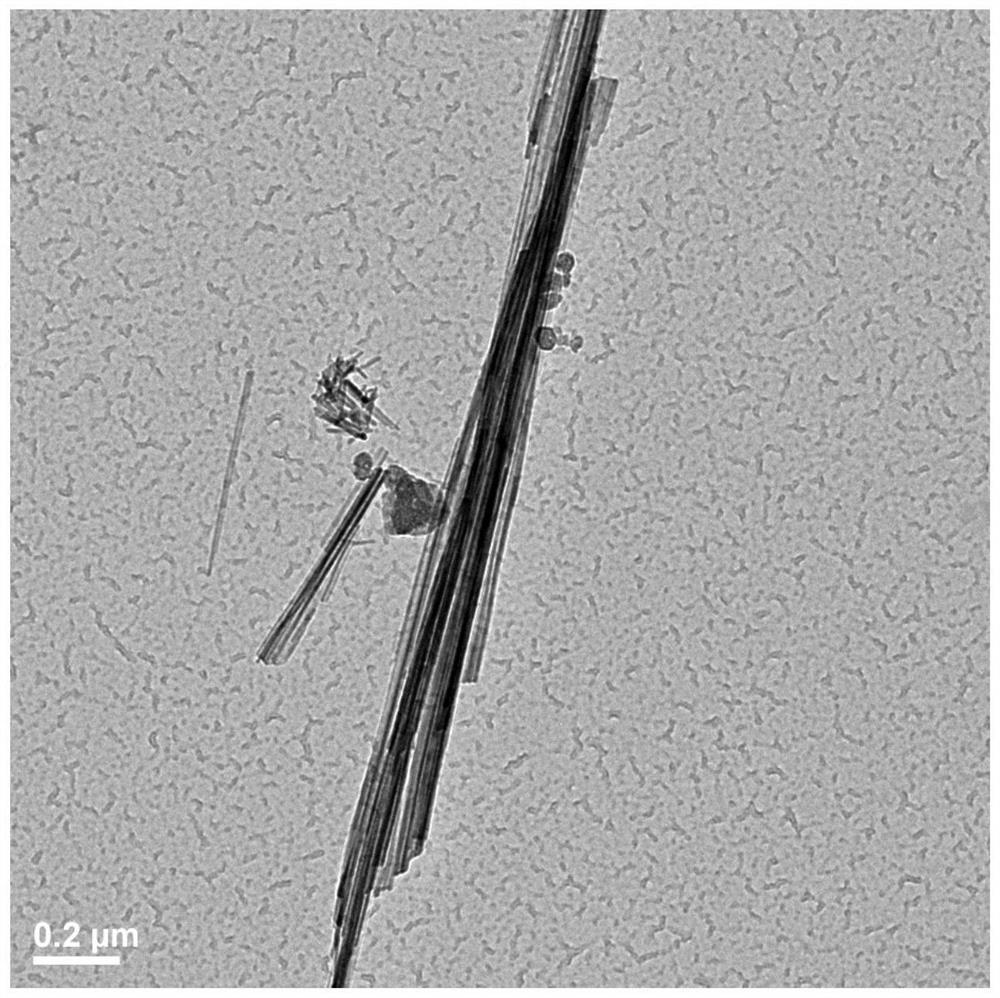

[0060] (1) Mix 10g of manganese carbonate and 10g of potassium oxalate evenly, ball mill for 1 hour, and roast the ball-milled solid mixture at 500°C for 3 hours in air, then put it into 100 mL of 0.1 mol / L nitric acid aqueous solution in which 0.1 g of potassium acetate is dissolved , heated and stirred at 100°C for 12h, after the reaction, filtered, washed with distilled water, and dried at 100°C for 10h to obtain the OMS-2 catalytic material. Material morphology characterization: the TEM spectrum of the OMS-2 catalytic material obtained in this embodiment is as follows figure 2 shown.

[0061] (2) Application of degrading organic pollutants in water

[0062] Add potassium peroxomonosulfate to 50mg / L of acid scarlet G dye waste water, the concentration of potassium peroxomonosulfate is 250mg / L, then add the OMS-2 catalytic material prepared by the present embodiment in the wastewater, the catalytic material The concentration in waste water is 200 mg / L, and after stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com