Reverse osmosis membrane element of water purifier

A technology of reverse osmosis membrane and water purifier, which is applied in reverse osmosis, semi-permeable membrane separation, osmosis/dialysis water/sewage treatment, etc. The effect of utilization, high resource utilization rate, and improved water output speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

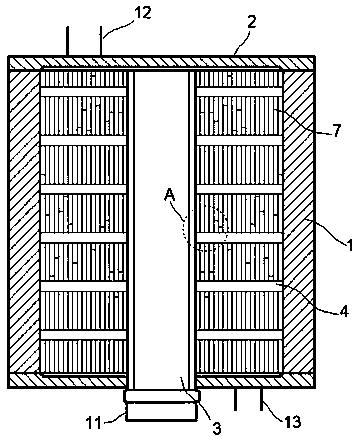

[0014] exist figure 1 , figure 2 In the shown embodiment, the reverse osmosis membrane element of the water purifier includes a housing 1, a sealing cover 2, a central tube 3 and a diaphragm 7, the sealing cover 2 is arranged at both ends of the housing 1, and the central The pipe 3 is arranged at the center line of the housing 1; the central pipe 3 is connected to the water purification pipe 11, and the sealing cover 2 is provided with a water inlet pipe 12 and a water outlet pipe 13;

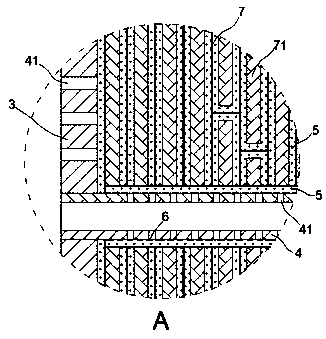

[0015] A puncture tube 4 is connected to the side of the central tube 3, and the puncture tube 4 is uniformly distributed on the tube wall of the central tube 3; one end of the puncture tube 4 communicates with the central tube 3, and the other end is closed. The tube wall of the tube 3 and the puncture tube 4 is provided with a diversion hole 41; the outer wall of the central tube 3 and the puncture tube 4 is wrapped with a reverse osmosis membrane 5; between the puncture tube 4 and the rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com