Device and method for treating tail gas by utilizing carbide slag slurry in acetylene production through indirect circulation method

A technology for tail gas treatment and slag slurry, which is applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of affecting the treatment effect, reducing the waste gas treatment capacity, and the expensive price of sodium hydroxide, etc., and achieves good leaching effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

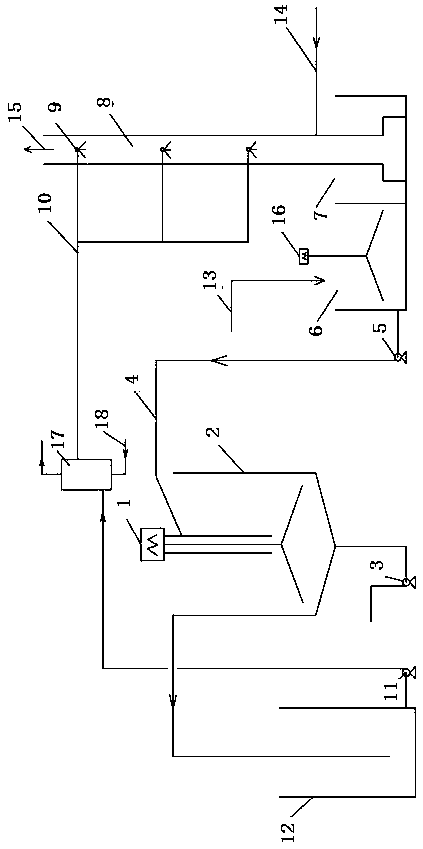

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] see figure 1 , a tail gas treatment device of calcium carbide slag slurry indirect circulation method, based on using the supernatant of calcium carbide slag slurry to neutralize and absorb acidic gas or gas that generates acidic substances when it encounters water, so as to achieve the purpose of tail gas treatment. The principle can be expressed by the following reaction equation :

[0030] Acid gas:

[0031] h + +OH - =H 2 o

[0032] Gases that form acidic substances in contact with water (using silicon tetrachloride as an example):

[0033] SiCL 4 +H 2 0=Si0 2 +HCL

[0034] HCL+Ca(OH) 2 =CaCL 2 +H 2 0

[0035] Based on the above principles, the calcium carbide slag slurry indirect circulation tail gas treatment device provided in this embodiment consists of a leaching tower 8, a rinsing tank 7, a neutralization tank 6, a clari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com