Making method with fishy smell of canned fish lessened

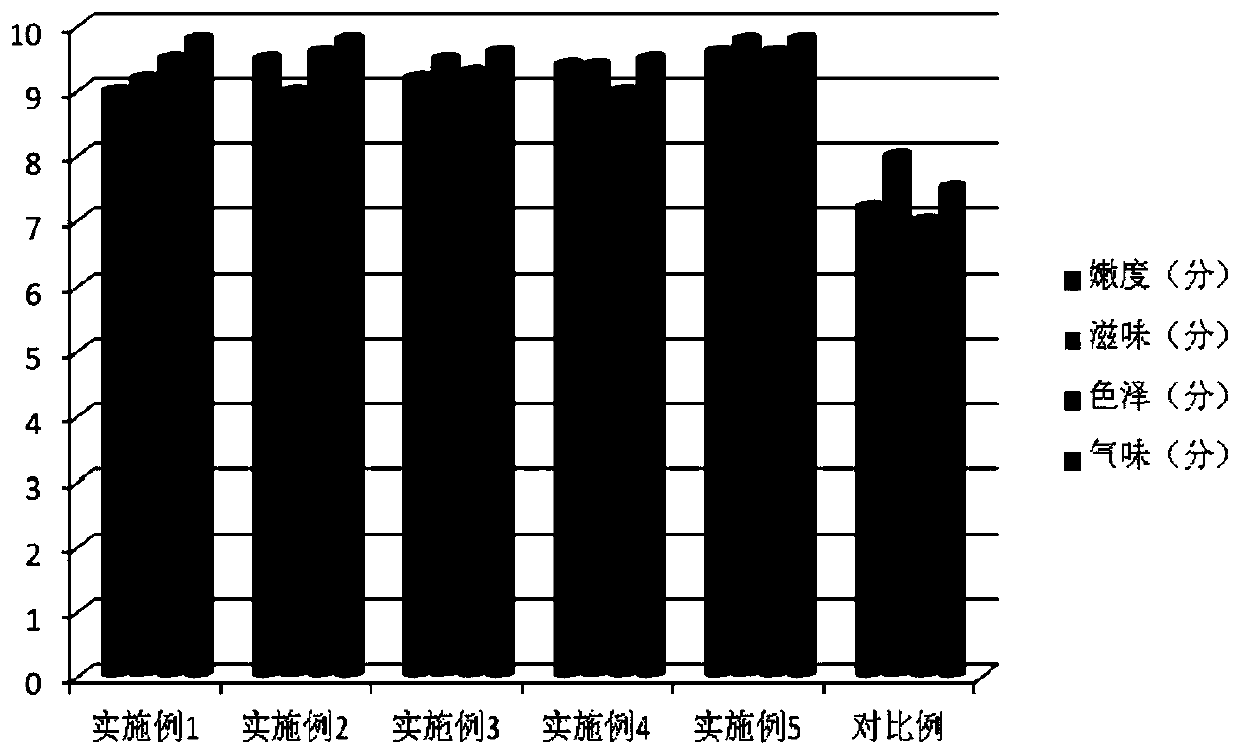

A production method and technology of canned fish, which are applied in the fields of preserving meat/fish with chemicals, food science, etc., can solve the problems of poor taste and appearance integrity, insufficient meat quality, heavy fishy smell, etc., and achieve a simple method for removing fishy smell. , bright color, fresh taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for reducing fishy smell of canned fish

[0027] It includes the steps of cleaning tuna meat, removing fishy smell, drying, ripening the fish meat, seasoning the soup, sterilizing and filling the tuna, wherein the specific method for removing the fishy smell is as follows:

[0028] A1, cut the cleaned tuna into pieces, and then place the pieces in CaCl at a temperature of 88°C 2 Soak in the solution for 3 minutes, then drain to obtain fishy pieces that are initially deodorized; wherein, the fishy pieces and CaCl 2 The mass ratio of the solution is 1:2.0; the size of the fish cuts is: length 40mm, width 25mm, thickness 10mm; CaCl 2 CaCl in solution 2 The mass fraction is 2.5%; using hot CaCl 2 Preliminary deodorization by soaking in the solution can remove some impurities and fishy smell and improve the umami taste of canned fish;

[0029] A2, soak the initially deodorized fish pieces obtained in step A1 in a yeast solution with a temperature of ...

Embodiment 2

[0032] A preparation method for reducing fishy smell of canned fish

[0033] It includes the steps of cleaning sea bass fish meat, removing fishy smell, drying, ripening fish meat, seasoning soup, sterilizing and canning, wherein the specific method of removing fishy smell is as follows:

[0034] A1, cut the washed sea bass flesh into pieces, and then place the fish pieces in CaCl at a temperature of 100°C 2 Soak in the solution for 5 minutes, then drain to obtain fishy pieces that are initially deodorized; wherein, the fishy pieces and CaCl 2 The mass ratio of the solution is 1:2.5; the size of the fish cuts is: length 45mm, width 35mm, thickness 15mm; CaCl 2 CaCl in solution 2 The mass fraction of 3.5%;

[0035]A2, soak the initially deodorized fish pieces obtained in step A1 in a yeast solution at a temperature of 42°C for 90 minutes, spray the color-fixing solution on the fish pieces soaked in the yeast solution, and then soak them in a temperature of -36°C. Freeze-dry...

Embodiment 3

[0038] A preparation method for reducing fishy smell of canned fish

[0039] It includes the steps of cleaning tuna meat, removing fishy smell, drying, ripening the fish meat, seasoning the soup, sterilizing and filling the tuna, wherein the specific method for removing the fishy smell is as follows:

[0040] A1, cut the cleaned tuna into pieces, and then place the pieces in CaCl at a temperature of 90°C 2 Soak in the solution for 5 minutes, then drain to obtain fishy pieces that are initially deodorized; wherein, the fishy pieces and CaCl 2 The mass ratio of the solution is 1:2.1; the size of the fish cuts is: length 41mm, width 27mm, thickness 11mm; CaCl 2 CaCl in solution 2 The mass fraction of 2.7%;

[0041] A2, soak the initially deodorized fish pieces obtained in step A1 in a yeast solution at a temperature of 39°C for 70 minutes, spray the color-fixing solution on the fish pieces soaked in the yeast solution, and then soak them in a temperature of -34°C. Freeze-dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com