Gas pressure limiting valve with annular gap seat for control and discharge of gaseous media

A gas pressure and gaseous medium technology, applied in the field of pressure limiting valves, can solve problems such as low medium flow, damage, and time-consuming pressure drop, and achieve the effects of pressure pulsation, wear reduction, and wear reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

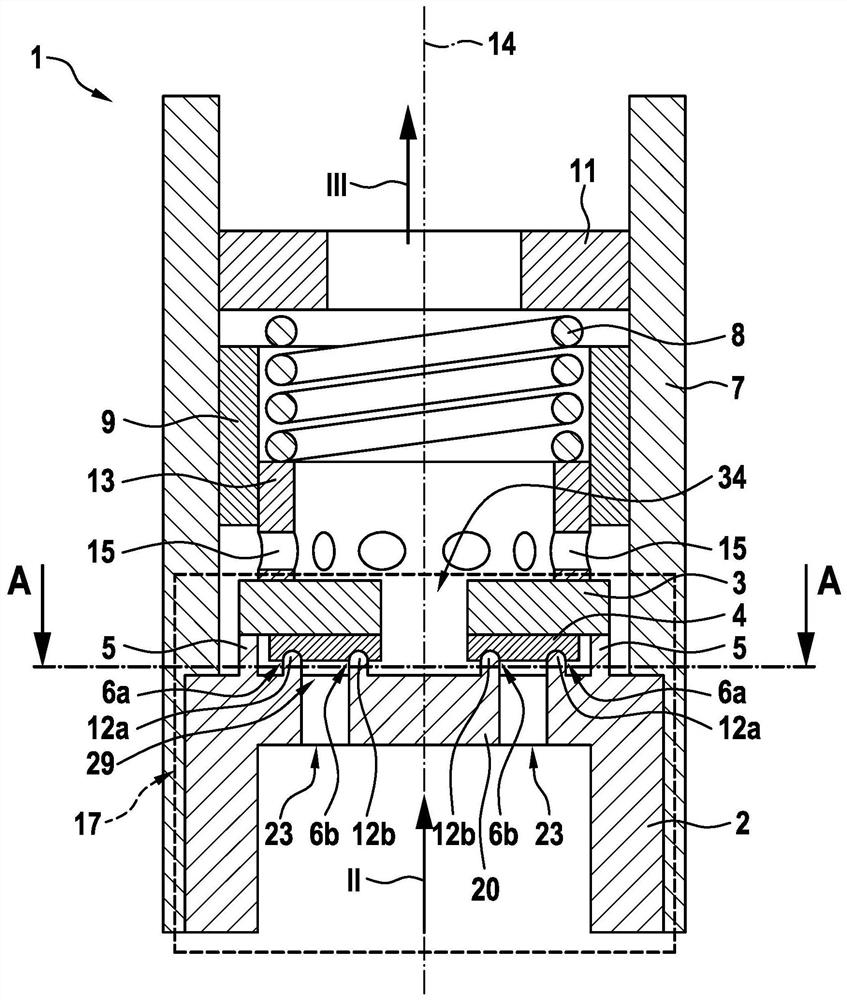

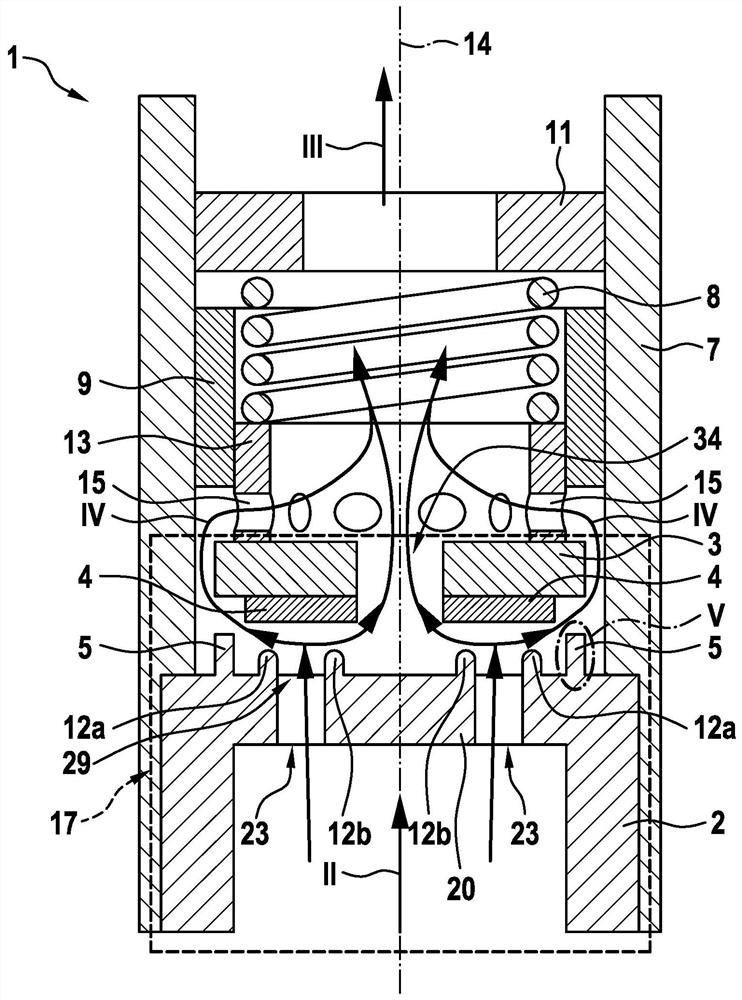

[0030] Below, according to a preferred embodiment refer to figure 1 and figure 2 A schematic sectional view of a pressure limiting valve 1 , in particular a gaseous pressure limiting valve 1 , for controlling and discharging media, in particular gaseous media, is shown. The pressure limiting valve 1 shown here serves to control a medium, in particular gaseous hydrogen, which is supplied to a fuel cell 30 in the vehicle, and to discharge a medium starting from a defined pressure range.

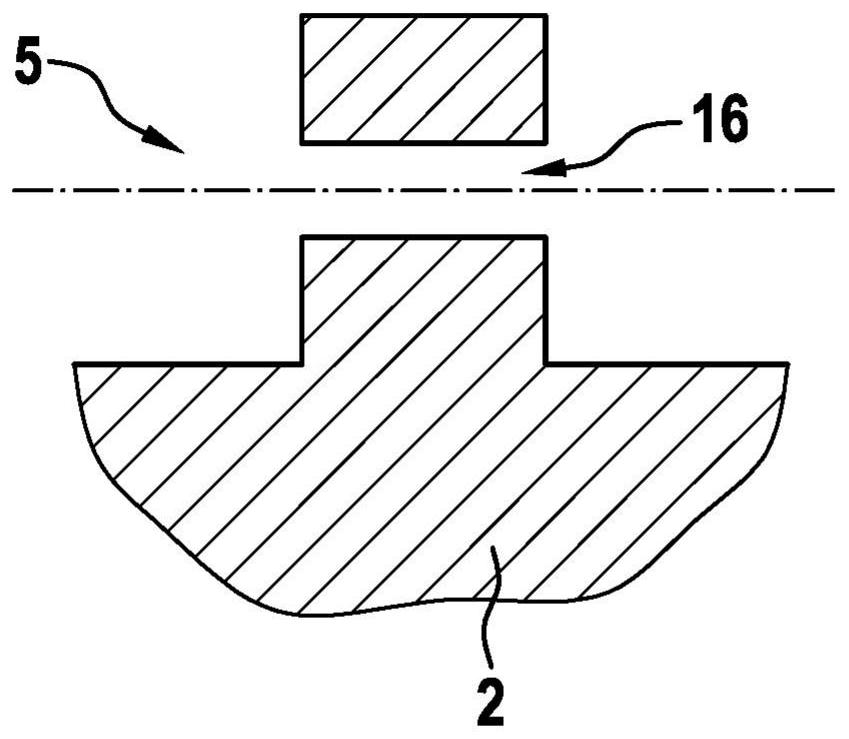

[0031] as by figure 1 It can be seen that the gas pressure limiting valve 1 comprises a housing 7, a valve element mounting assembly 17, a sleeve-shaped element 13 on which the closing spring 8 is supported, in particular a guide element 9 for guiding the closing spring 8 and a closing spring support 11. The valve element mounting 17 also has a sealing seat plate 2 and a valve element 3 , wherein the valve element 3 abuts against the sleeve-shaped element 13 in the direction of the longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com