Low-iron-loss variable flux permanent magnet memory motor robustness design method for electric automobile

A technology for memory motors and electric vehicles, applied in the direction of electric vehicles, motors, electric components, etc., can solve problems such as long calculation time, high cost, complex objective function establishment, etc., to achieve reduction of harmonic components, reduction of iron consumption of motors, iron consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

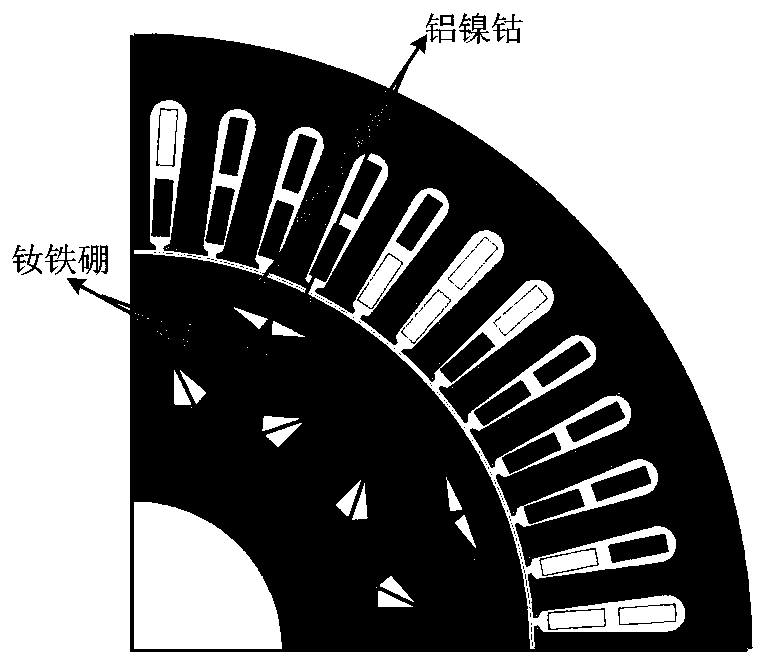

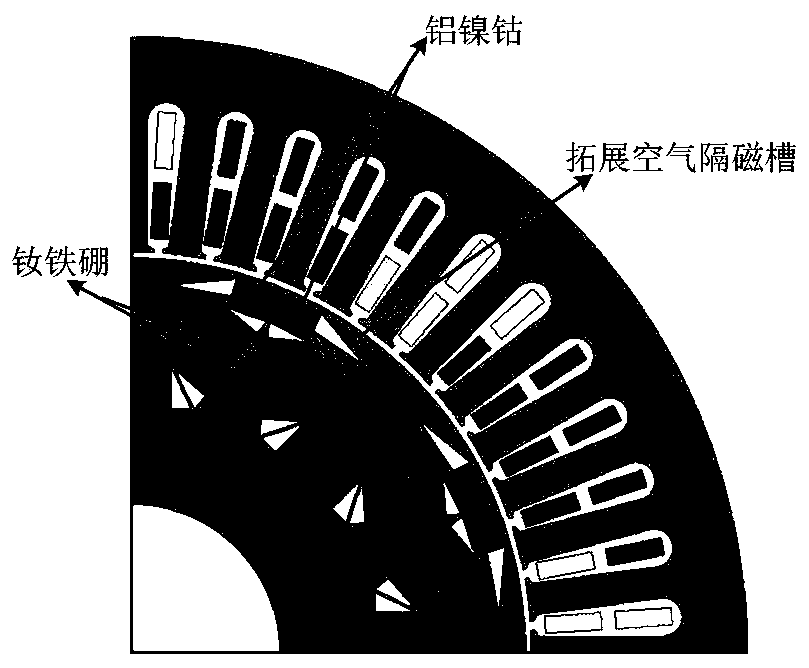

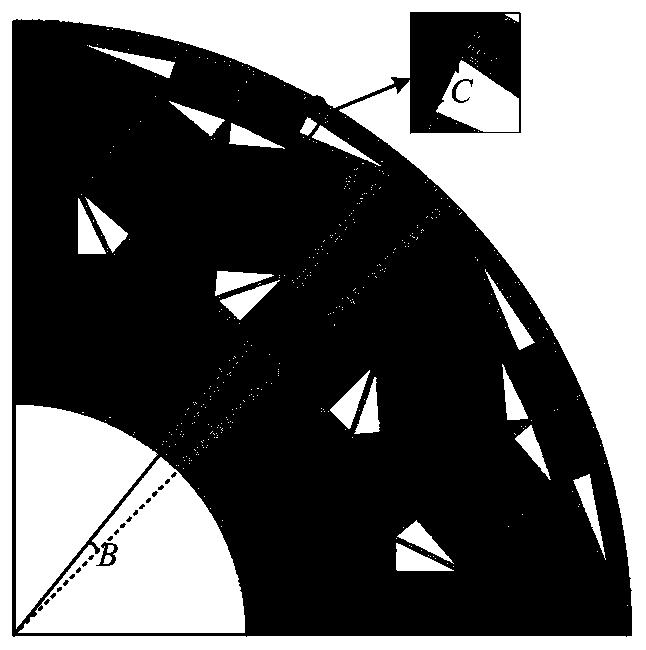

[0024] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Taking a variable flux permanent magnet memory motor for electric vehicles as an example to carry out the structural robustness design of the low iron loss variable flux permanent magnet memory motor, the parameters of the motor are shown in Table 1.

[0025] Table 1 Parameters of inner rotor motor

[0026] parameter symbol value unit Rated speed n N

3000 r / min Number of pole pairs P 4 -- Number of slots Q 48 -- Rotor air gap radius R ra

64 mm air gap length δ 1 mm Radius at stator yoke R sy

100 mm core length l 140 mm NdFeB permanent magnet residual flux density B rNdFeB

1.125 T Coercive force of NdFeB permanent magnet H cNdFeB

886 kA / m Alnico permanent magnet residual magnetic density B rAlNiCo

0.6 T AlNiCo permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com