Macro preparation method of titanium-oxygen cluster compound

A kind of cluster compound, titanium oxide technology, applied in the field of macro-scale preparation of titanium oxide cluster compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

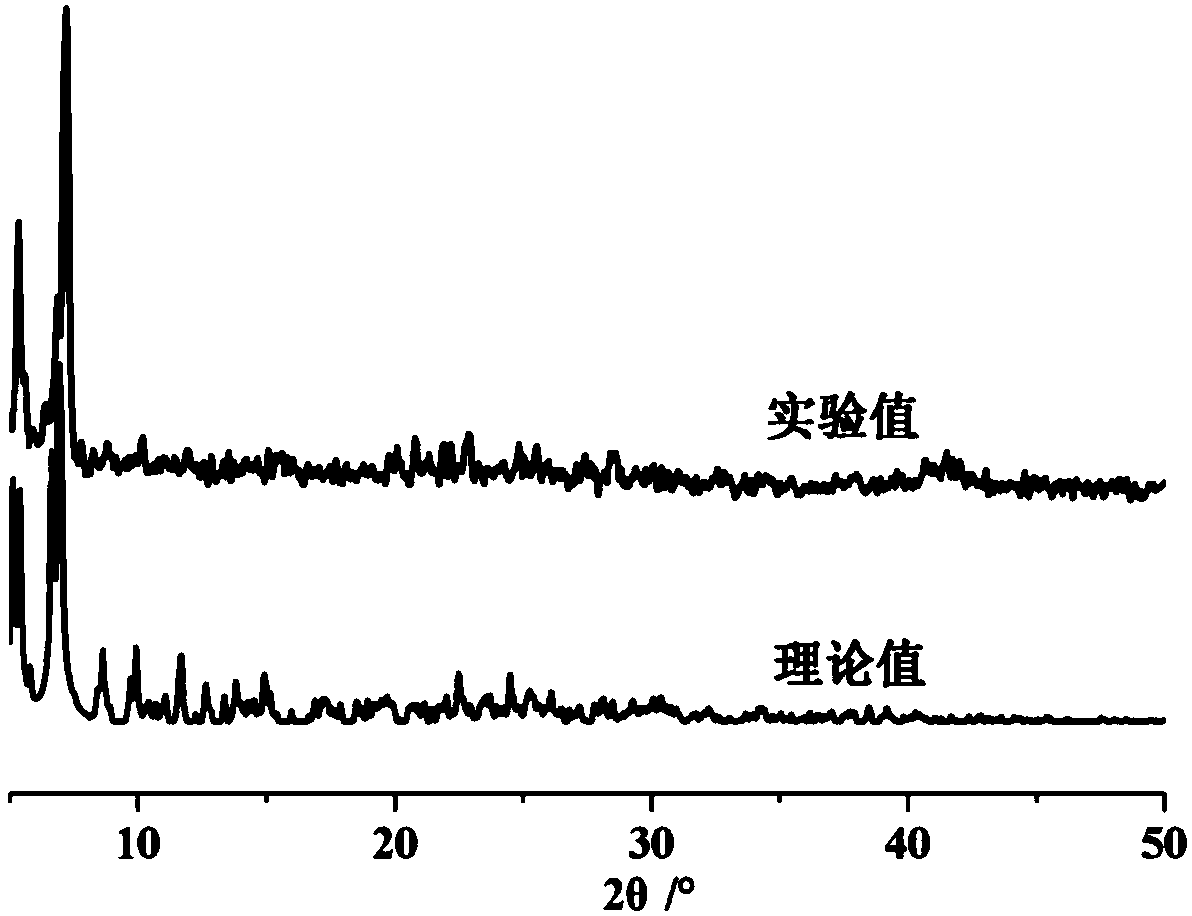

Embodiment 1

[0067] Heating and stirring: Titanium isopropoxide (3.0mmol), formic acid (4.0mmol), and propionic acid (73.6mmol) were placed in a 50ml round bottom flask, mixed uniformly at room temperature, refluxed and stirred at 100°C for 8 hours, and taken out , naturally cooled to room temperature, separated the solid phase and rinsed with propionic acid to obtain the target product in the form of colorless strip crystals.

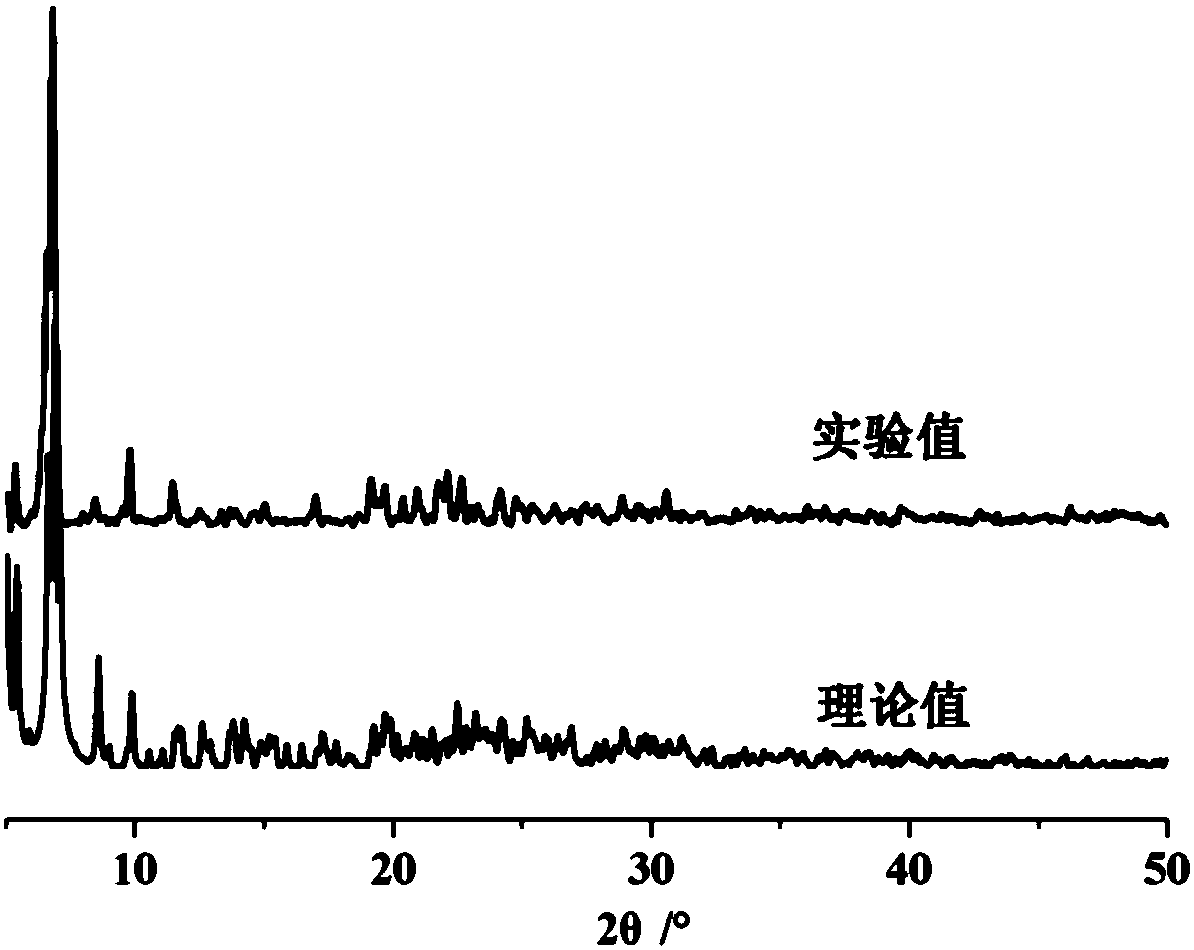

Embodiment 2

[0069] Heating and stirring: Titanium isopropoxide (3.0mmol), formic acid (4.0mmol), propionic acid (60mmol) and octanoic acid (14mmol) were placed in a 50ml round bottom flask, mixed evenly at room temperature, and refluxed and stirred at a temperature of 80°C After 12 hours, it was taken out, naturally cooled to room temperature, the solid phase was separated and washed with propionic acid to obtain the target product in the form of colorless strip crystals.

Embodiment 3

[0071] Heating and stirring: Titanium isopropoxide (3.0mmol), formic acid (26.5mmol), propionic acid (52.0mmol), butyric acid (17.0mmol) were placed in a 50ml round bottom flask, mixed uniformly at room temperature, Reflux and stir for 8 hours, take it out, naturally cool to room temperature, separate the solid phase and wash it with propionic acid to obtain the target product in the colorless strip-like crystal state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com