Ship-sinking-preventing expansion device

A technology of expansion device and ship plate, which is applied in the direction of ship safety, transportation and packaging, ships, etc., can solve the problems of increasing the weight of the hull, unfavorable use, and difficulty in continuing to sail the hull, so as to achieve the effect of ensuring the safety of navigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

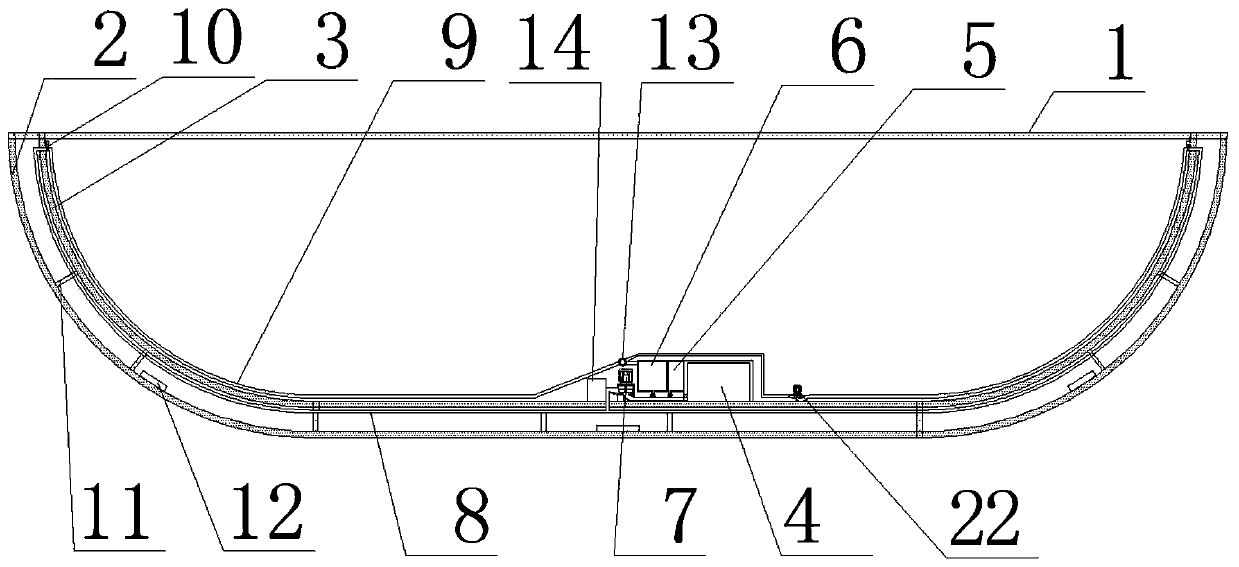

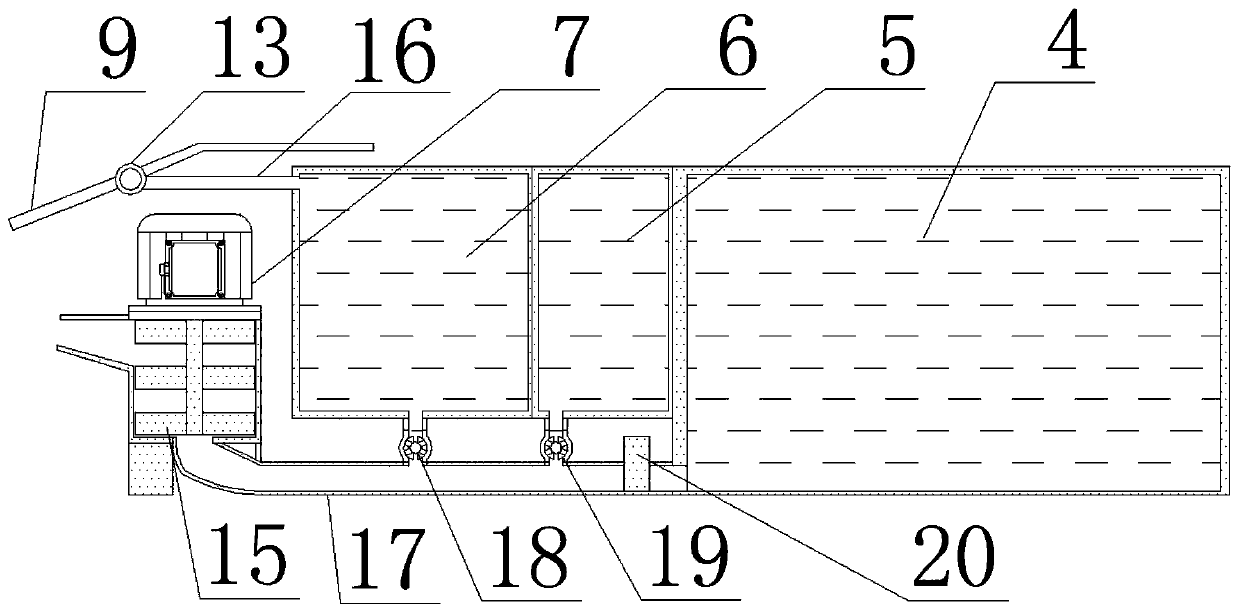

[0030] As a preferred embodiment of the present invention, the impeller 15 is installed inside the high-pressure water pump 7, and the impeller 15 is a multi-layer impeller.

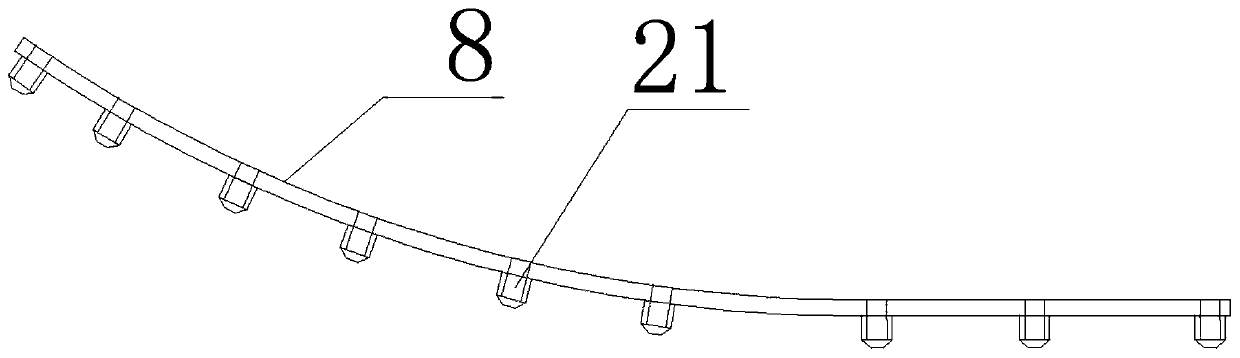

[0031] As a preferred embodiment of the present invention, the nozzle pipe 8 is welded to the bottom of the inner ship plate 3, and one end of the nozzle pipe 8 passes through the bottom of the inner ship plate 3 and is welded on one side of the high-pressure water pump 7, The electric nozzles 21 are evenly distributed on the inner ship deck 3, and the two ends of the nozzle pipe 8 respectively pass through both sides of the inner ship deck 3 and communicate with the return pipe 9.

[0032] As a preferred embodiment of the present invention, one end of the strut 11 is welded on the top of the outer ship plate 2, the top of the strut 11 is welded to the bottom of the inner ship plate 3, and the struts 11 are evenly distributed on the outer ship plate. plate 2.

[0033] As a preferred embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com