Device and method for punching, surface testing and processing of fpc raw materials

A surface inspection and raw material technology, applied in sorting, metal processing, etc., can solve the problems of inability to simultaneously detect and process defects, low precision, and difficulty in defect detection, and reduce the requirements for operating proficiency and punching accuracy High, solve the effect of edge warping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

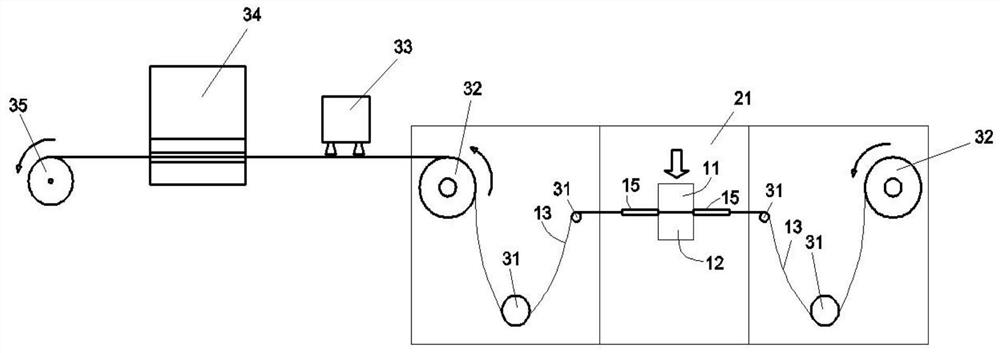

[0029] The device used for punching, surface testing and processing of FPC raw materials as shown in the figure includes an FPC raw material punching unit and an FPC surface testing and processing unit connected in sequence by a conveyor belt;

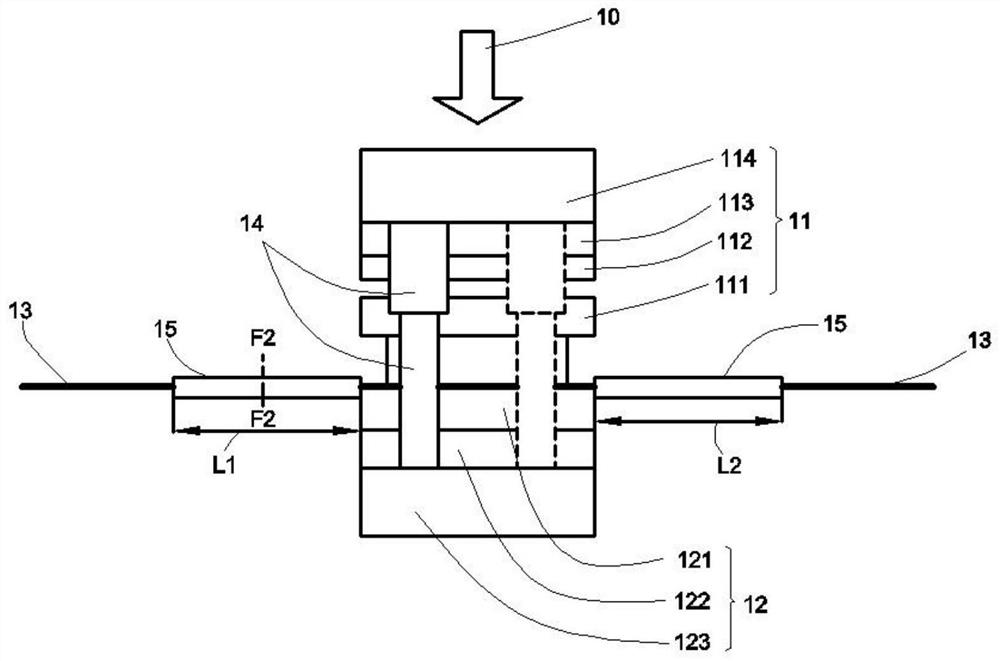

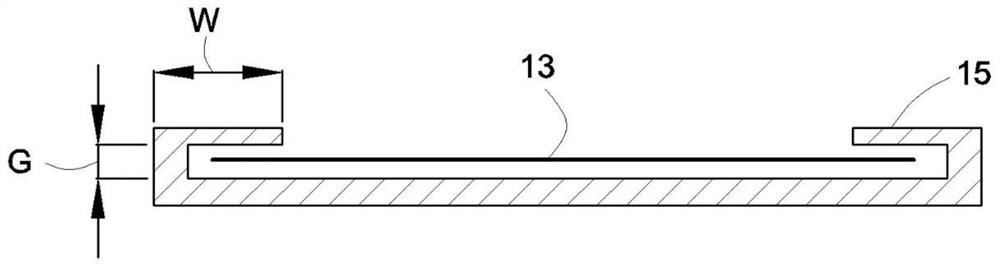

[0030] The FPC raw material punching unit includes a loading device and a punching area; the loading device is composed of 2 powered rollers 32 and 4 rollers 31, and the 2 powered rollers 32 and 4 rollers 31 are not arranged on the same straight line In order to make the FPC raw material 13 unfold without wrinkling; through the cooperation between 2 driven rollers 32, 4 rollers 31 and 2 guide rails 15, the cut FPC raw material 13 is transported to the punching area; punching Zone 21 includes pressure mechanism 10, puncher, upper mold 11, lower mold 12 and two guide rails 15; upper mold 11 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com