A high-efficiency pulverizer for potassium chlorate agglomerated raw materials

A technology of potassium chlorate and pulverizer, which is applied in the direction of grain processing, etc. It can solve the problems of unsatisfactory use requirements, uneven quality of chemical materials, redundant structure, etc., and achieve the effect of promoting crushing efficiency, improving efficiency and quality, and promoting crushing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

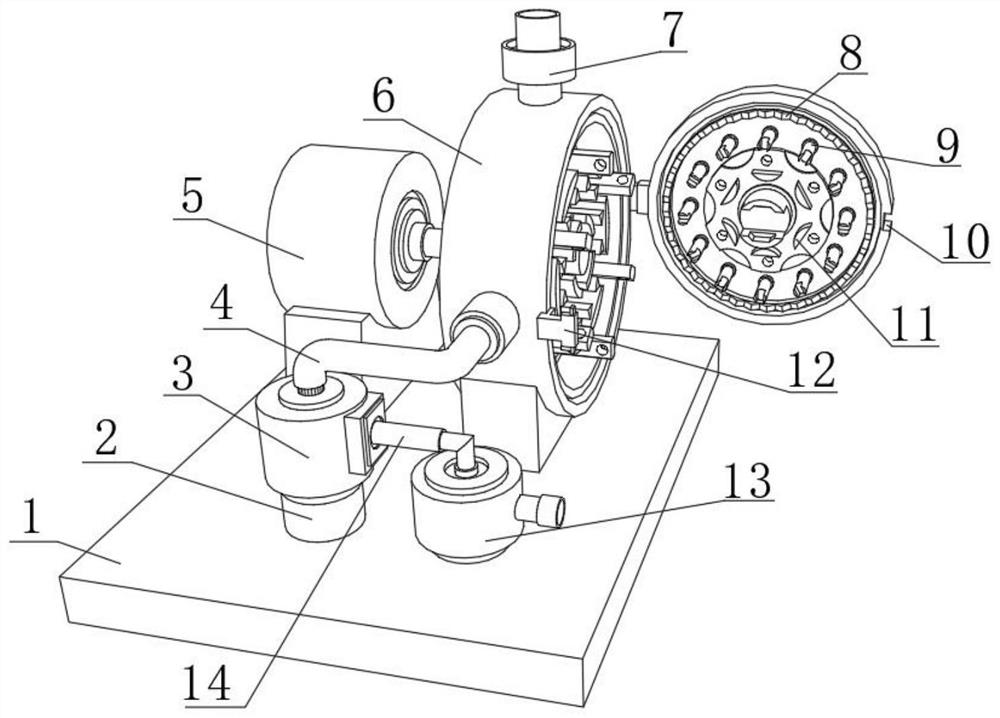

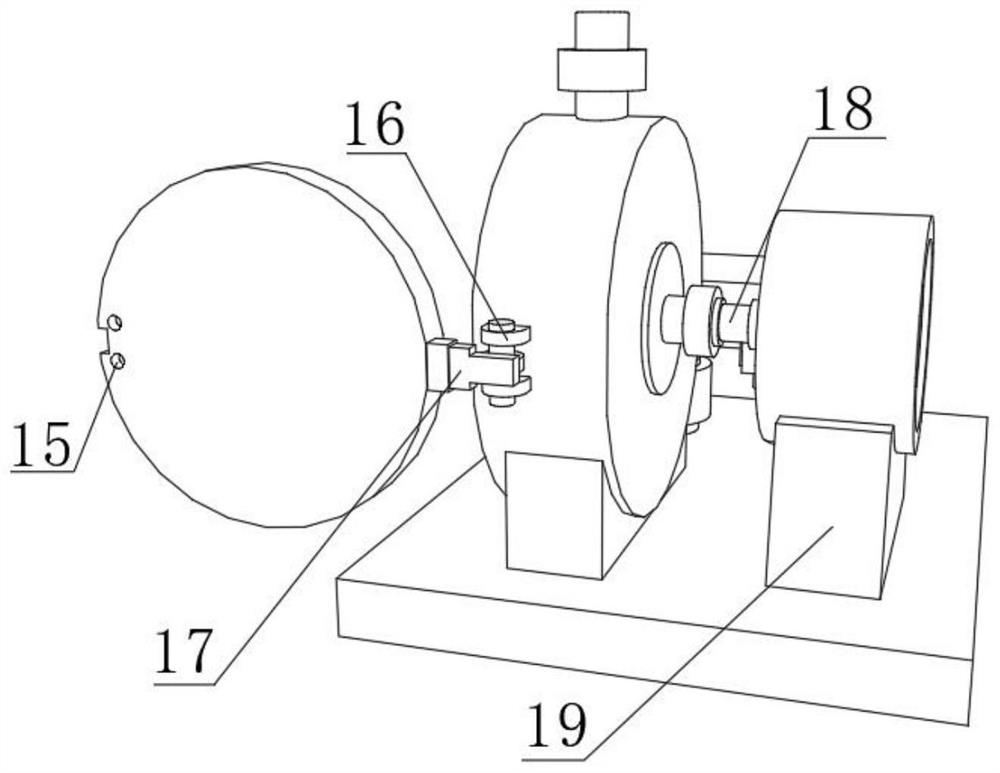

[0030] A kind of high-efficiency pulverizer of potassium chlorate agglomeration raw material, such as figure 1 and figure 2 As shown, the base 1 is included, and the outer wall of the top side of the base 1 is fixed with two bases 19 by bolts, and the outer walls of the top of the two bases 19 are respectively fixed with a second motor 5 and a chassis 6 by bolts. The output shaft of the motor 5 is connected with a rotating shaft 18 through a shaft coupling, and one end of the rotating shaft 18 is fixed with a connecting shaft 23 by a screw thread, the outer wall of the connecting shaft 23 is sleeved with a turntable, and the outer wall of one side of the turntable is provided with a first crushing unit, so The outer wall of the top of the cabinet 6 is fixed with a feed pipe 7 by threads, and the outer wall of the cabinet 6 is welded with a mounting seat, and the outer wall of the cabinet 6 is welded with a card seat 12, and the top and bottom of the card seat 12 are welded wi...

Embodiment 2

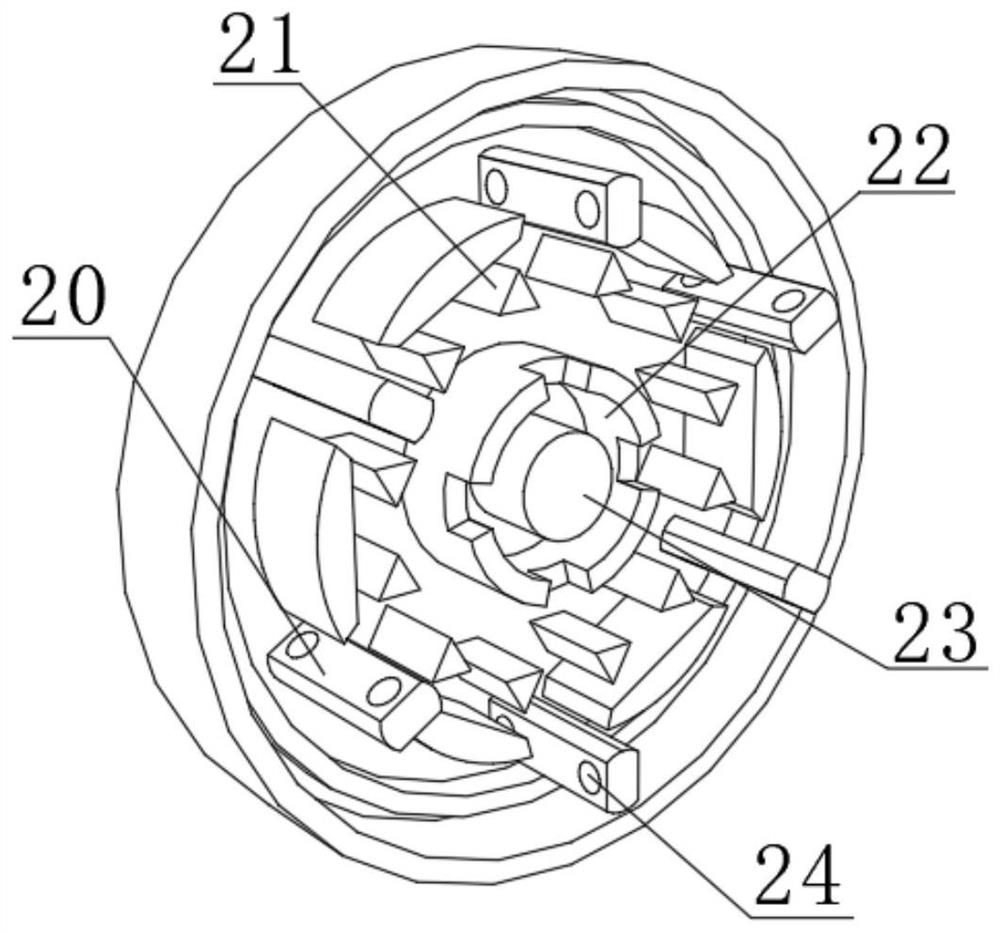

[0035] A kind of high-efficiency pulverizer of potassium chlorate agglomeration raw material, such as Figure 4 As shown, in order to meet the needs of actual production; this embodiment makes the following improvements on the basis of embodiment 1: the second pulverizer unit includes a dispersion disc 25, sawtooth 26, material guide groove 27, fixed shaft 28 and installation shaft cover 29, and the circumferential inner wall of the crushing tube 3 is welded with a fixed ring, the top circumferential inner wall of the fixed ring is welded with several sawtooth 26, the output shaft of the first motor 2 is connected with a fixed shaft 28 through a coupling, and the top end of the fixed shaft 28 is sleeved Connected with dispersing disc 25, the bottom circumference outer wall of fixed shaft 28 is sleeved with installation shaft sleeve 29, and the circumference outer wall of installation shaft sleeve 29 top is welded with several sawtooth 26, and installation shaft sleeve 29 is wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com