Energy-saving novel oilless self-lubricating piston type air compressor, and using method

An air compressor, self-lubricating technology, used in piston pumps, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems of high oil consumption and maintenance costs, pollution of system components, and hydrocarbons, etc. The effect of long life, simple maintenance process and stable gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

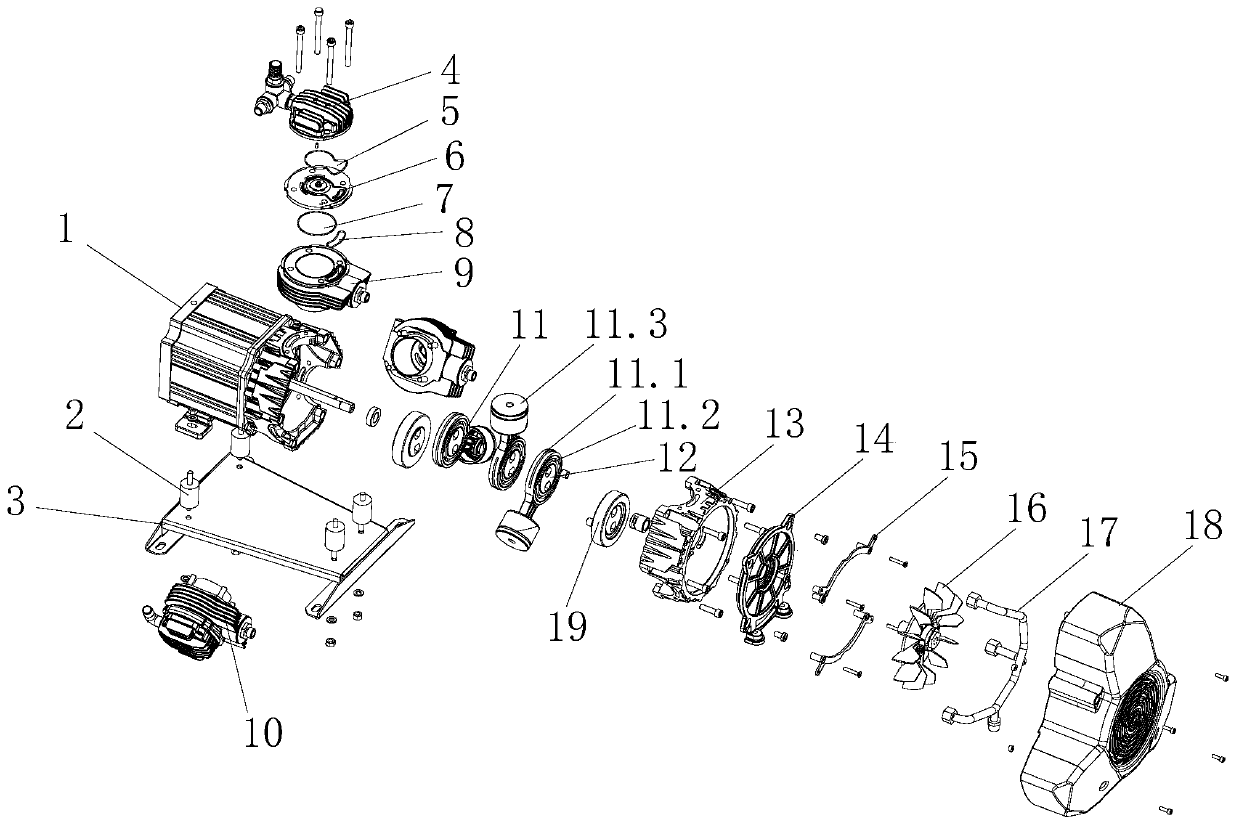

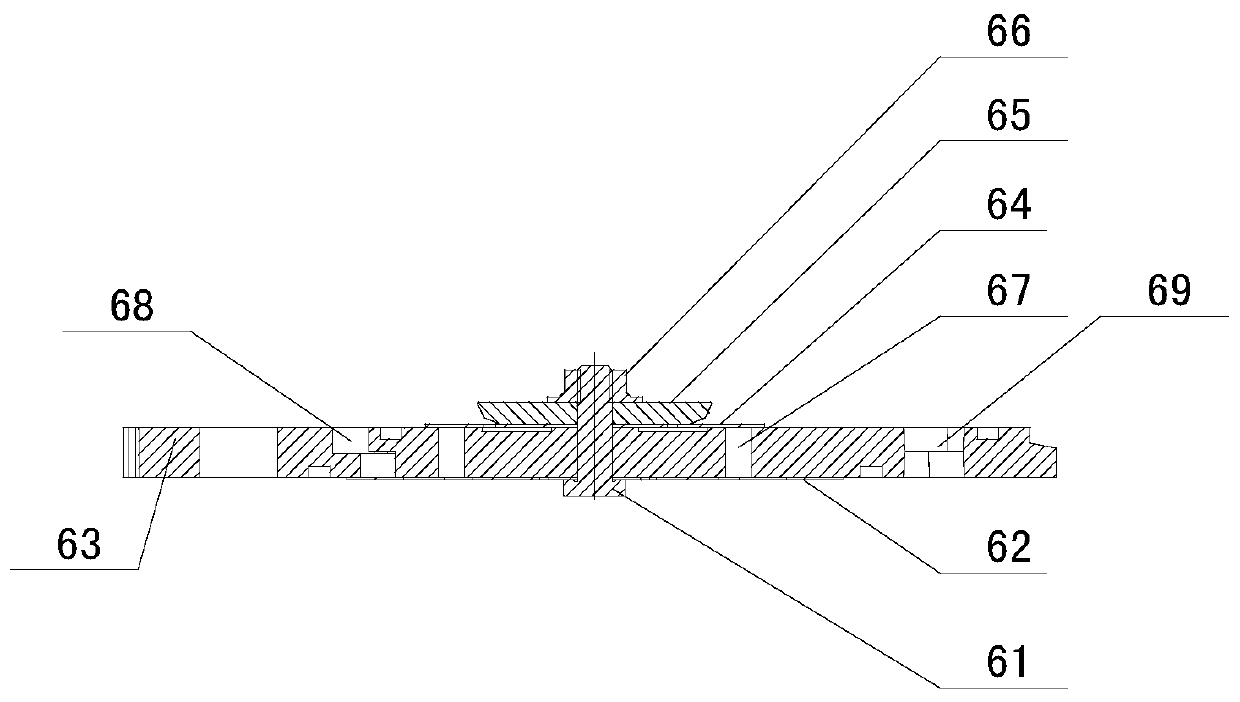

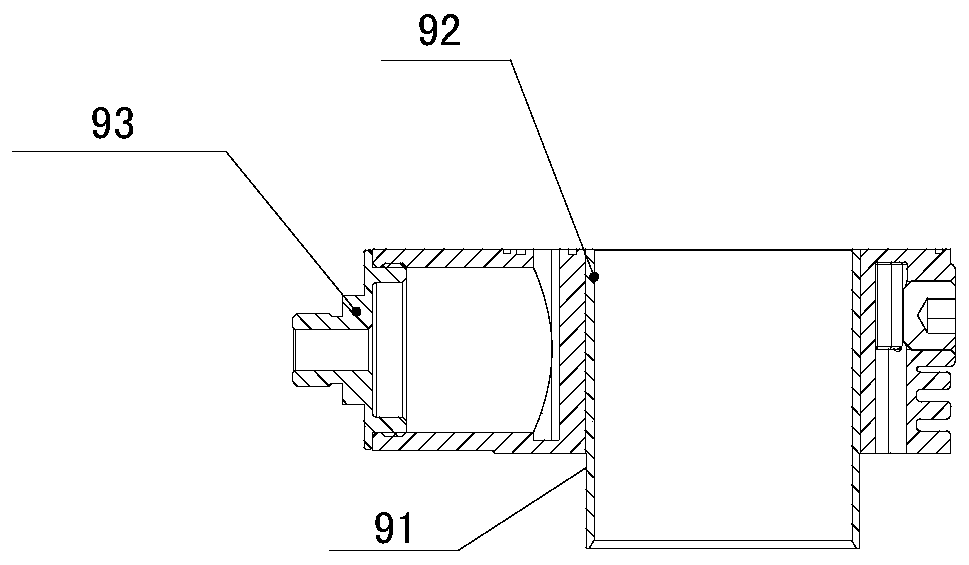

[0054] Embodiment 1, energy-saving novel oil-free self-lubricating piston air compressor, such as Figure 1-3 Shown, comprise motor 1 and crankcase 13.

[0055] The crankcase 13 is fixedly connected on the shaft of the motor 1 by bolts, the three piston assemblies 11 are sleeved on the shaft of the motor 1 through the flat wire holes of the three round sliders 12, the front cover 14 is fixed on the front part of the crankcase 13, and The assembly inside the crankcase 13 is fixed by the shaft of the fan 16, and the cylinder assembly 10 is fixed on the crankcase 13 by bolts. The axial displacements of the three cylinder assemblies 10 are evenly distributed at an included angle of 120 degrees in the circumferential direction.

[0056] The edge (non-circle center) position of circular slider 12 is provided with the flat thread hole that the shaft of power supply motor 1 passes, namely the axis of motor 1 passes the edge of circular slider 12, can drive circular slider 12 to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com