A processing method for aviation ph13-8mo parts

A processing method and parts technology, applied in the processing field of aviation PH13-8Mo parts, can solve the problems of large tool wear, difficult machining, low processing efficiency, etc., reduce tool wear, reduce heating time and energy consumption, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

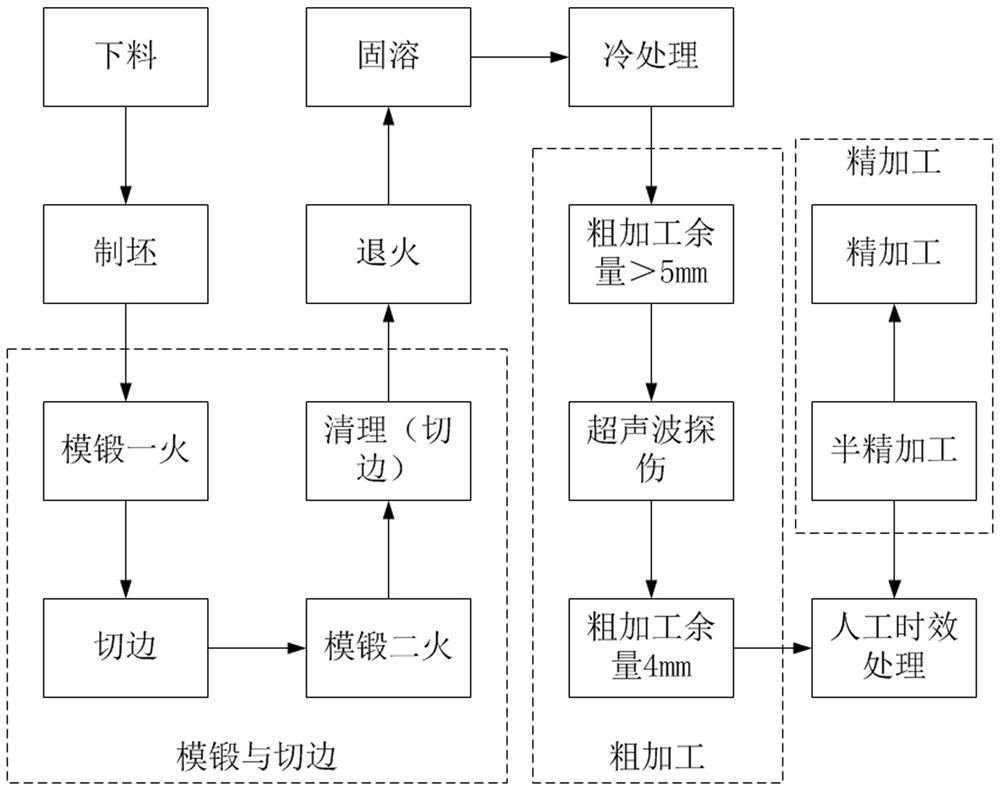

[0032] The specific process of this embodiment, such as figure 1 shown, including the following steps:

[0033] (1) The PH13-8Mo bar is blanked, blanked, and after at least one die forging and edge trimming, a forging of a certain shape is formed, and annealed at 600~760°C to eliminate the residual stress in the forging process;

[0034] (2) Solid solution treatment of forgings;

[0035] (3) Then cold-treat the forging;

[0036] (4) After the cold treatment is completed, the forgings are roughly machined to initially form blank parts;

[0037] (5) Perform artificial aging treatment on the finished blank parts;

[0038] (6) Finally, finish machining the blank parts to make finished aviation PH13-8Mo parts.

Embodiment 2

[0040] The embodiments of this city are based on the above embodiments, and are further limited in the step (1), the number of die forging is once or twice, and the number of die forging depends on the complexity of the parts, such as figure 1 As shown, during the secondary die forging, it is necessary to trim or clean the forging of the first die forging before the second die forging can be carried out. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0042] The embodiment of this city is based on the above embodiments, and further defines that in the step (2), the solution treatment process of the forging is as follows: heating the forging to 800~1000°C, keeping it warm for 150~1800 minutes, and then heating it Raise the temperature by 5~45°C, keep it warm for 50~90 minutes, and cool to room temperature. Realize the stabilization of the solid solution of the PH13-8Mo material and avoid the precipitation of the precipitated phase. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com