Super-hydrophobic magnetic mixture as well as preparation method and application thereof

A hybrid, super-hydrophobic technology, applied in magnetic coatings, inorganic compound addition, special paper, etc., can solve the problems of weak binding force between CNF and inorganic magnetic particles, the preparation process is not environmentally friendly, and hinders practical application, etc. High hydroxyl activity, reducing or avoiding shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

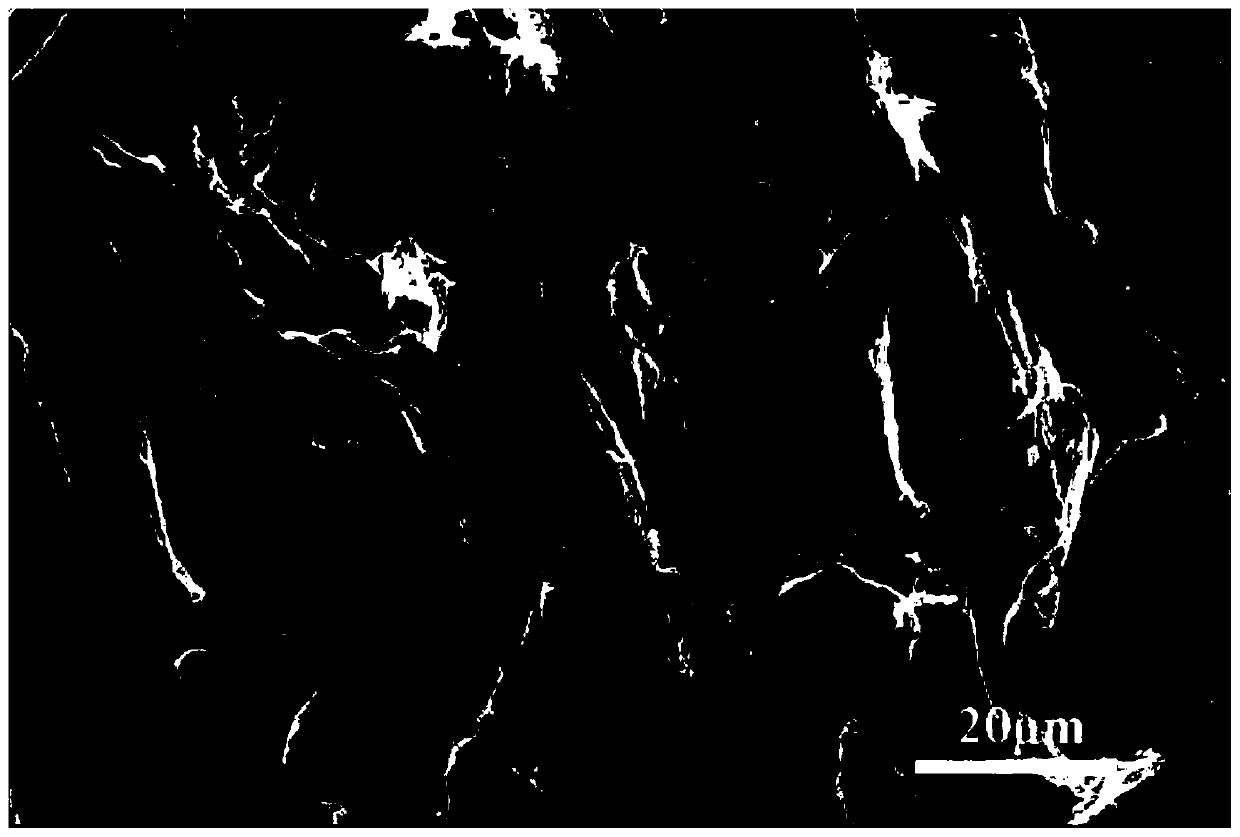

[0038] CNF / Fe 3 o 4 Modification of the mixture

[0039] Use the diameter to be 5-20nm, the nano-cellulose fibril (CNF) that length is 0.5-2 μm is formulated as 0.8wt% water suspension, adds the Fe of 15wt% 3 o 4 (Particle size is 5-20nm) Mix and stir for 30min, adjust the pH value of the mixture to 7. Then add a hydrophobic modifier composed of divinyltriaminopropyltrimethoxysilane (AS) and octyltrimethoxysilane (OTMS) (the volume ratio of OTMS and AS is 1:0.5), and continue to stir for 6 hours , to get CNF / Fe 3 o 4 modified mixture.

[0040] CNF / Fe 3 o 4 Preparation of superhydrophobic magnetic airgel

[0041] The above CNF / Fe 3 o 4 Pour the modified mixture into a mold with a length × width × height of 30 × 30 × 15cm, place it in liquid nitrogen, keep the height of the liquid nitrogen at about one-third of the height of the mold and freeze for 15 minutes, and wait for the CNF / Fe 3 o 4 The modified mixture is completely frozen into ice crystals; then it is moved...

Embodiment 2

[0043] CNF / Fe 3 o 4 Modification of the mixture

[0044] Use CNF with a diameter of 5-20nm and a length of 0.5-2μm to prepare a 0.8wt% aqueous suspension and add 20wt% Fe 3 o 4 (Particle size is 5-20nm) Mix and stir for 30min, adjust the pH value of the mixture to 7. Then add a combined modifier consisting of divinyltriaminopropyltrimethoxysilane (AS) and 1H,1H,2H,2H,-perfluorooctyltriethoxysilane (POTS) (POTS and AS volume The ratio is 1:0.5), continue to stir for 6 hours, you can get CNF / Fe 3 o 4 modified mixture.

[0045] CNF / Fe 3 o 4 Preparation of superhydrophobic magnetic paper

[0046] The above CNF / Fe 3 o 4 Pour the modified mixture into a funnel with a sand core, connect the suction filter, and filter to form; then put it in a blast drying oven at 170°C for 30 minutes to obtain CNF / Fe 3 o 4 Superhydrophobic magnetic paper.

Embodiment 3

[0048] CNF / Fe 3 o 4 Modification of the mixture

[0049] Use CNF with a diameter of 5-20nm and a length of 0.5-2μm to prepare a 0.8wt% aqueous suspension and add 25wt% Fe 3 o 4 (Particle size is 5-20nm) Mix and stir for 30min, adjust the pH value of the mixture to 7. Then add a combined modifier consisting of divinyltriaminopropyltrimethoxysilane (AS) and 1H,1H,2H,2H-perfluorooctyltrichlorosilane (PFCTS) (the volume ratio of PFCTS and AS is 1 :0.5), continue to stir for 6 hours to get CNF / Fe 3 o 4 modified mixture.

[0050] CNF / Fe 3 o 4 Preparation of superhydrophobic magnetic coating

[0051] Using wood block as substrate, the above CNF / Fe 3 o 4 Put the modified mixture into a spray gun, spray it directly on the surface of the wood block, and put it in a blast drying oven at 170°C for 30 minutes to obtain CNF / Fe 3 o 4 Superhydrophobic magnetic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com