Laser cutting device for noninvasive OLED glass substrate

A glass substrate and laser cutting technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of difficult adjustment of cutting pressure and depth, high price of high-power laser equipment, and difficulty in multi-photon cutting control. Achieve the effect of good cutting effect, high yield rate and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

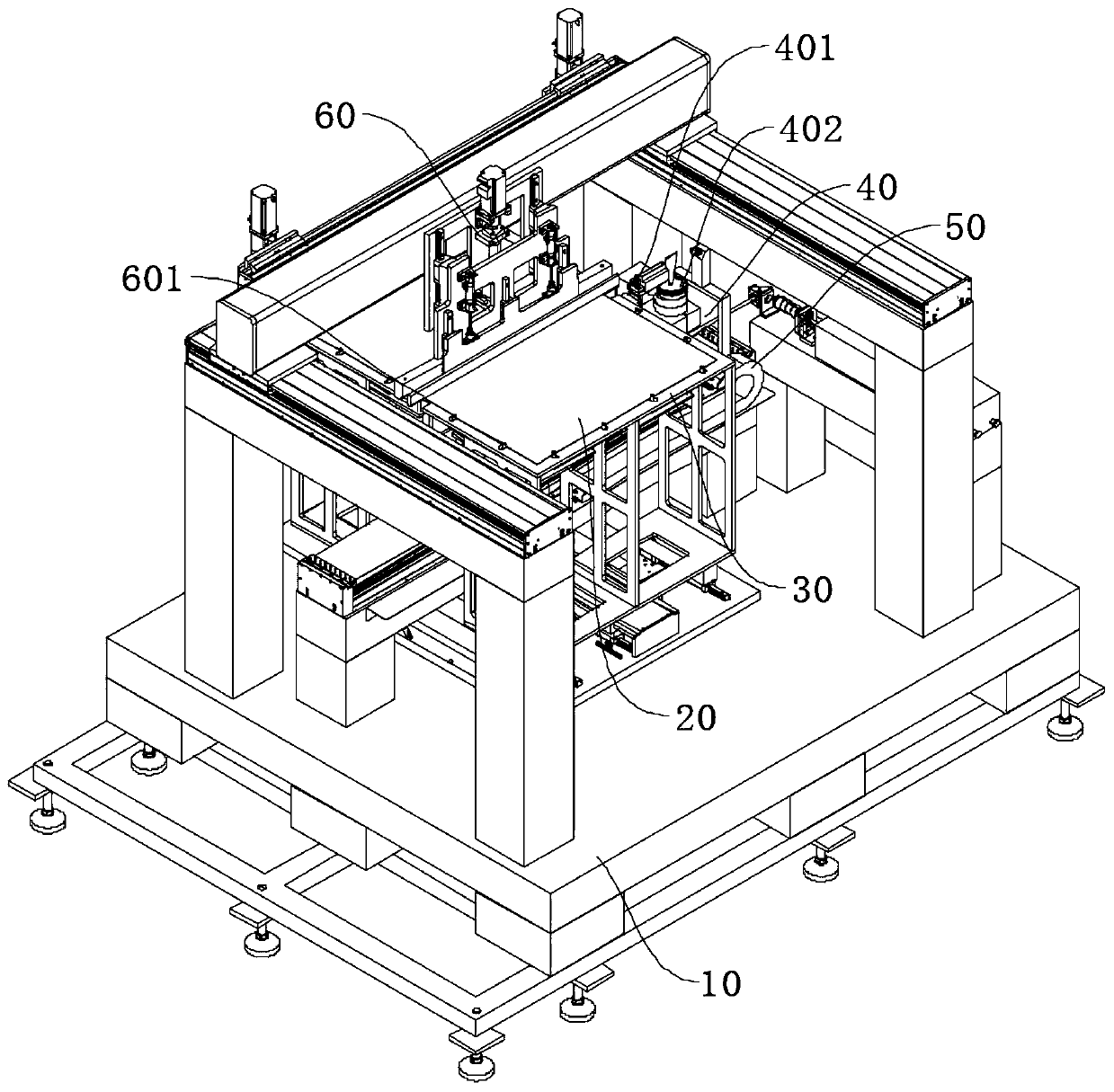

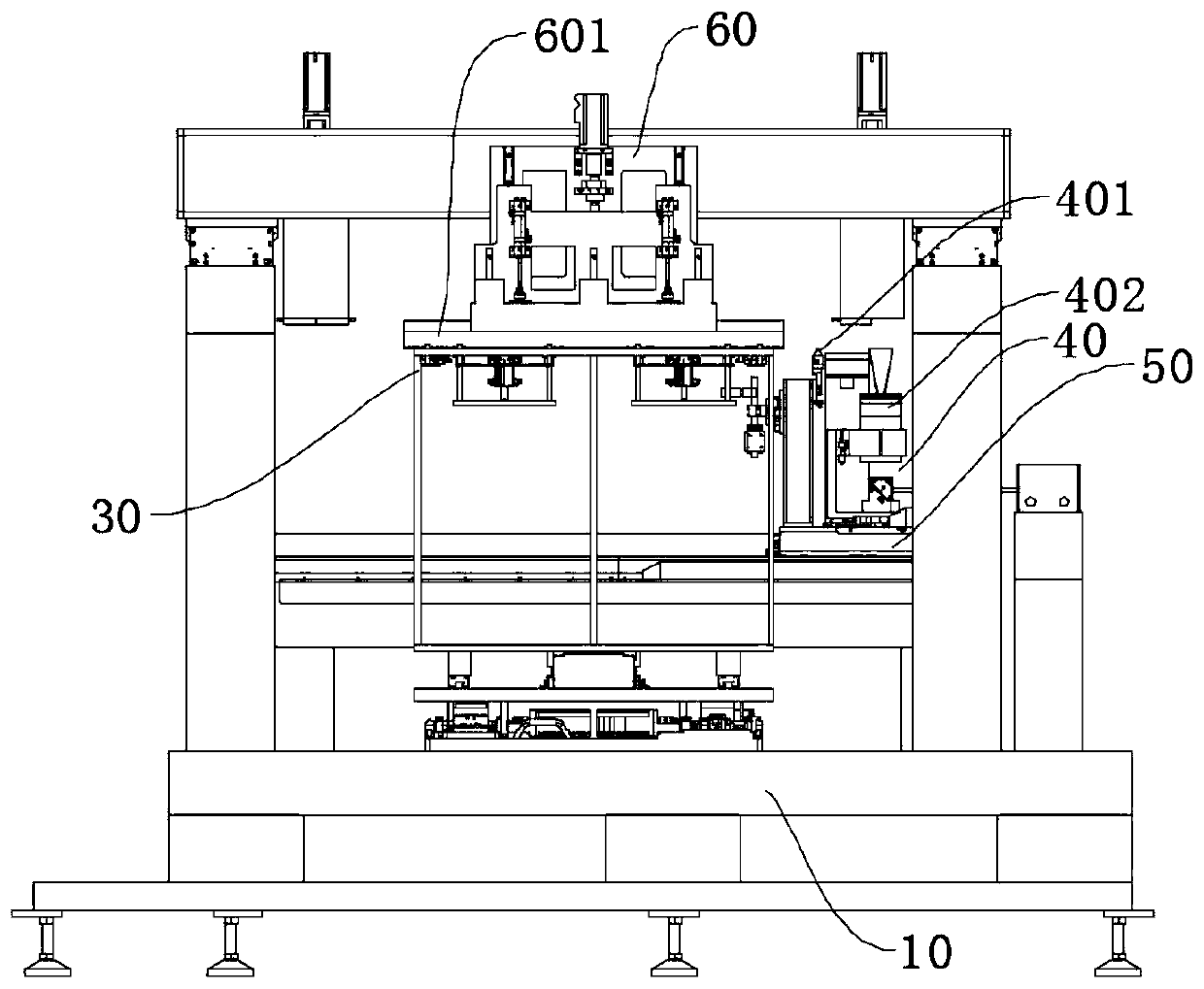

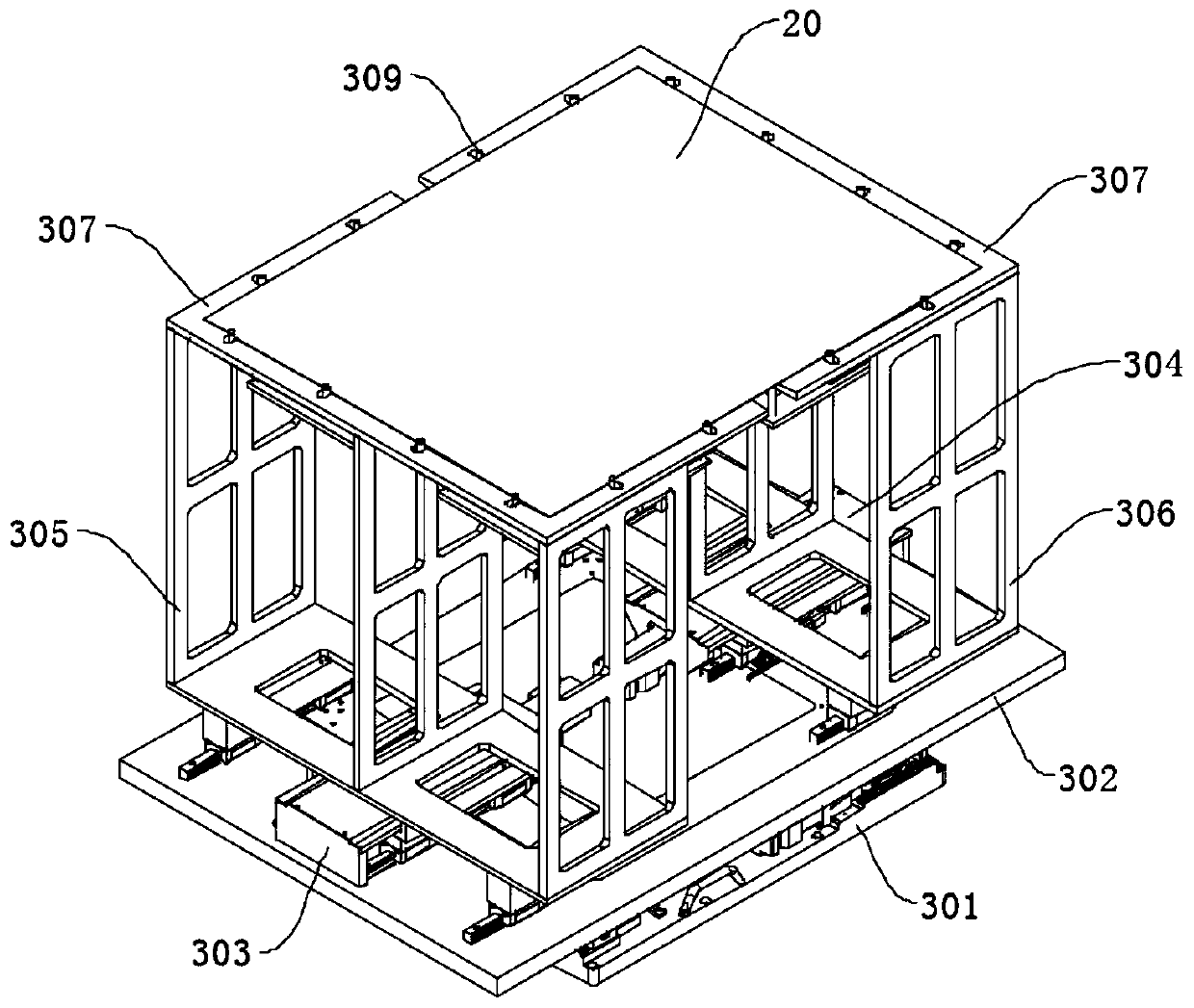

[0035] combine figure 1 and figure 2As shown, a laser cutting device for a non-invasive OLED glass substrate proposed by the present invention includes a stand 10, and the upper end of the stand 10 is provided with a vacuum adsorption workbench 30 for placing the glass substrate 20. Above the stand 10, a A cutting assembly 40 is arranged on the side, and the cutting assembly 40 includes a glass knife 401 for bumping the glass substrate 20 once and a laser lens 402 for cutting the glass substrate 20, and the cutting assembly 40 is fixed on the first X The upper end of the X-axis linear module 50, the first X-axis linear module 50 drives the cutting assembly 40 to pass under the vacuum adsorption workbench 30, and a breaking ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com