An automatic lifting machine for water conservancy projects with increased resistance and anti-detachment

A water conservancy engineering and mechanical technology, applied in the direction of cranes, load hanging components, transportation and packaging, etc., can solve problems such as large air flow, cable wear, and falling objects from high altitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0027] like Figure 1-Figure 5 As shown, the present invention provides a technical scheme of automatic hoisting machinery for water conservancy projects with increased resistance and detachment prevention:

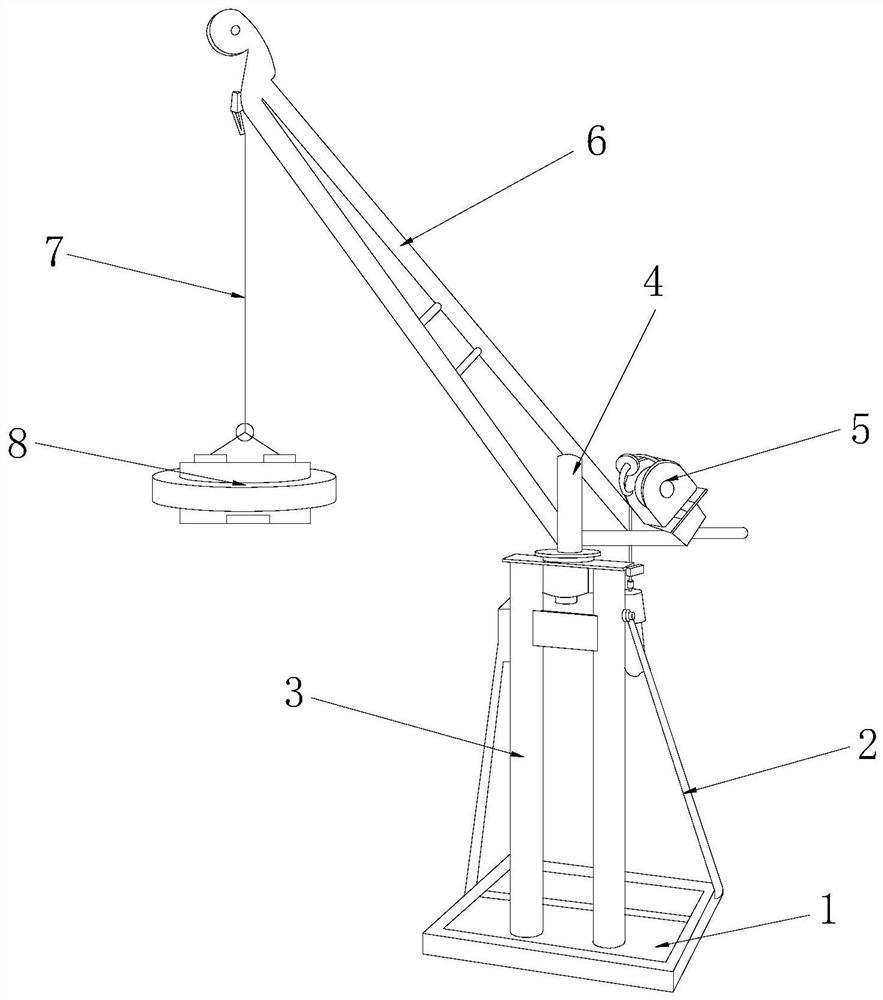

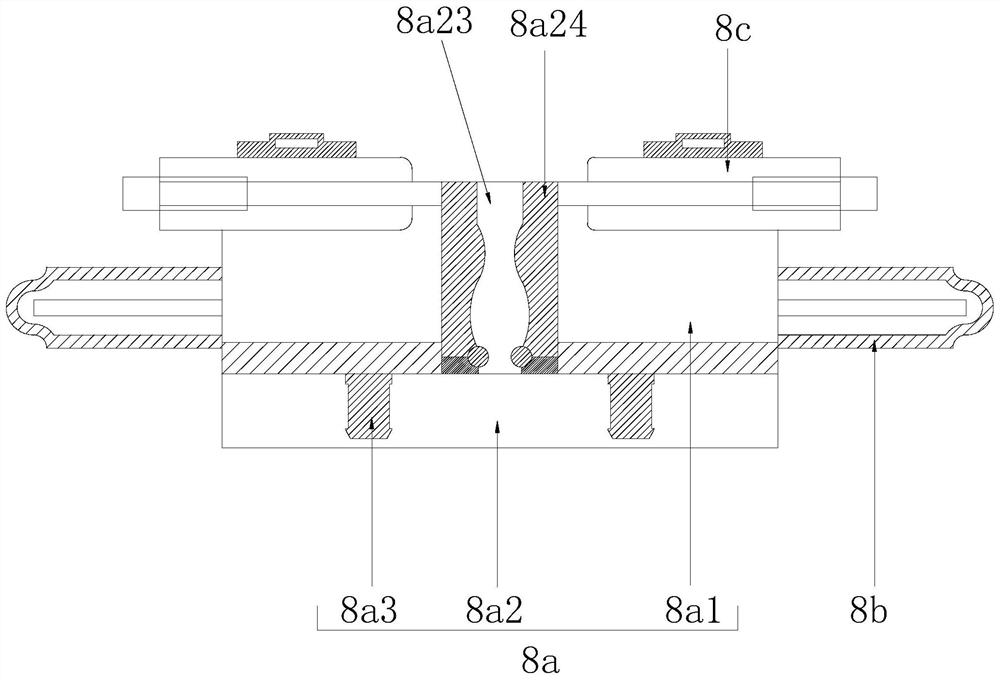

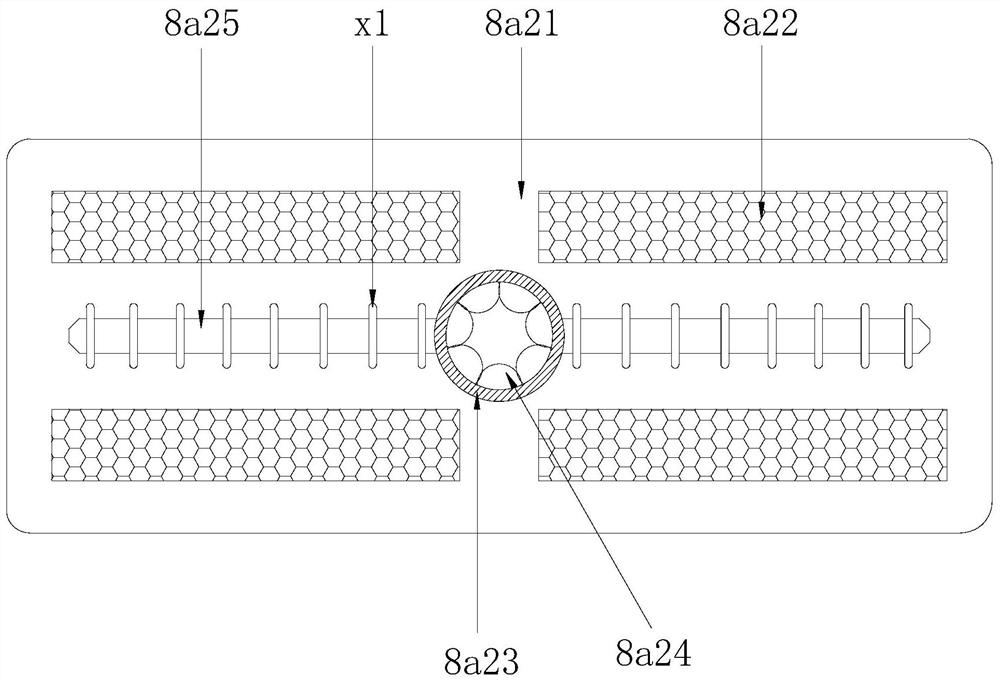

[0028] like Figure 1-Figure 2 As shown, an automatic lifting machine for water conservancy projects with increased resistance and anti-detachment, its structure includes a base 1, a support rod 2, a main rod 3, a movable hub 4, a coiler 5, an adjustment frame 6, a cable 7, Anti-off device 8, the main rod 3 is arranged on the upper surface of the base 1 and connected by electric welding, the support rod 2 is installed on the left and right sides of the main rod 3 and connected with the base 1 by electric welding, and the movable hinge 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com