Modular recyclable exhibition stand

A modular, booth technology, applied in the field of booths, can solve problems such as unfavorable installation and disassembly, pin insertion too tight, unfavorable to public health, etc., and achieve the effect of eliminating gaps, improving stiffness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

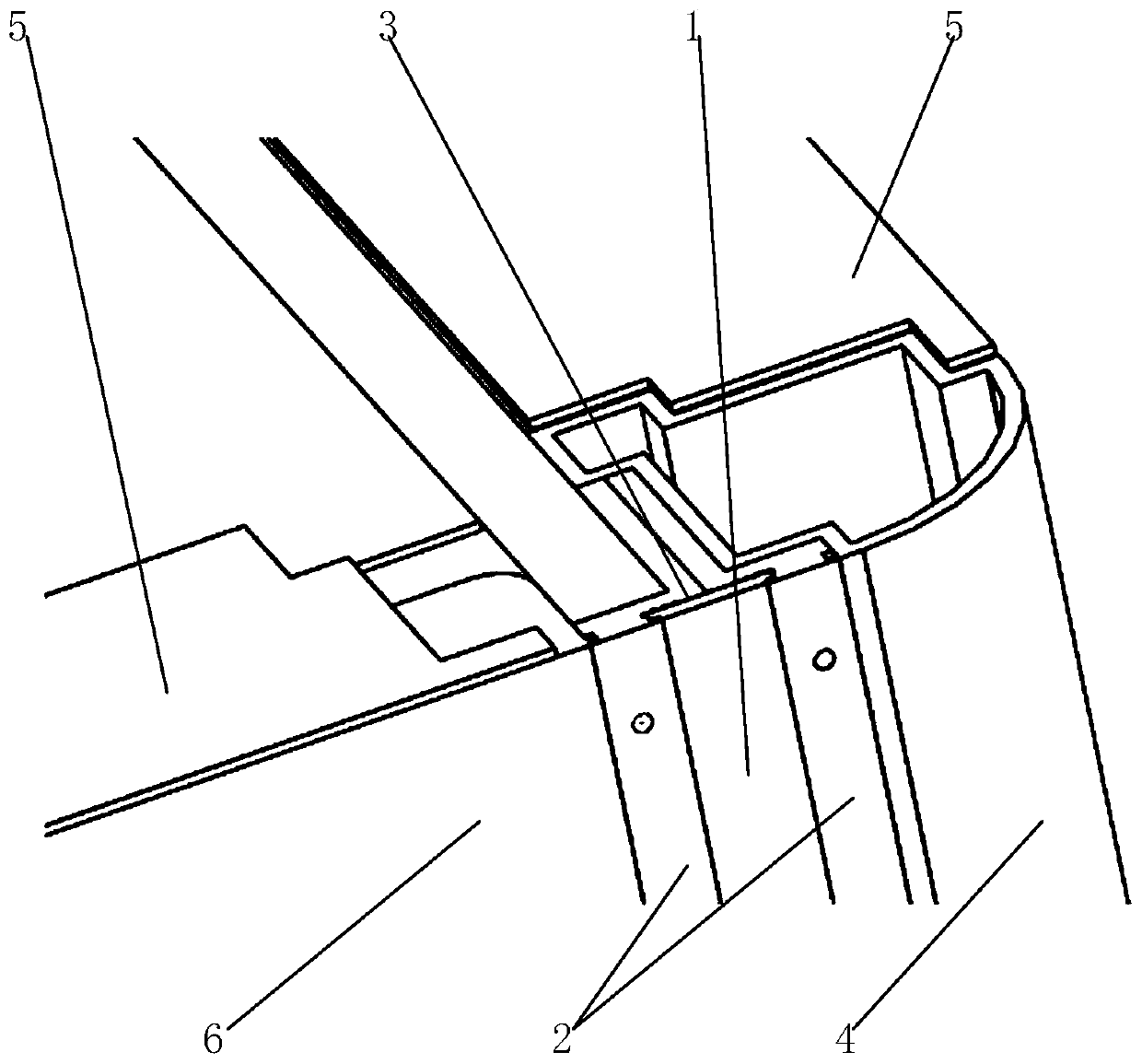

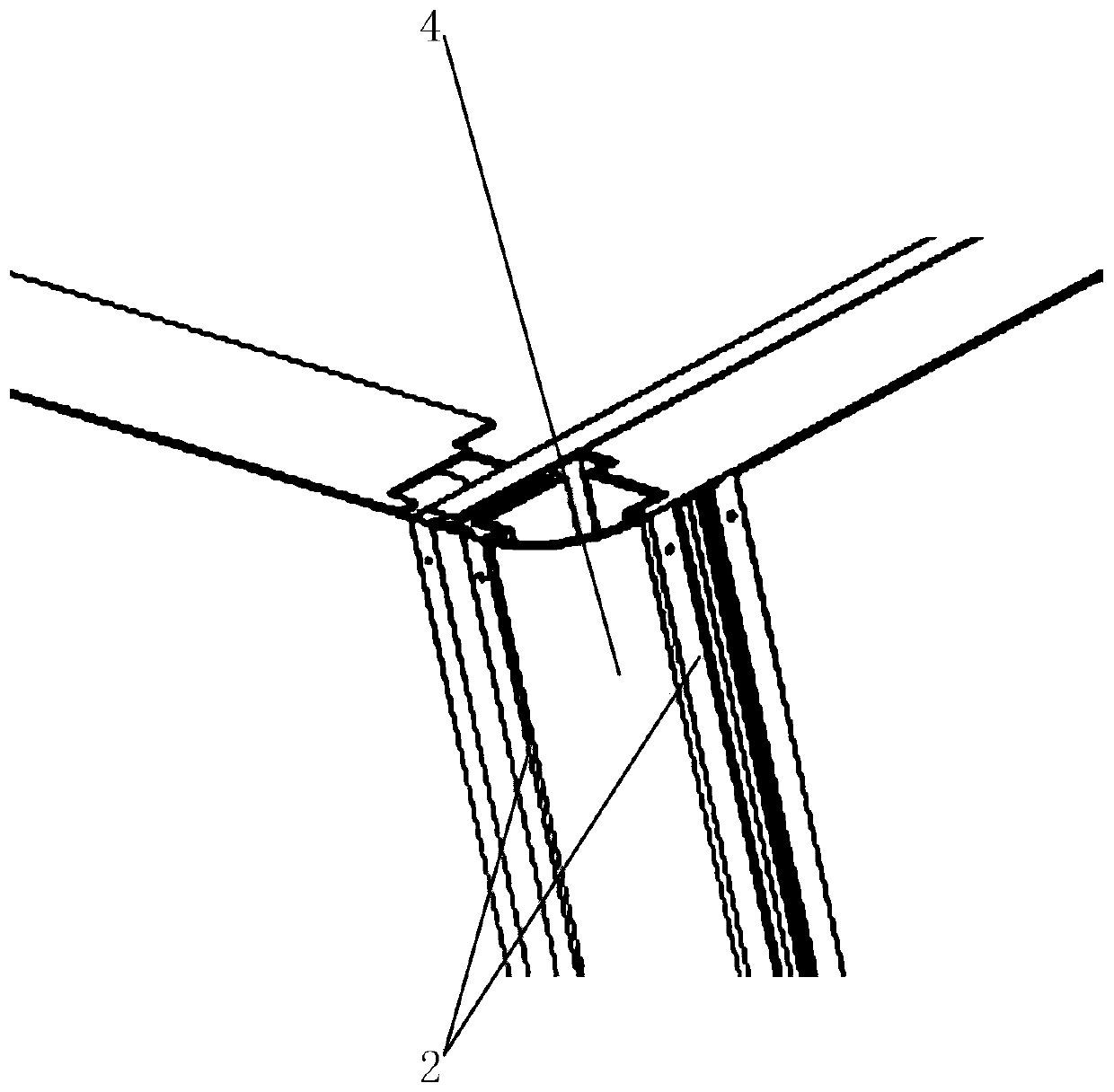

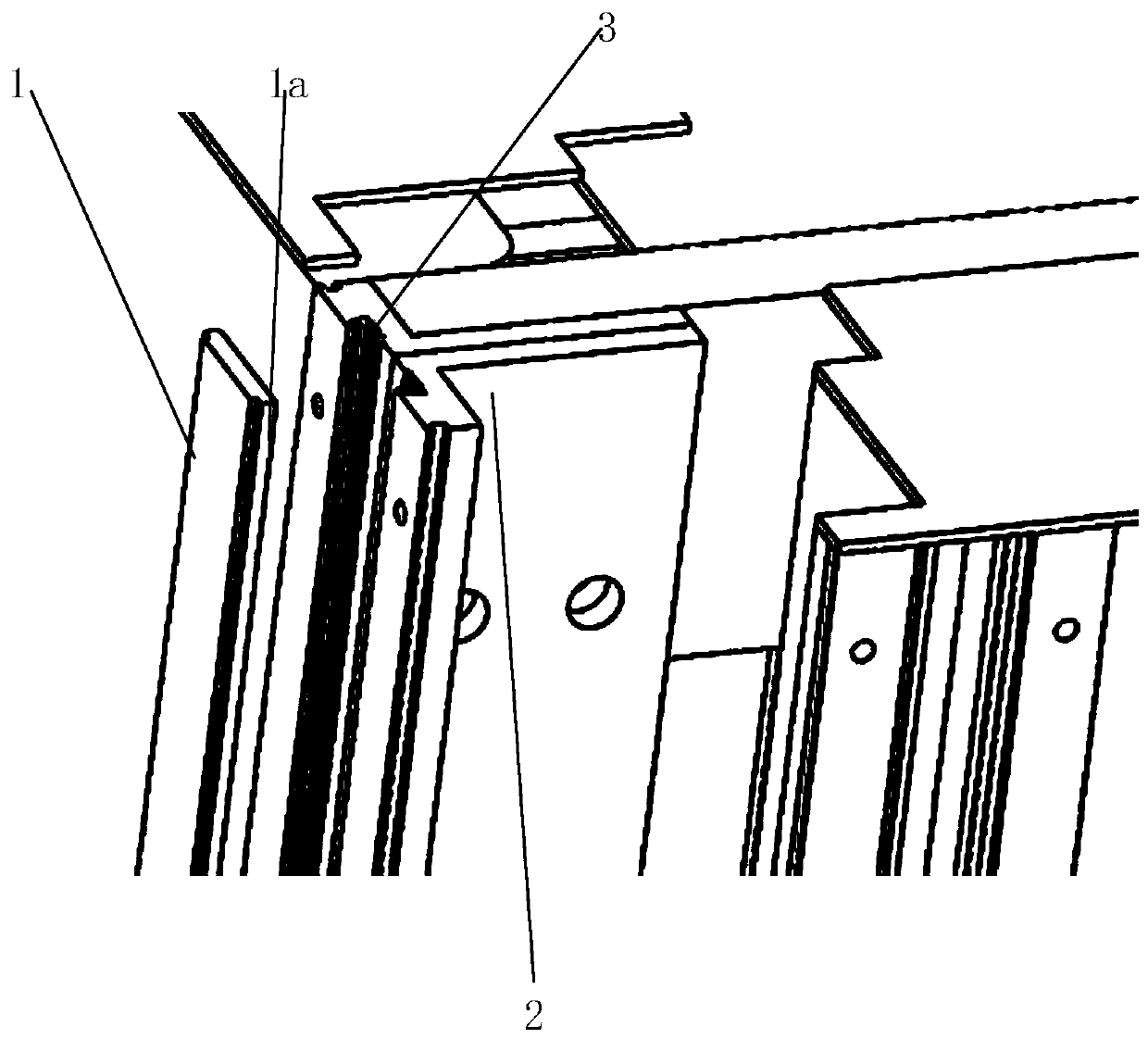

[0027] Such as Figure 1-7 As shown, a modular reusable exhibition stand includes several wall panels 6, cover plate assemblies and several connecting assemblies; a corner support column 4 is arranged at the corner part of the booth, and the two sides of the corner support column 4 are respectively connected to each other through the connection assembly. The two wall panels 6 are connected; the wall panels 6 constituting the plane wall of the booth are connected to each other through a connecting component. In this embodiment, the cover plate assembly is a split structure. Since the corner support column 4 is a hollow structure with an open upper end, a corner cover plate 7 is ad hoc in this embodiment to cover the upper end of the corner support column 4. The corner cover The plate 7 is spliced with the cover plate covering the plane wall, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com