Seamless hinge and machining method thereof

A hinge and seamless technology, which is applied to hinges with pins, door/window accessories, wing leaf parts, etc., can solve the problems of easy wear and load, cumbersome hinge installation, and high cost, so as to reduce metal waste and reduce the use of hinges The effect of high quantity and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

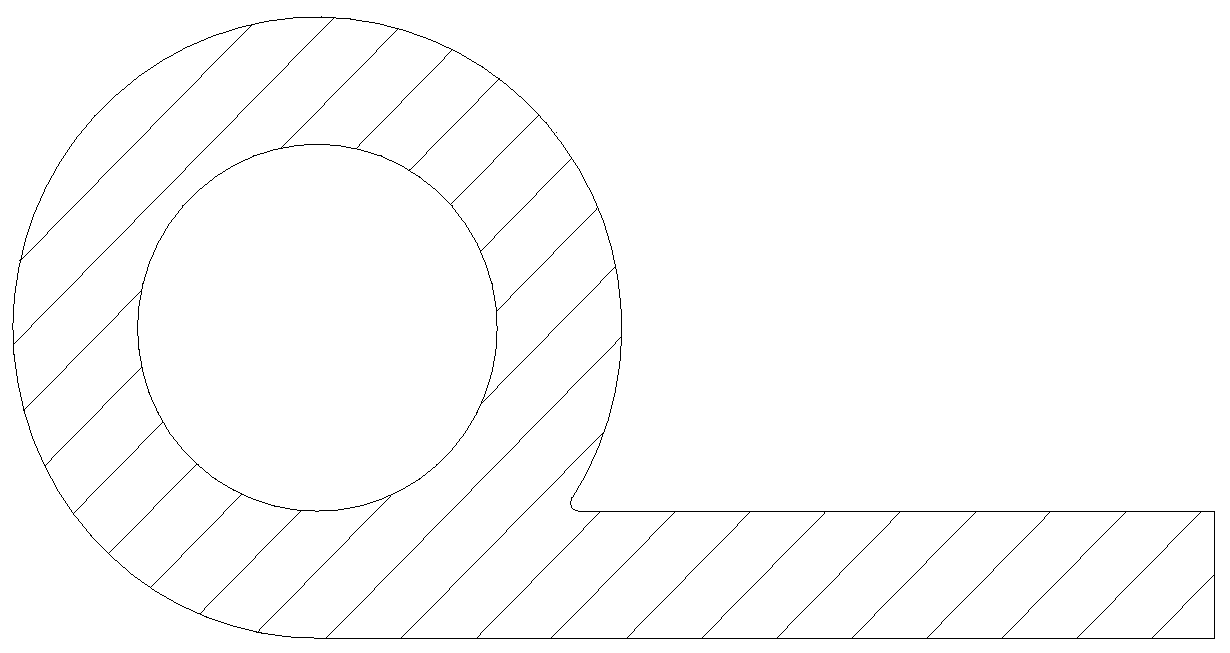

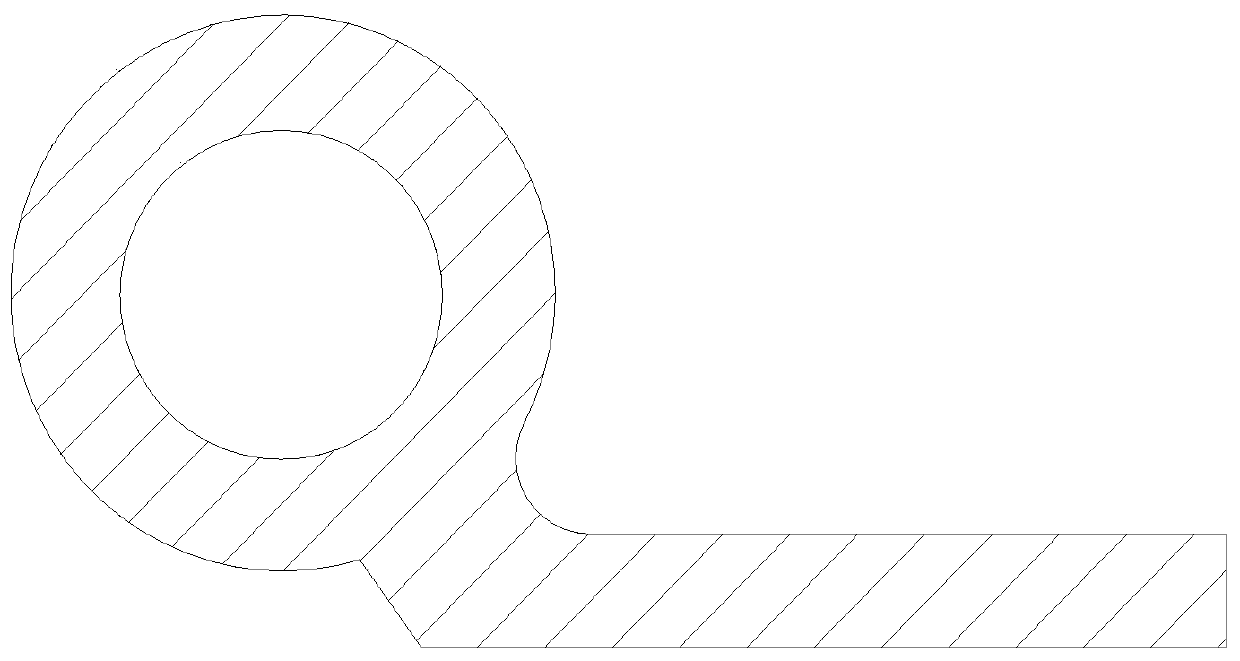

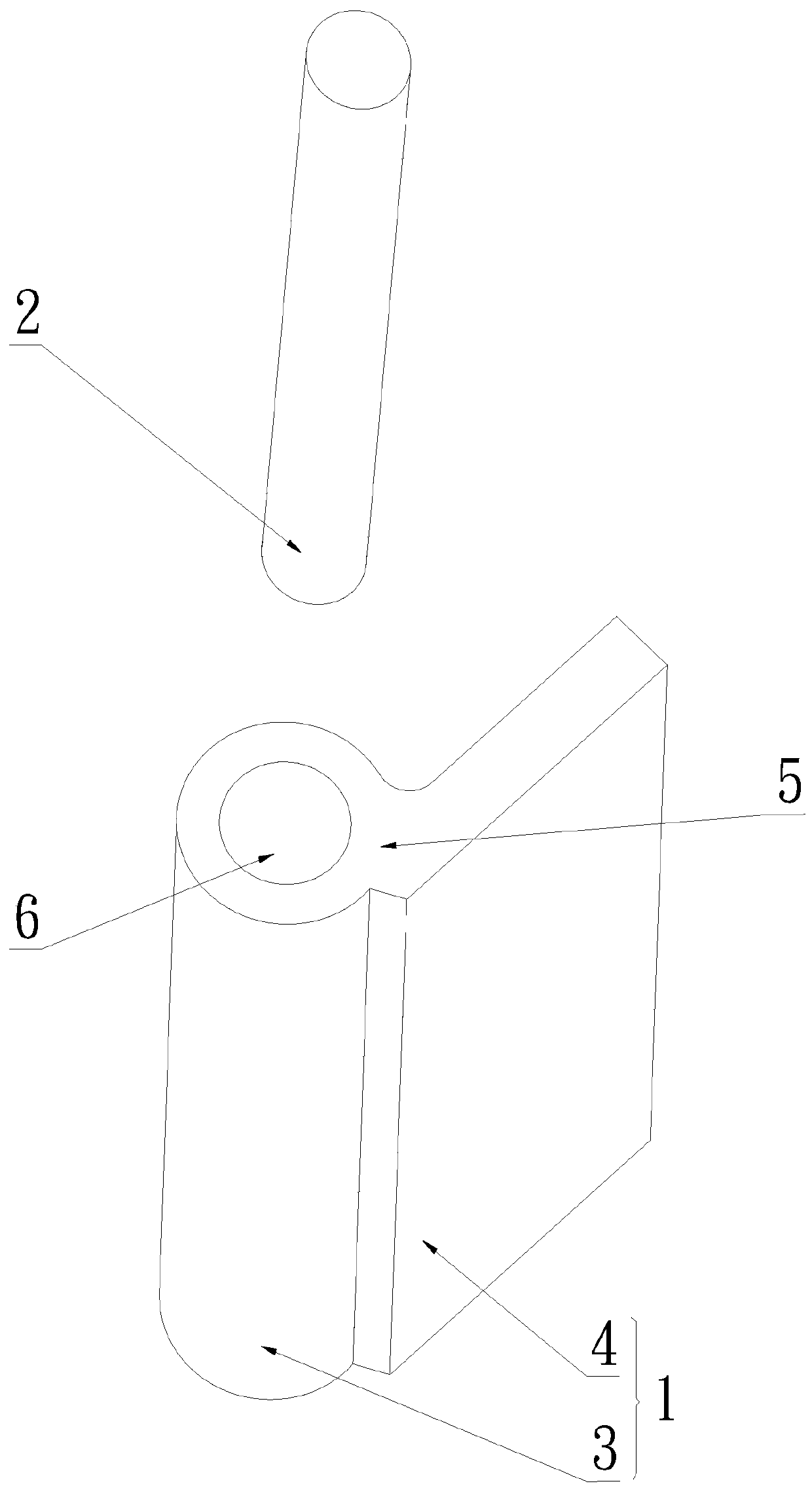

[0047] Such as Figure 1-7 A seamless hinge and its processing method are shown, which include two blades 1 and a rotating shaft 2 in an integrated design; the two blades 1 are sleeved on the rotating shaft 2 and can be opposite to the The rotating shaft 2 rotates; the blade 1 includes a rotating part 3 and a connecting part 4 for connecting with doors and windows; the rotating part 3 is provided with a through hole 6 for inserting the rotating shaft 2; the rotating part 3 and the The connecting part of the connecting part 4 is a smooth curve or a stepped shape or a combination thereof.

[0048]Wherein, the connecting part between the rotating part 3 and the connecting part 4 is a stepped part 5; and an inclined portion 52; the first connecting section is connected to the rotating portion 3; the second connecting section is connected to the connecting portion 4; the protruding portion of the arc portion 51 faces the inclined portion 52; One end of the inclined portion 52 awa...

Embodiment 2

[0063] Such as Figure 1~4 A seamless hinge and its processing method are shown, which include two blades 1 and a rotating shaft 2 in an integrated design; the two blades 1 are sleeved on the rotating shaft 2 and can be opposite to the The rotating shaft 2 rotates; the blade 1 includes a rotating part 3 and a connecting part 4 for connecting with doors and windows; the rotating part 3 is provided with a through hole 6 for inserting the rotating shaft 2; the rotating part 3 and the The connecting part of the connecting part 4 is a smooth curve or a stepped shape or a combination thereof.

[0064] Wherein, the connecting part between the rotating part 3 and the connecting part 4 is a stepped part 5; and an inclined portion 52; the first connecting section is connected to the rotating portion 3; the second connecting section is connected to the connecting portion 4; the protruding portion of the arc portion 51 faces the inclined portion 52; One end of the inclined portion 52 aw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com