Semi-open explosion-proof well cover for launch position

A semi-open manhole cover technology, applied in water conservancy projects, artificial islands, underwater structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

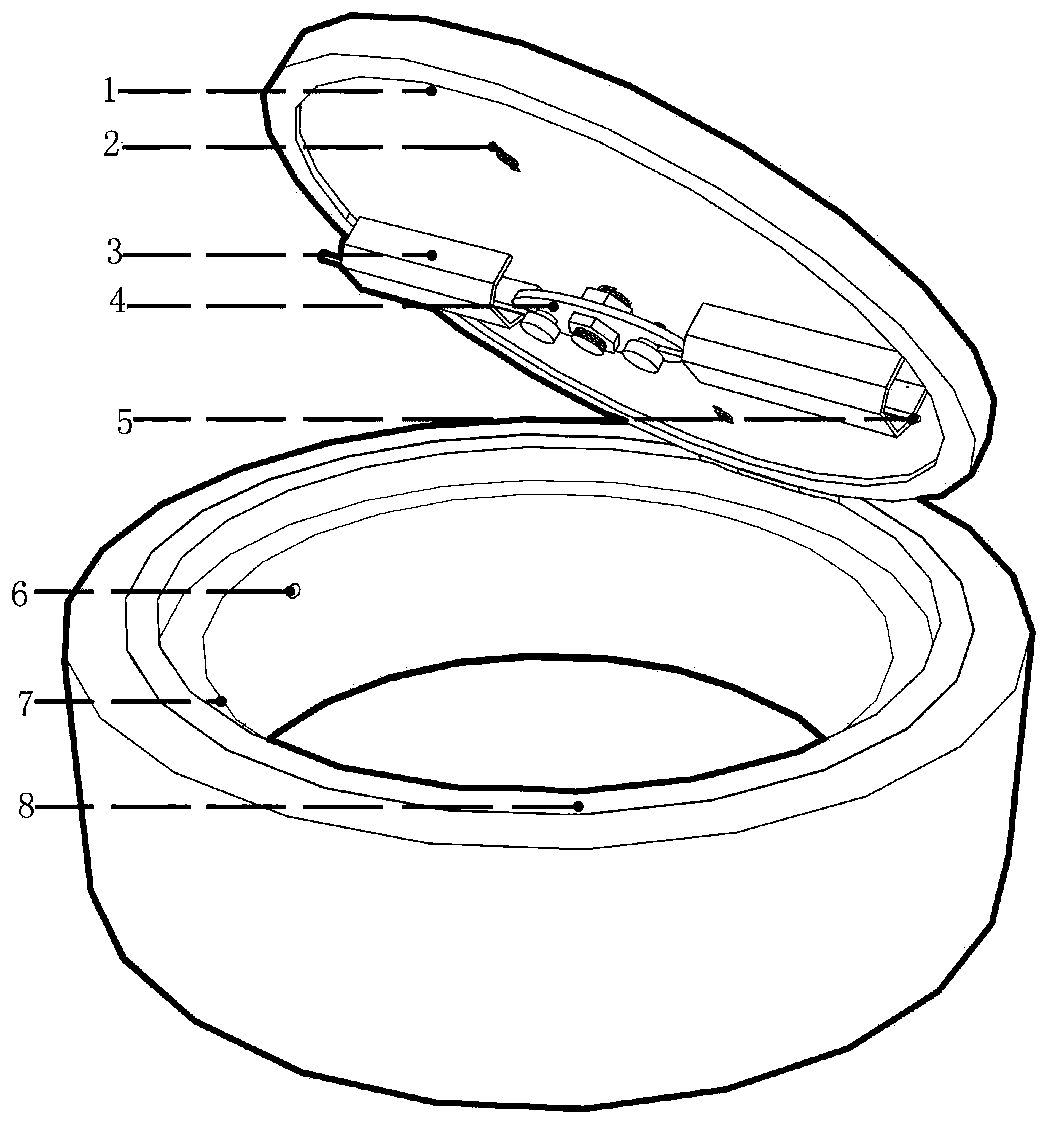

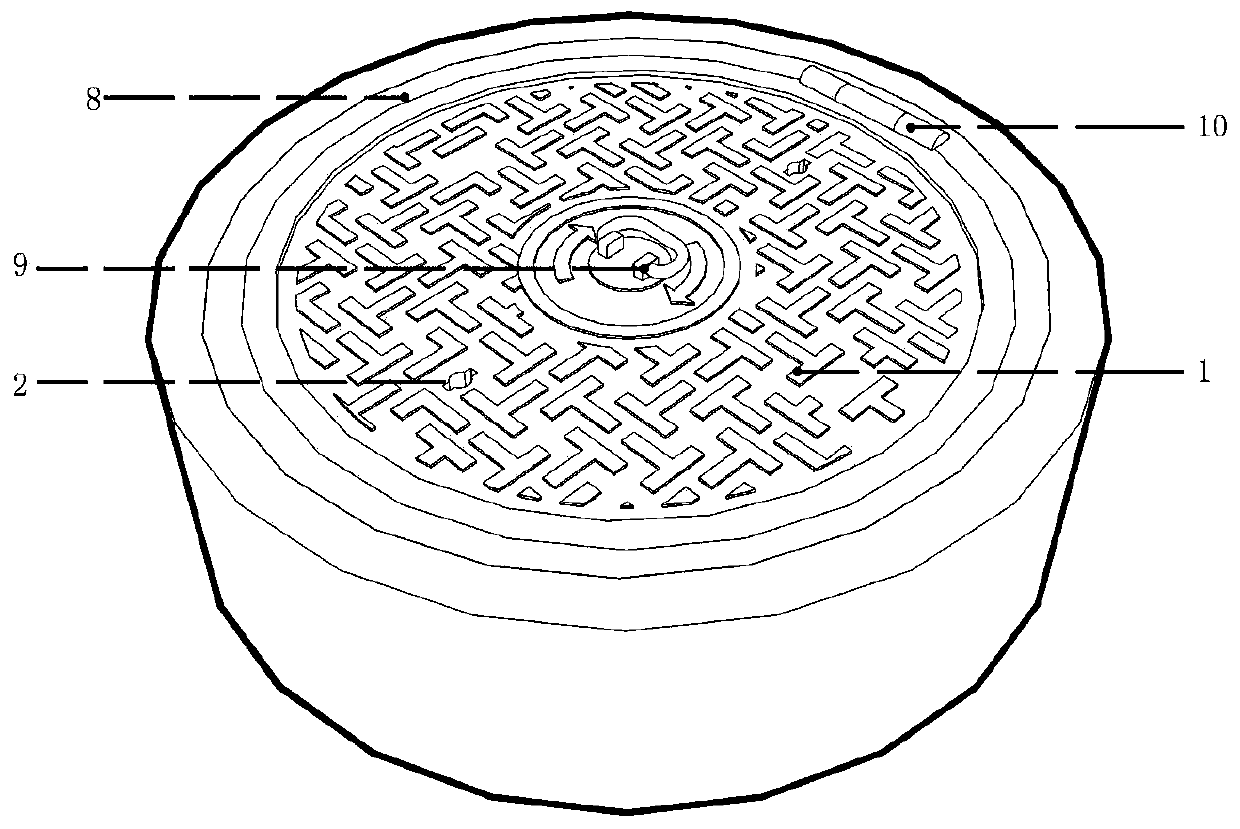

[0019] This embodiment proposes a semi-open explosion-proof manhole cover for launching positions, which consists of a well base 8, a manhole cover 1 and a locking device, and is used in conjunction with a pull ring 9. When building the well, pour a C25 concrete ring beam 7 with a thickness of about 400 mm to 600 mm, and pre-embed four steel bars evenly. The well base 8 is welded to the pre-embedded steel bars and fixed.

[0020] The well cover 1 is connected to the edge of the well base 8 through the hinge 10 arranged on the edge. The main body of the well cover 1 is provided with a plurality of exhaust holes 2 through the front and back, and a pull ring 9 connected with the push rod 4 on the back of the well cover is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com