High-refractive-index wear-resistant hardened coating composition and preparation method of hardened film thereof

A technology of mixture and slurry, applied in the direction of coating, etc., can solve the problems of affecting the strength and light transmittance of composite materials, high stability of phosphoric acid modifiers, difficult to remove modifiers, etc., to achieve a wide range of raw materials and easy availability , broaden the scope of use, the effect of high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Weighing 10 grams of basic zirconium carbonate and dissolving excess alkali in water for hydrothermal reaction, after the reaction is completed, filter and wash the filter cake until the pH is about 10;

[0041] 2) Take all the filter cake, add 2 ml of methyl acrylate and 20 ml of water into the bottle, stir and react at 60 degrees Celsius for 12 hours, filter and wash the filter cake twice after the reaction is completed;

[0042] 3) drying the filter cake for 10 hours under an environment of 70 degrees Celsius to obtain zirconia powder;

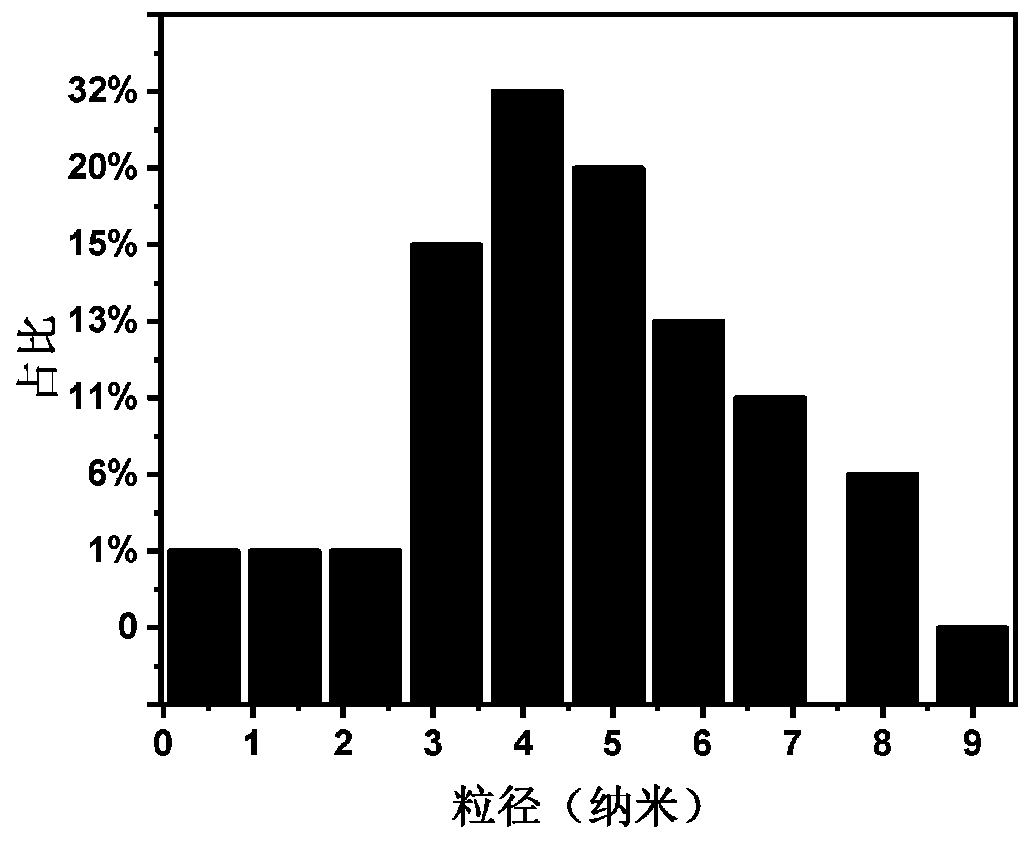

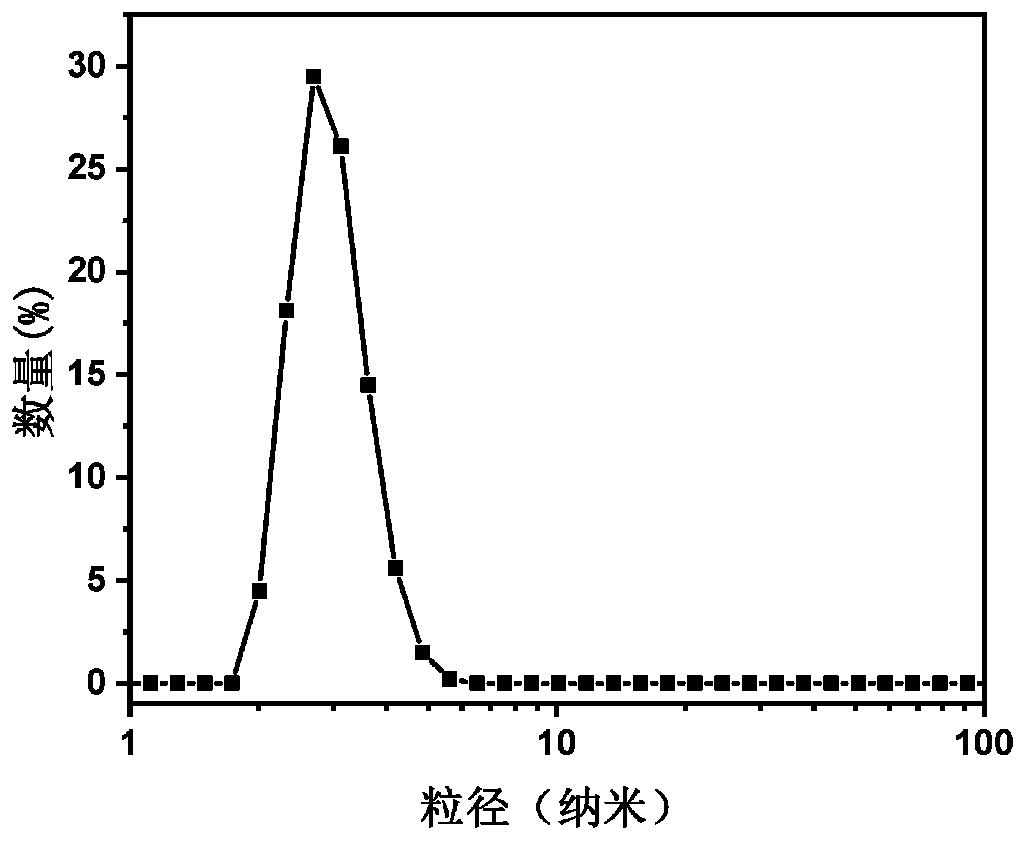

[0043] 4) Add the powder into tetrahydrofuran to form a dispersion with a solid content of 10 wt%, add 10 microliters of N-B-(aminoethyl)-Γ-aminopropylmethyldimethoxysilane, and add a magnet at the bottom of the bottle Finally, put it on a magnetic stirrer, stir and react at a speed of 100 rpm for 4 hours, and obtain a high-dispersion organic phase nano-zirconia particle dispersion of the product. Wherein the particle size of the...

Embodiment 2

[0046] 1) Weighing 10 grams of basic zirconium carbonate and dissolving excess alkali in water for hydrothermal reaction, after the reaction is completed, filter and wash the filter cake until the pH is about 10;

[0047] 2) Take all the filter cake, add 2 ml of methyl methacrylate and 30 ml of water into the bottle, stir and react at 60 degrees Celsius for 24 hours, filter and wash the filter cake twice after the reaction is completed;

[0048] 3) drying the filter cake for 10 hours under an environment of 70 degrees Celsius to obtain zirconia powder;

[0049] 4) Add the powder into tetrahydrofuran to make a dispersion with a solid content of 10wt%, add 10 microliters of Γ-aminopropyltriethoxysilane, add magnets to the bottom of the bottle and place it on a magnetic stirrer, at 100 rpm The reaction was stirred at a speed of 1 minute for 1 hour to obtain a high-dispersion organic phase nano-zirconia particle dispersion. The particle size of the nanoparticles under the electro...

Embodiment 3

[0052] 1) Weighing 20 grams of zirconium oxychloride hydrate and dissolving excess alkali in water for hydrothermal reaction, after the reaction is completed, filter and wash the filter cake until the pH is about 8;

[0053] 2) Take all the filter cake, add 1 ml of methacrylic acid and 40 ml of water into the bottle, stir and react at 70 degrees Celsius for 4 hours, filter and wash the filter cake twice after the reaction is completed;

[0054] 3) drying the filter cake for 8 hours under an environment of 80 degrees Celsius to obtain zirconia powder;

[0055] 4) Add the powder into toluene to make a dispersion with a solid content of 10wt%, add 10 microliters of N-B-(aminoethyl)-Γ-aminopropylmethyldimethoxysilane, and add a magnet at the bottom of the bottle Finally, place it on a magnetic stirrer, stir and react at a speed of 120 rpm for 4 hours, and obtain a high-dispersion organic phase nano-zirconia particle dispersion of the product. Wherein the particle size of the nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com