A prepreg for ooa process meeting en45545 flame retardant standard

A prepreg and process technology, which is applied in the field of prepreg for OoA process, can solve the problems of adverse effects of resin reactive fiber wettability, changing the overall polarity of resin, and high cost of epoxy resin, so as to achieve wide applicability and improve The effect of interface polarity and excellent mechanical properties

Active Publication Date: 2022-05-31

HENGSHEN

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because it is grafted on the polar group of epoxy resin, the overall flame retardant content is generally relatively low. Generally, when introducing this type of flame retardant resin, the required amount is as much as 60 parts or more. In addition, it is flame retardant itself. The cost of agent grafted epoxy resin is high. Although the addition of flame retardant powder can be reduced to a certain extent, the introduction of flame retardant groups into epoxy resin branch chains increases the reaction steric hindrance and changes the overall polarity of the resin. Reactivity, which adversely affects the reactivity of the final resin and the wettability of the fibers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

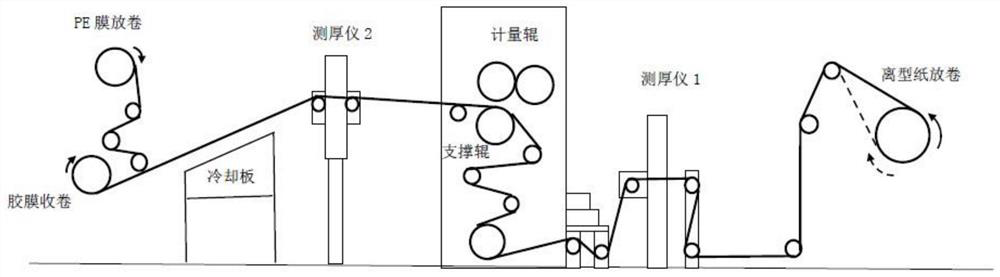

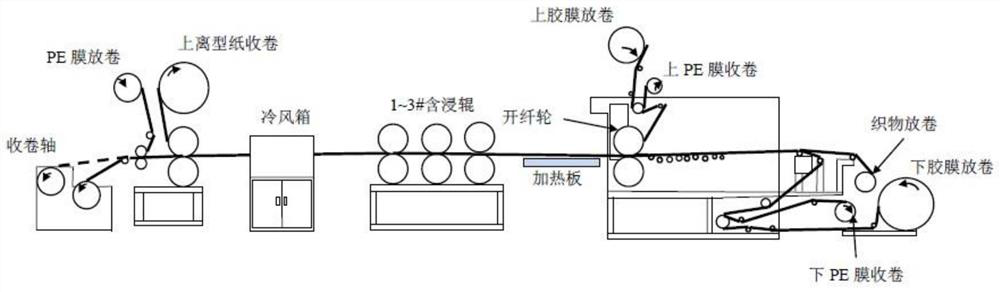

[0040] When the flame retardant resin substrate a is coated, the temperature of the coating film metering roll is controlled at 72 ° C, the gap between the measuring rolls is 0.12mm, and the support

Embodiment 2

[0044] When the flame retardant resin base b is coated, the temperature of the coating film measuring roll is controlled to be 74 ° C, and the gap between the measuring rolls is 0.12 mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a prepreg for OoA process meeting the flame retardant standard of EN45545, which includes carbon fiber and a flame retardant resin matrix; There are at least two fuels. Through the optimal combination of flame retardants, the flame retardant effect is achieved at different stages of combustion, so that the flame retardant resin not only meets the HL1 or HL2 level in the EN45545 flame retardant standard, but also applies to the low-cost OoA process, reducing the impact on the mechanical properties of the final product. The impact of the prepreg makes it have excellent mechanical properties after curing. At the same time, the interface modifier improves the polarity of the interface between the flame retardant and the resin, allowing the resin to fully contact and infiltrate the fiber after fully infiltrating the powder, realizing the stress transfer between the fiber and the resin, and giving full play to the excellent mechanical properties of carbon fiber composites. performance characteristics.

Description

A prepreg for OoA process that meets EN45545 flame retardant standard technical field The present invention relates to a kind of prepreg, be specifically related to a kind of OoA process prepreg that meets EN45545 flame retardant standard It belongs to the technical field of flame retardant. Background technique [0002] At present, the fire protection standards for rail transit locomotives at home and abroad mainly include the European Union EN45545: 2013 series of standards "Iron Road Applications - Fire Protection of Railway Vehicles", BS 6853:1999 "General Specification for Fire Protection for Design and Construction of Passenger Trains", UK, Germany DIN5510: 2009 series of standards "Fire protection measures for rail vehicles", UIC 564‑2 "Railway passenger cars or international railway vehicles" of the International Union of Railways Fire Protection and Fire Protection Regulations for Similar Vehicles Used in Rail Links, NFPA 130 of the United States, Fixed Rail T...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L63/04C08L63/00C08K3/22C08K7/06C08K3/32C08K3/38C08K5/3492C08J5/24

CPCC08J5/24C08J2363/04C08J2463/00C08K2003/2227C08K2003/323C08K2003/387C08K5/34928

Inventor 李志涛钱京尹国强单瑞俊毛慧文

Owner HENGSHEN

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com