A method for making a cross transformer box-shaped node

A production method and box-type technology, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of great influence on welding quality and appearance, complex splicing and welding process, and inability to complete internal welding, etc., to achieve convenience Welding operation, optimized assembly process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

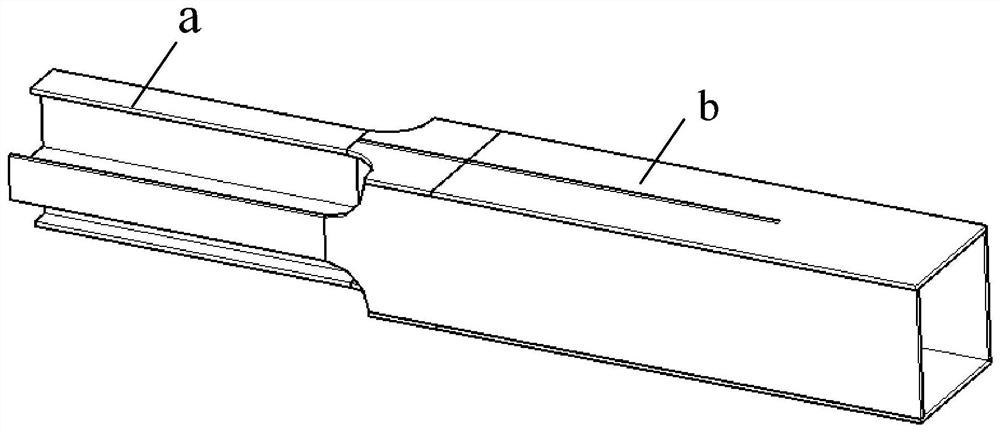

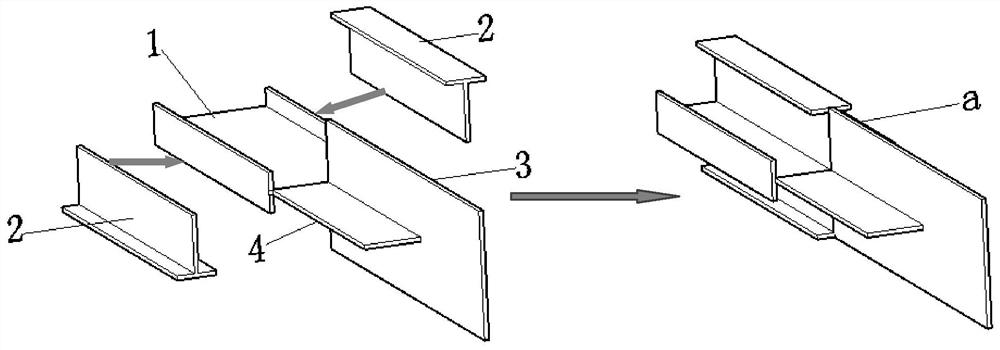

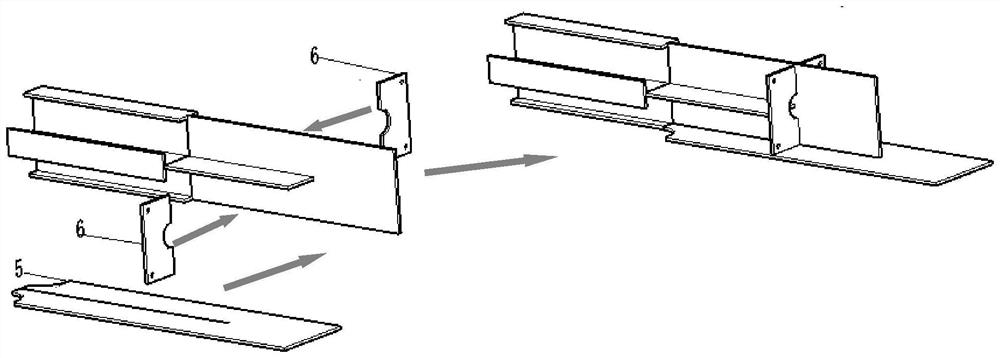

[0035] Embodiments of the present invention will now be described with reference to the drawings. The method of manufacturing a cross-guided box-type node provided by the present invention is mainly suitable for the transition joints of concrete and steel structures in high-rise buildings, and the cross-section of the cross section is combined with the outer type cross section of the box column, but cannot be limited to this. It can be used in other identical or similar construction processes.

[0036] The present invention focuses on the assembly method of the cross-like box type node, and is not described with respect to the comparable mature steel sheets, and the specific dimensional grooves are not described below, and the present invention will be further described below.

[0037] Combine Figure 1 - Figure 5 As shown, a cross-changing box node production method, including the assembly and splicing of the cross column and box column, the steps are as follows:

[0038] Step 1: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com