Dry-wet separated lithium battery pack thermal management system and method

A dry-wet separation and management system technology, applied to secondary batteries, battery/fuel cell control devices, circuits, etc., can solve problems such as low heat dissipation efficiency, large battery damage, and large safety hazards, achieving high heat dissipation efficiency and ensuring The effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

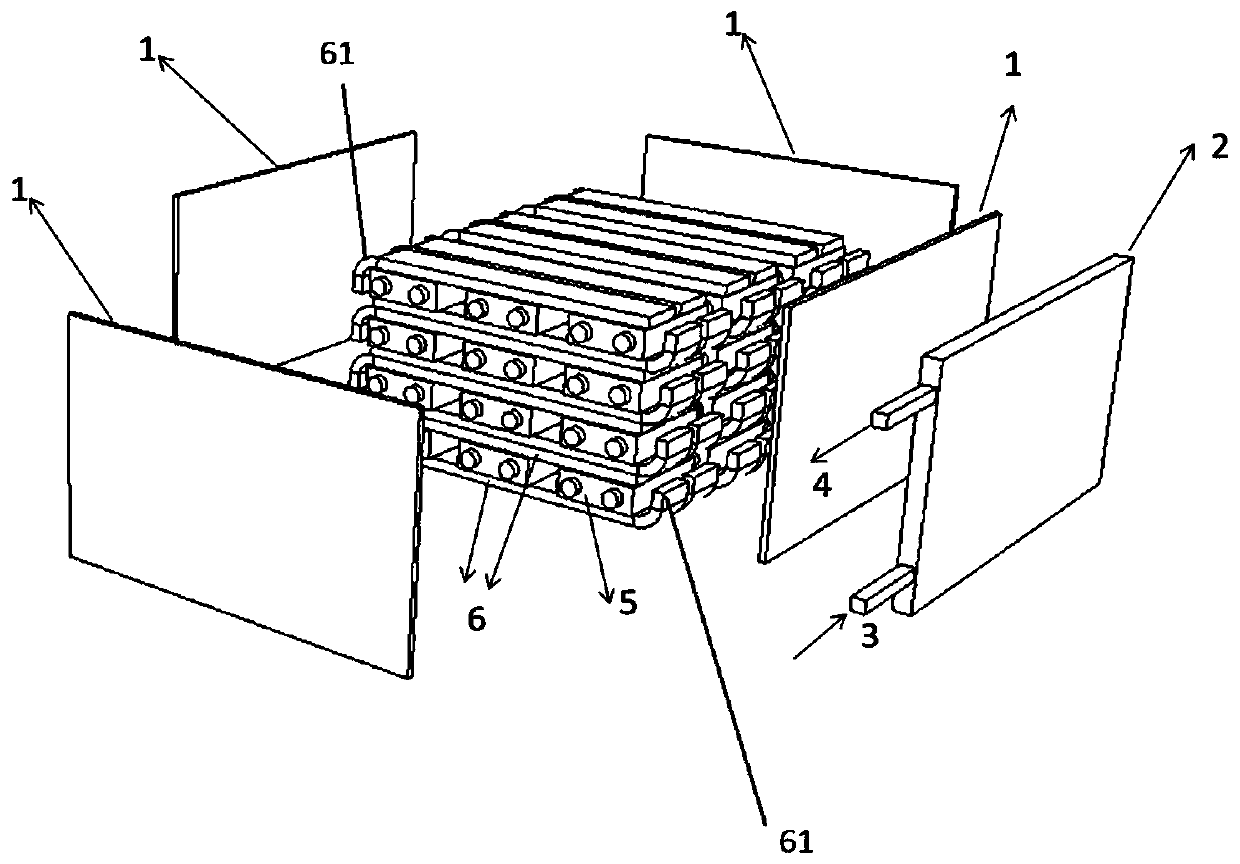

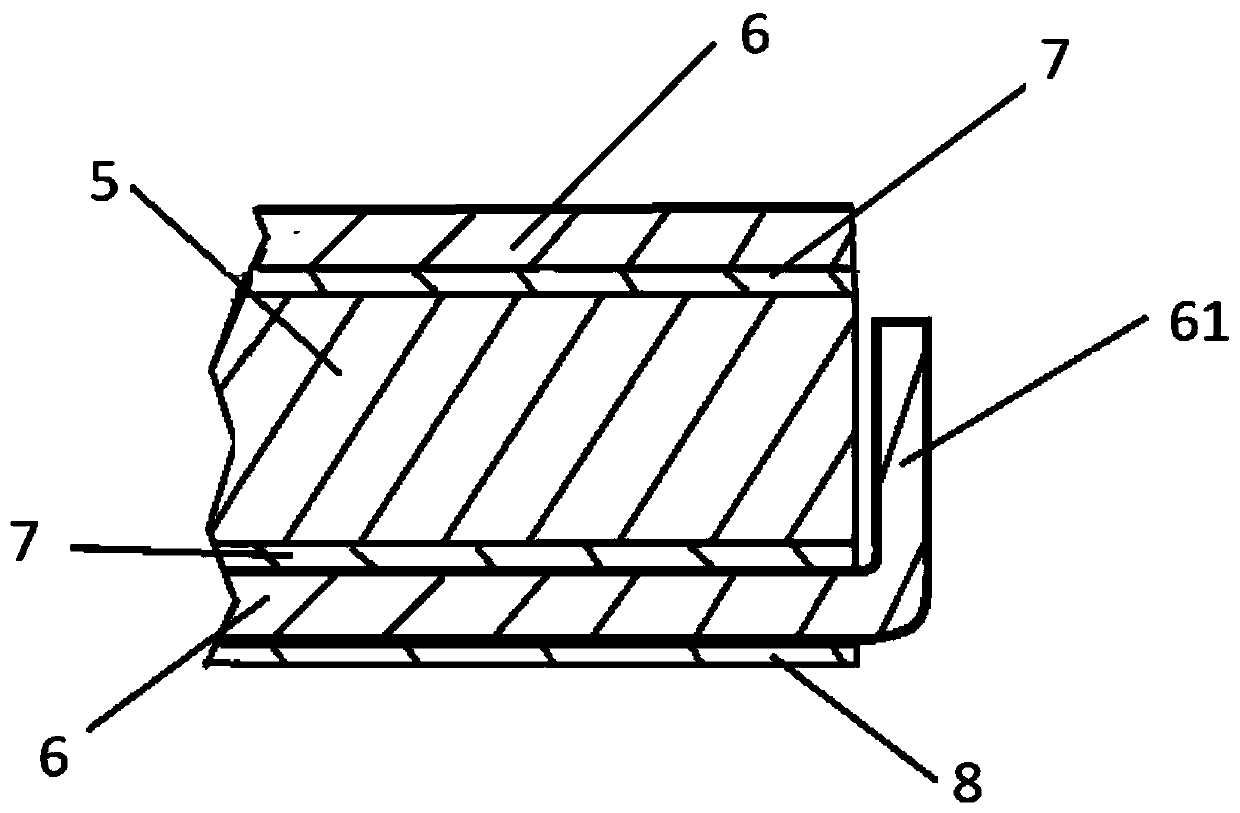

[0036] Such as Figure 1-3As shown, a dry-wet separation battery pack thermal management system in this embodiment includes horizontal cells inside the battery pack and a liquid-cooled plate-tube heat exchanger 2 attached to the outside of the battery pack casing 1. The batteries in the battery pack are divided into four layers, each layer has three vertically and three horizontally. The upper and lower surfaces of the three battery units 5 in each horizontal layer are attached to two sets of micro heat pipe arrays 6 extending in the lateral direction. The micro heat pipe array 6 is a flat heat conductor with a porous structure formed by extrusion of a metal material, and has a plurality of micro heat pipes arranged side by side that are not connected to each other and operate independently, and the hydraulic diameter of each micro heat pipe is 1mm. The internal phase change working medium is a non-conductive medium. A solid metal strip with a width of 3-10 mm and the same l...

Embodiment 2

[0045] The internal structure of the battery of this embodiment is as Figure 4 As shown, only the lower side has the micro heat pipe array, both sides have the protruding part 61 and are bent upwards, and other structures and principles are consistent with the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com