A current-carrying friction test method for a double-arm micro-load brush

A current-carrying friction and testing method technology, which is applied in the direction of measuring devices, instruments, and mechanical devices, can solve the problems of small brush wire diameter, inability to clamp, small friction load and friction force, etc., and achieve reliable and fast calculation Easy to install and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following examples further illustrate the content of the present invention, but should not be construed as limiting the present invention. Without departing from the essence of the present invention, the modifications and substitutions made to the methods, steps or conditions of the present invention all belong to the scope of the present invention.

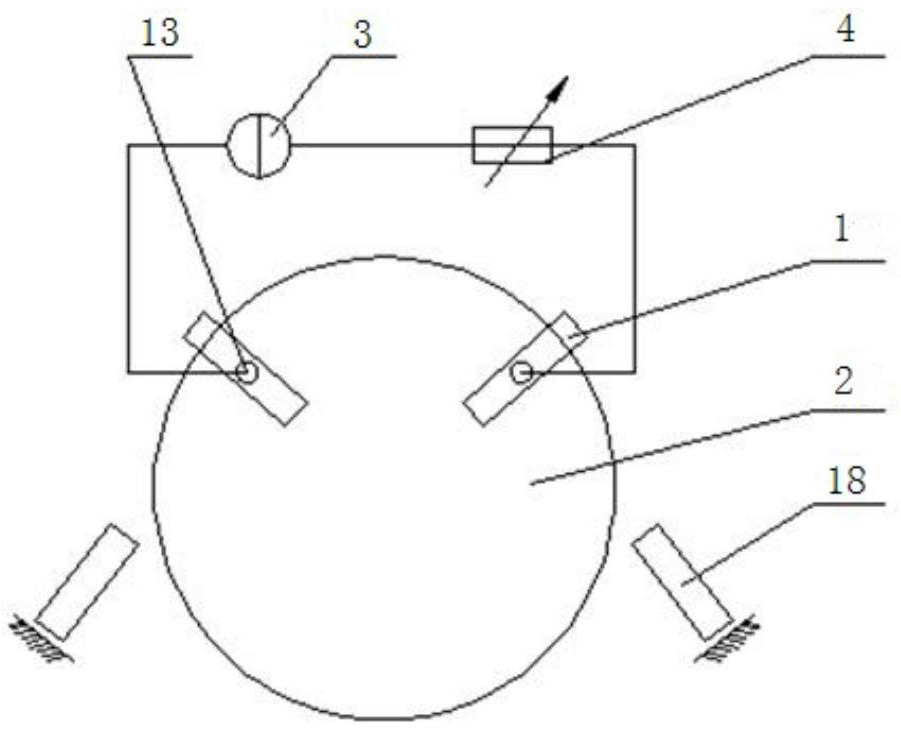

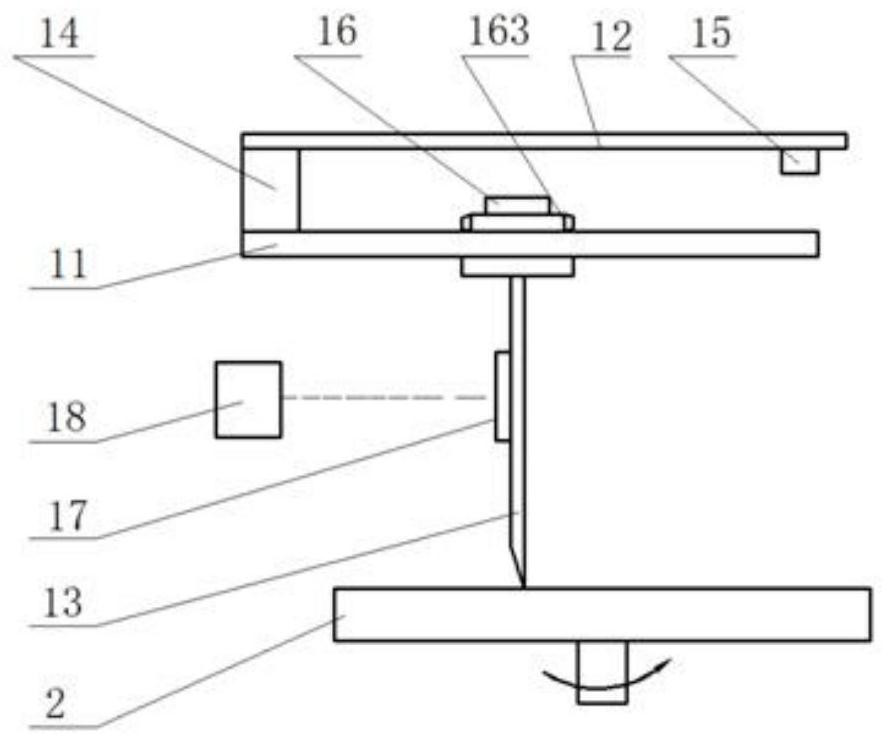

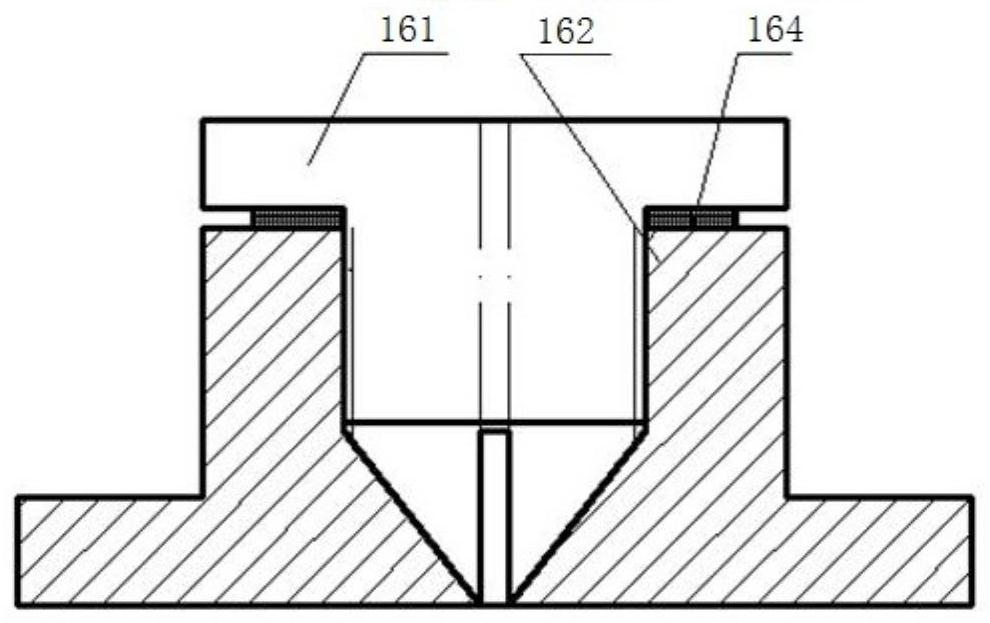

[0052] like Figure 1-3 As shown, the present embodiment provides a dual-arm micro-load brush current-carrying friction test device, which includes two groups of flexible arm assemblies 1, and the flexible arm assembly 1 includes a flexible arm 11, a vertical motion platform 12 and a brush bundle 13. The arm 11 is arranged parallel to the vertical motion platform 12, the axis of the flexible arm 11 projected vertically onto the current-carrying plate 2 passes through the center of the current-carrying plate 2, and the flexible arm 11 is connected to one end of the vertical motion platform 12 through a rigid support 14,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com