A method for testing muzzle efficiency

An efficiency test, muzzle technology, applied in weapon testing, offensive equipment, weapon accessories, etc., to achieve the effect of high precision, easy operation, and reduced measurement links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

[0028] The invention provides a method for testing muzzle efficiency, which specifically includes the following steps:

[0029] Step 1. Measure the weight M of the recoil part of the gun with and without the muzzle brake - , M 0 ;

[0030] Step 2, choose and match the special charge reduction charge, prepare the ammunition, and measure the weight ω′ of the charge reduction charge.

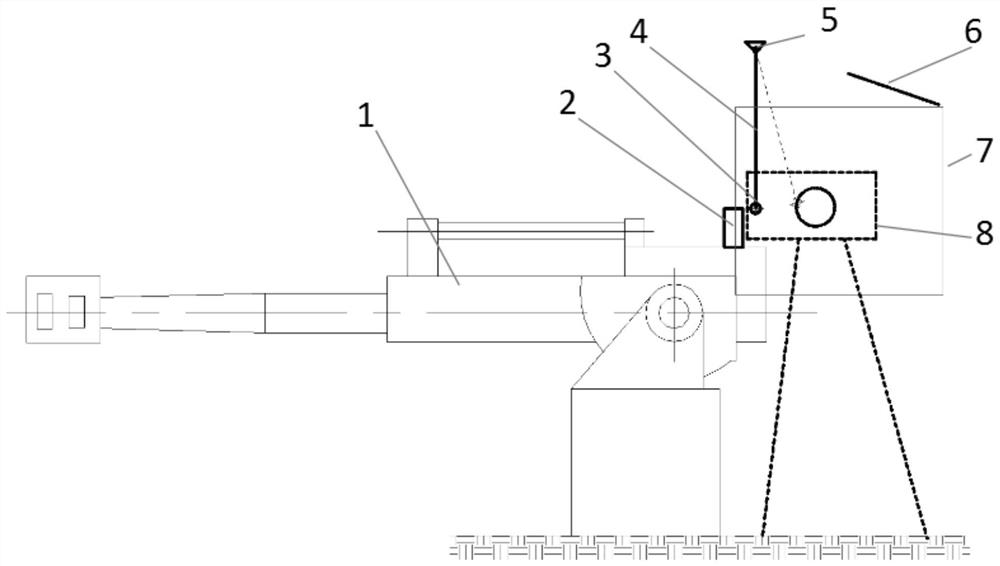

[0031] Step 3, making the collision plate 2, the steel ball 3, the rope 4, the bracket 5, the container 6, and the background plate 7;

[0032] The collision plate can be installed on the cannon 1, its surface is quenched, its thickness is not less than 30mm, and it is weighed (the weight is included in the weight of the recoil part);

[0033] There is a φ1 through hole in the middle of the steel ball 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com