Suction and exhaust valve floating ball and suction and exhaust valve composed of floating ball

An intake and exhaust valve, floating ball technology, applied in the valve shell structure, valve operation/release device, lift valve and other directions, can solve problems such as failure to exhaust, poor reliability, and collapse of the pipeline system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

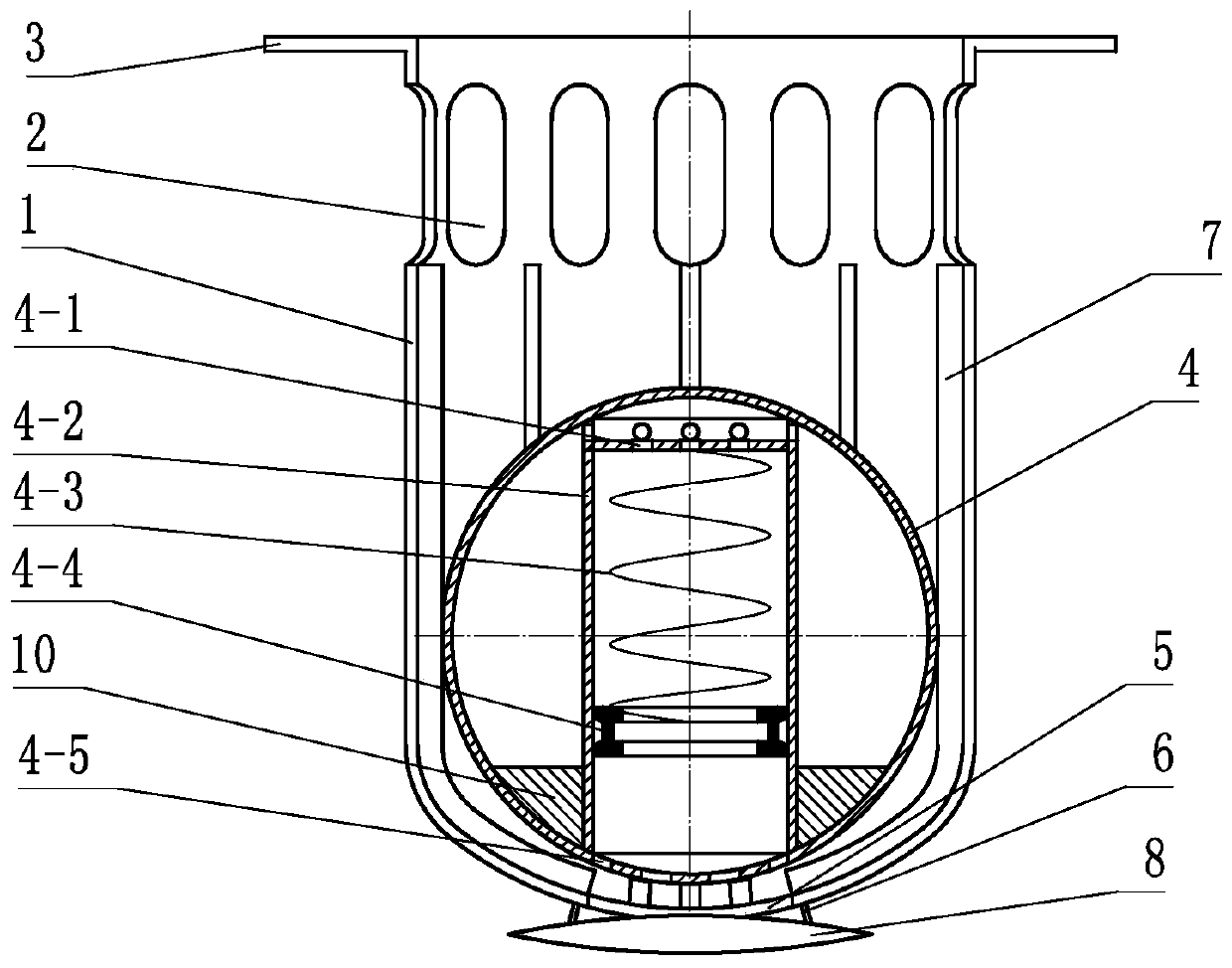

[0030] Embodiment 1: refer to figure 1 with 2 , is a structural schematic diagram of Embodiment 1 of the present invention, the intake and exhaust valve float includes a float housing 4, and the float housing 4 is provided with an adjustment mechanism that adapts to the external pressure. The piston-like mechanism in the inner cavity, the piston-like mechanism includes a piston cylinder 4-2 and a piston 4-4 in the piston cylinder 4-2, and the piston cylinder 4-2 inside the piston 4-4 is provided with an inner air hole 4- 1. Make the piston cylinder 4-2 inside the piston 4-4 communicate with the inner cavity of the float housing 4, and the piston cylinder 4-2 outside the piston 4-4 or the float housing 4 is provided with an outer air hole 4-5, Make the piston cylinder 4-2 outside the piston 4-4 communicate with the space outside the float housing 4. A counterweight 10 is preferably provided at the inner bottom of the floating ball housing 4, so that the stability of the float...

Embodiment 2

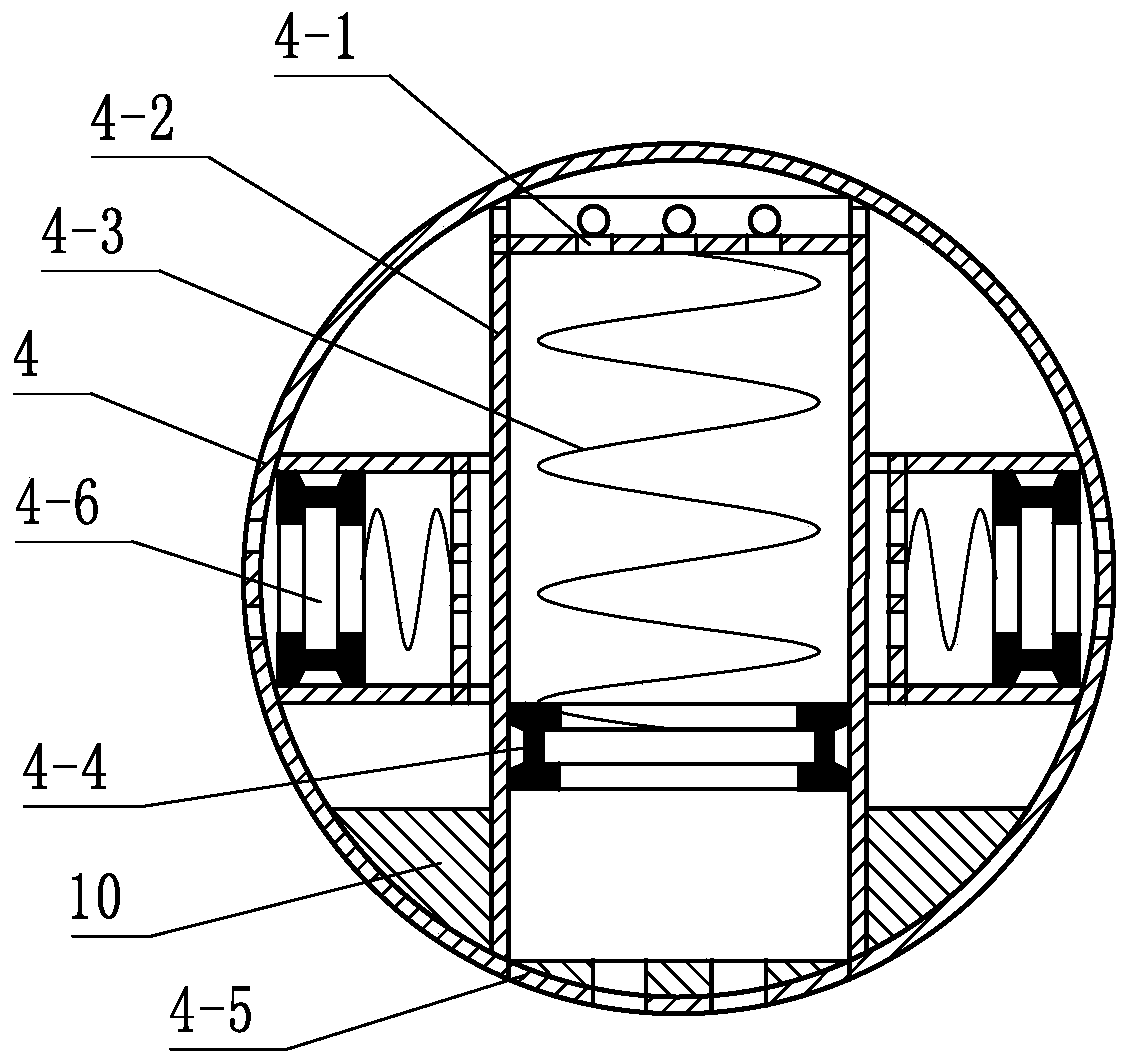

[0033] Embodiment 2: refer to image 3 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of Embodiment 2 is that several floating ball housings 4 outside the piston cylinder 4-2 are provided with several Around the auxiliary piston mechanism 4-6 outside the piston cylinder 4-2, the auxiliary piston mechanism 4-6 includes the inner air hole inside the piston cylinder, the piston, and the outer air hole 4-5 on the outer side of the piston. return spring.

Embodiment 3

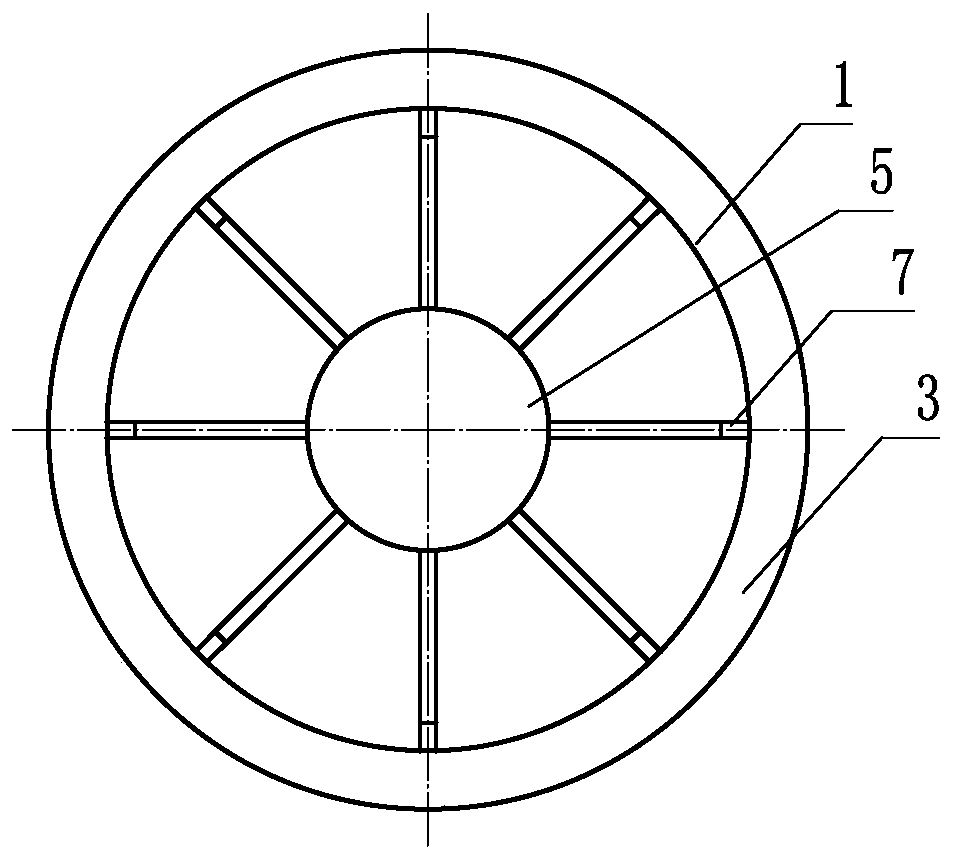

[0034] Embodiment 3: refer to Figure 4 , is a schematic structural view of Embodiment 3 of the present invention. Compared with the previous embodiments, the difference of this embodiment is that the rib 7 is a plurality of bends on the wall of the body of the floating ball outer barrel 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com