Gas-material-shared reversing valve for double-hearth vertical kiln

A double-chamber shaft kiln and two-way valve technology, applied in valve details, multi-port valves, control valves, etc., can solve problems such as the overall force impact of refractory materials, improve the operation time, reduce the quantity and weight, and optimize the resistance. The effect of the force state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

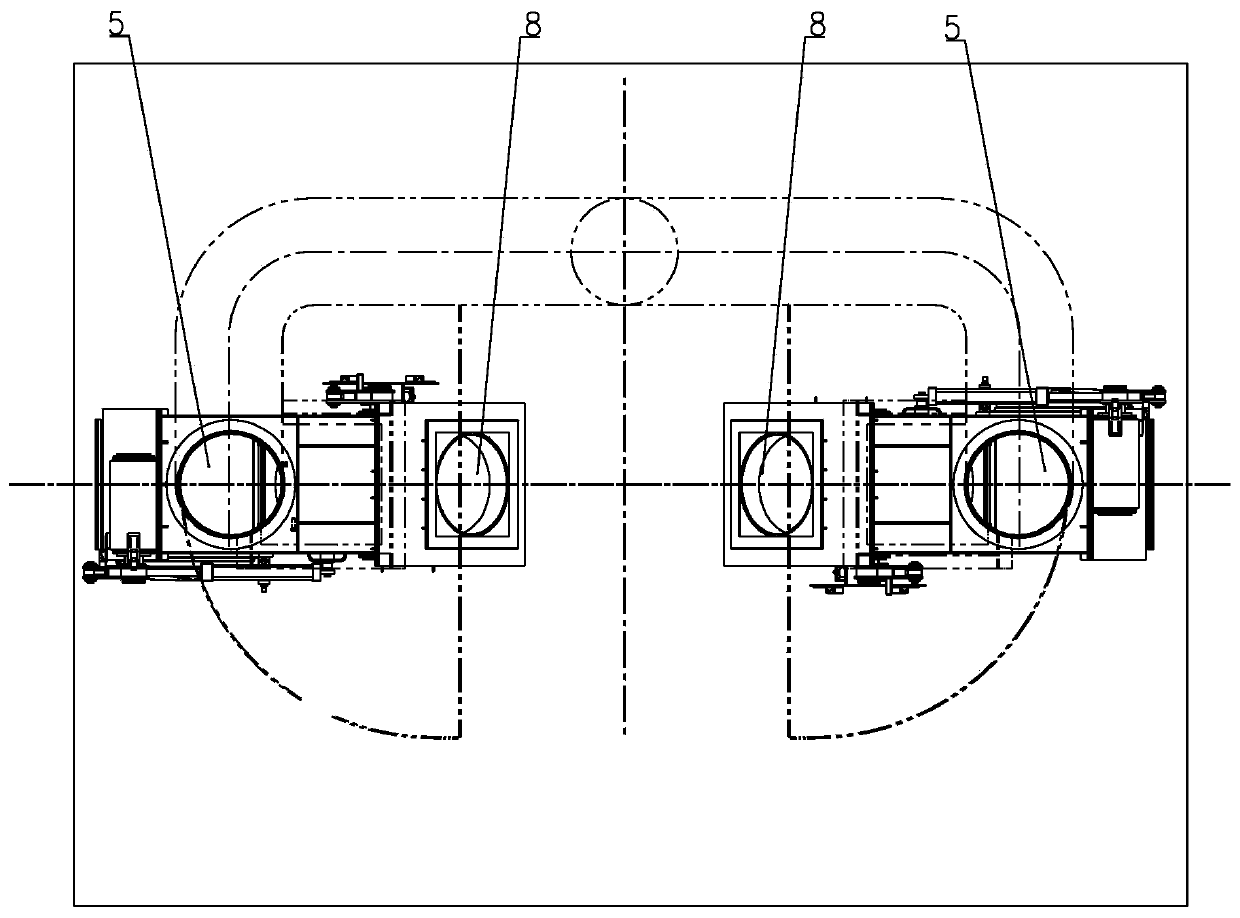

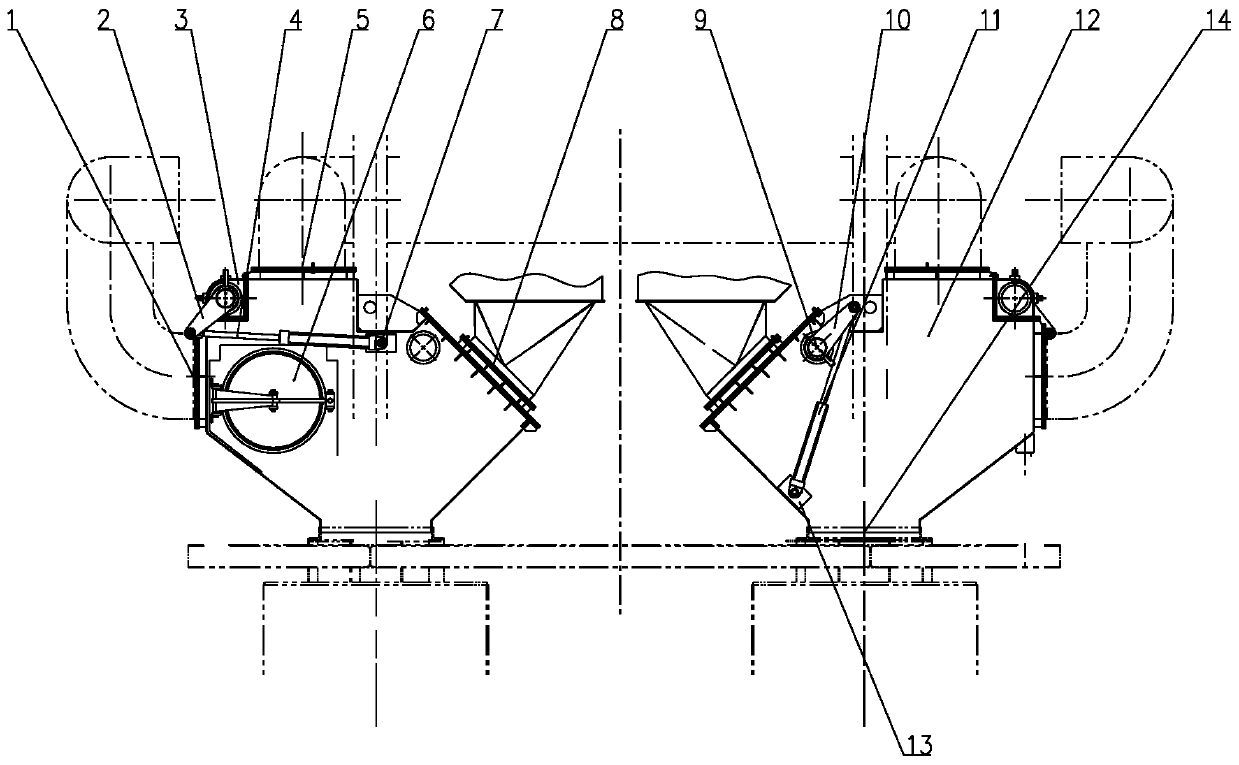

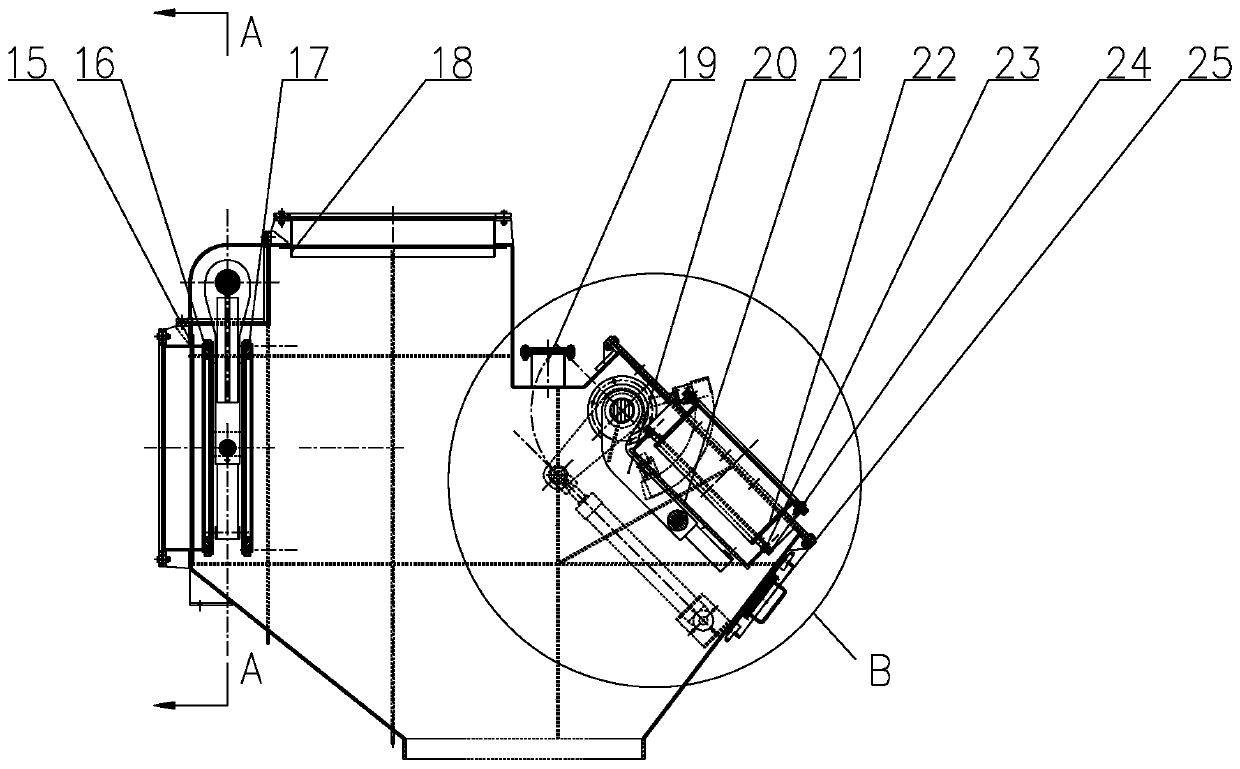

[0029] Such as Figure 1-Figure 5 As shown in the present invention, a gas-material common reversing valve for a double-chamber shaft kiln includes a valve body 12, a two-way valve mechanism and a one-way valve mechanism; the top side of the valve body 12 is provided with a waste gas outlet 5 Connected with the external exhaust gas pipeline, the side wall of the valve body 12 near the exhaust gas outlet 5 is provided with a combustion air inlet 1 connected to the external combustion air pipeline; the side of the valve body 12 opposite to the combustion air inlet 1 is provided with an inclined discharge port 8 Connected with the external feeding device, the bottom of the valve body 12 is provided with a discharge port 14 connected to the kiln chamber; the two-way valve mechanism is installed on the side close to the exhaust gas outlet 5 and the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com