Dyeing and moisturizing finishing process for thin polyester fabric

A fabric and polyester technology, applied in the field of functional finishing of textile fabrics, can solve the problems of increasing the moisturizing ability of fabrics, antibacterial performance, lack of moisturizing performance, etc., and achieve the effects of improving dye fastness, good antibacterial effect, and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

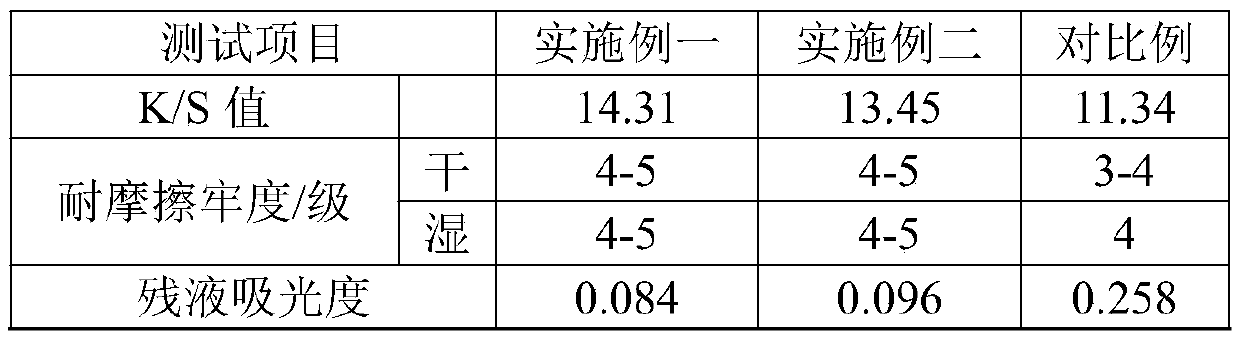

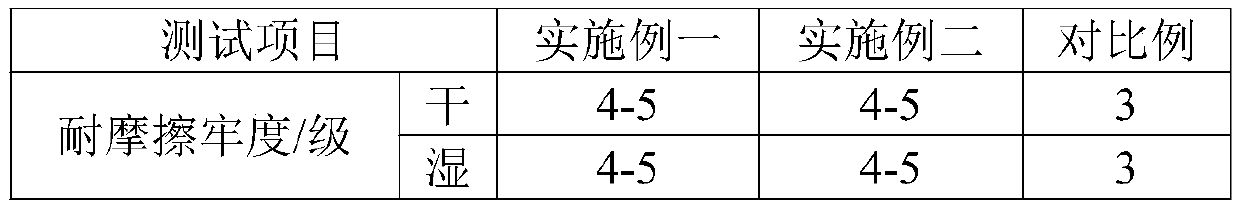

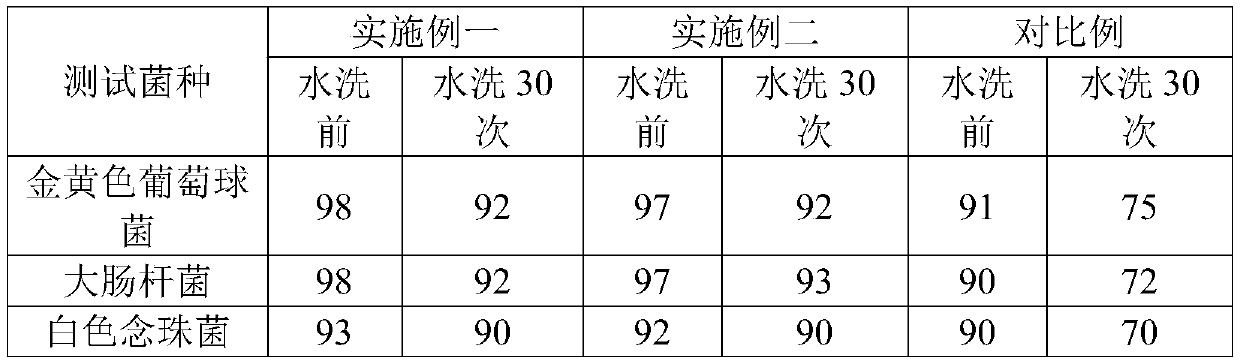

Embodiment 1

[0033] A kind of dyeing and moisturizing finishing process of thin polyester fabrics involved in the present embodiment comprises the following steps: step (1) pretreatment of polyester fabrics, step (2) dyeing of polyester fabrics, step (3) moisturizing finishing of polyester fabrics, step (4) ) drying and step (5) setting and anti-ultraviolet finishing.

[0034] In step (1) polyester fabric pretreatment, select 210T polyester taffeta fabric, under room temperature, add pretreatment liquid according to the liquor ratio of 1:10, the scouring agent of 1g / L is contained in the described pretreatment liquid, 4g / L caustic soda, 6g / L hydrogen peroxide, 5g / L stabilizer BS; after heating from room temperature to 60°C at a rate of 0.7°C / min, run for 8 minutes, and then increase the temperature to 85°C at a rate of 1°C / min. Run at constant temperature for 30 minutes, drain the liquid, wash with water at 60°C for 10 minutes, then pickle with acetic acid solution with a pH value of 5.5 a...

Embodiment 2

[0046] A kind of dyeing and moisturizing finishing process of thin polyester fabrics involved in the present embodiment comprises the following steps: step (1) pretreatment of polyester fabrics, step (2) dyeing of polyester fabrics, step (3) moisturizing finishing of polyester fabrics, step (4) ) drying and step (5) setting and anti-ultraviolet finishing.

[0047] In step (1) polyester fabric pretreatment, select 210T polyester taffeta fabric, under room temperature, add pretreatment liquid according to the bath ratio of 1:15, the scouring agent of 2g / L is contained in the described pretreatment liquid, 8g / L caustic soda, 10g / L hydrogen peroxide, 10g / L stabilizer BS; after heating from room temperature to 65°C at a rate of 1°C / min, run for 15 minutes, and then increase the temperature to 90°C at a rate of 2°C / min. Run at constant temperature for 40 minutes, drain the liquid, wash with water at 65°C for 15 minutes, then pickle with acetic acid solution with a pH value of 6 at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com