Cotton cleaning and casing device

A flower packing and cotton technology, applied in the equipment field of the textile industry, can solve the problems of residual impurities, affecting the carding effect of the carding machine, affecting the product quality, etc., to reduce impurities, improve the processability and improve the effect of carding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

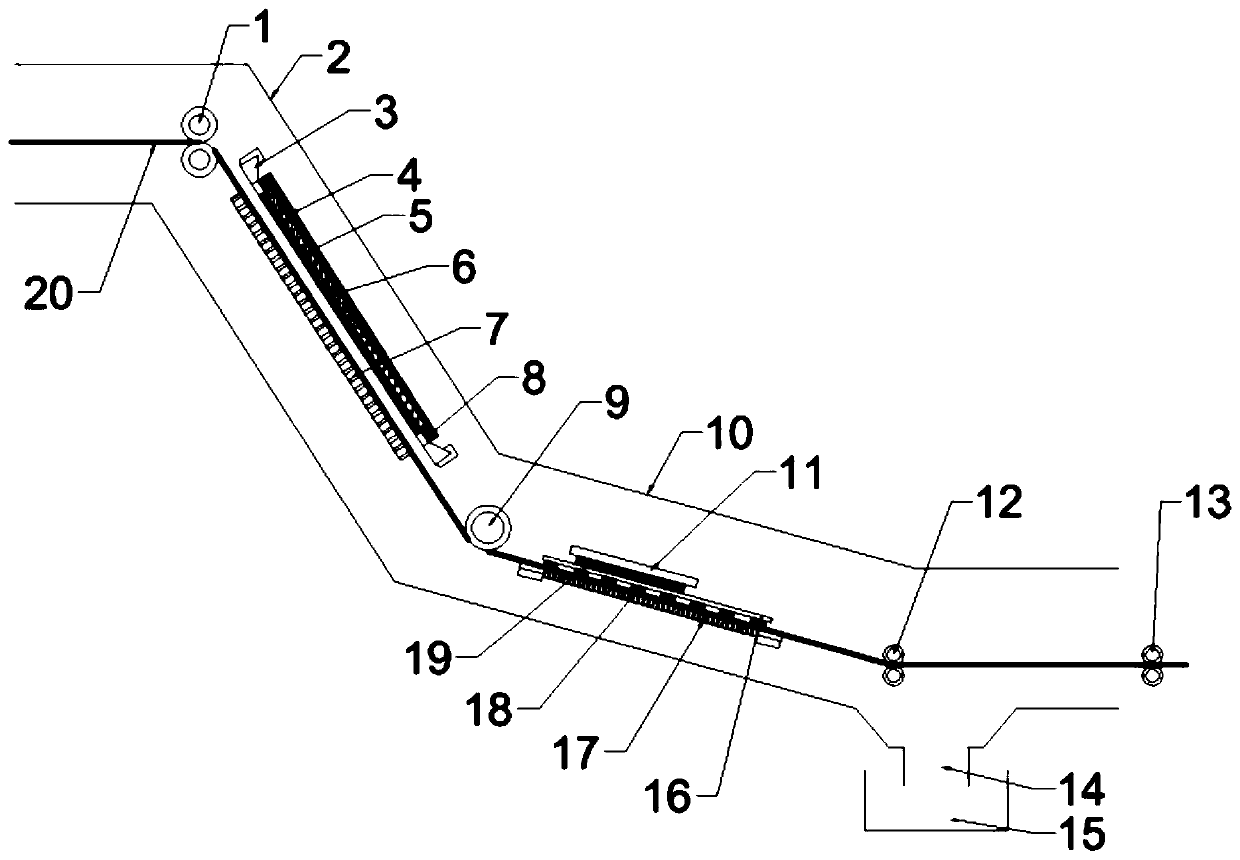

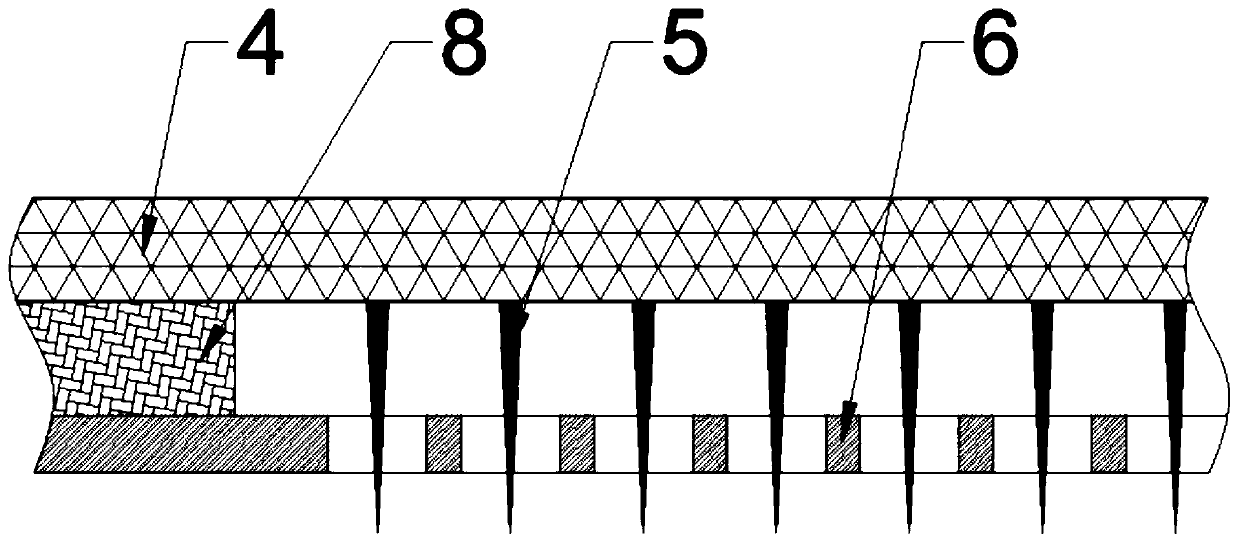

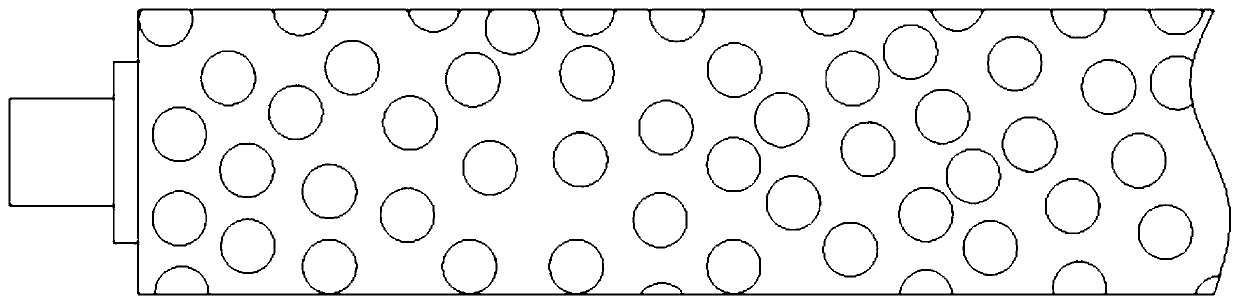

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0023] see Figure 1 ~ Figure 3 A schematic diagram of a preferred embodiment of a cotton cleaning and boxing device, in this embodiment, including a conduit assembly as a walkway for cotton rolls 20, and an impurity removal assembly and a roller assembly formed in the conduit assembly, wherein the conduit assembly Including the first conduit 2 and the second conduit 10, the first conduit 2 and the second conduit 10 are obliquely fixed, and are connected and fixed by welding between the first conduit 2 and the second conduit 10, the first conduit 2 The angle between the fixed and horizontal plane is 62°, and the angle between the second conduit 10 and the horizontal plane after being fixed is 30°. Wherein, the front end of the first conduit 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com