Cellulose/nano-inorganic particle composite pigment and its preparation method and application

A technology of nano-inorganic particles and composite pigments, which is applied in the field of dyeing pigments. It can solve the problems of poor compatibility between large-sized inorganic particles and plastic substrates, the decline in mechanical properties of plastic products, and poor coloring power of inorganic pigments to achieve durable and firm coloring. Ability, not easy to fall off, strong coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

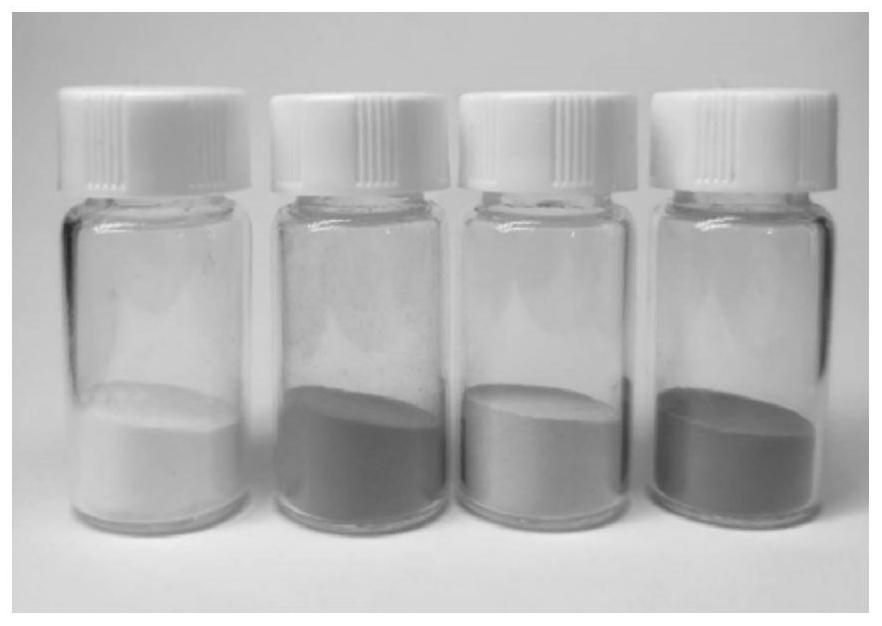

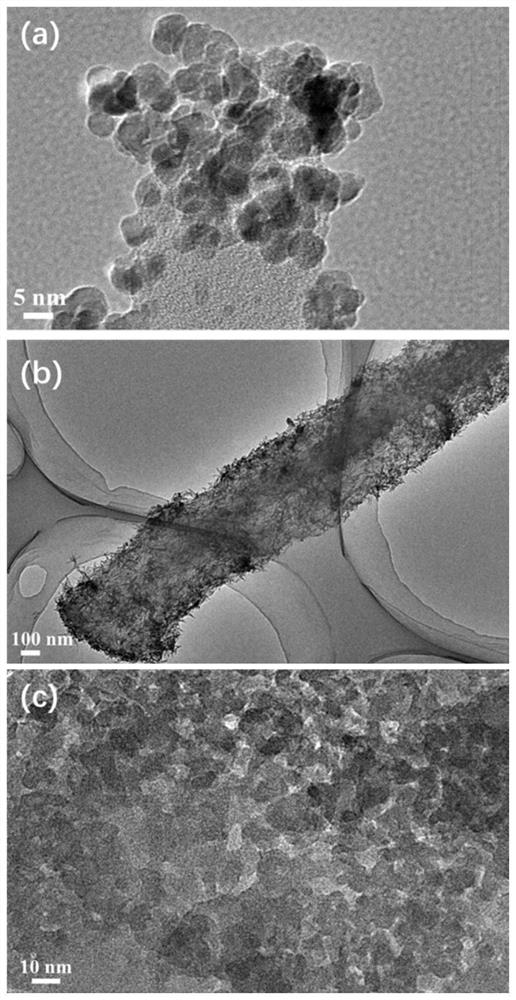

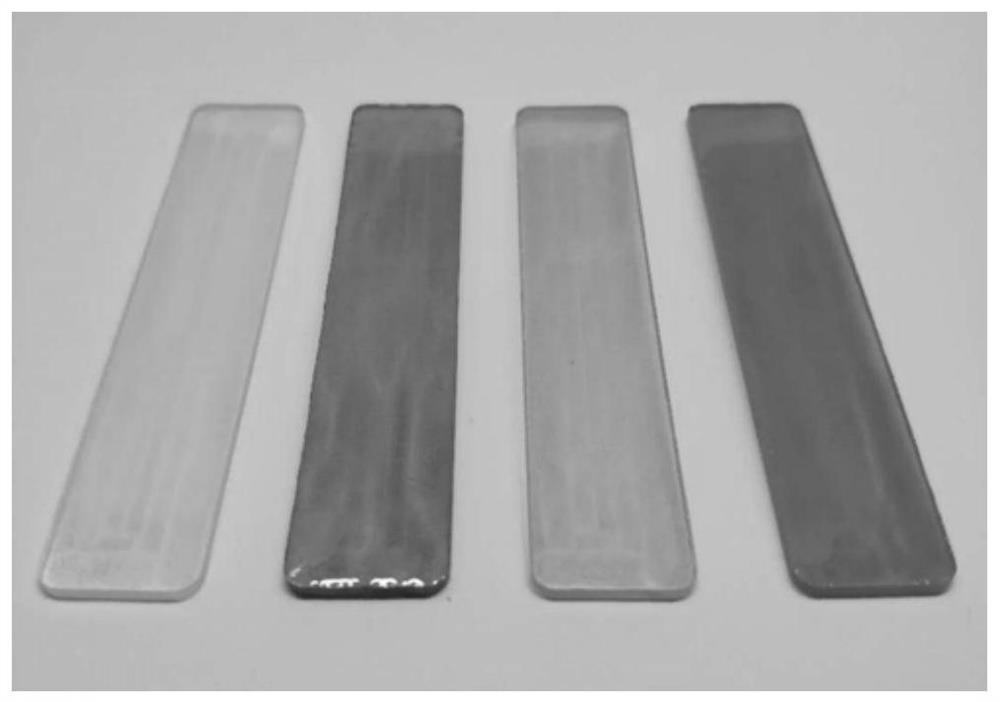

Embodiment 1

[0036] Add 0.4mol ferric chloride, 0.2mol ferrous sulfate and cellulose with 16 times the mass of iron to water to form a suspension. Then sodium hydroxide solution (1 mol / L) was added to adjust the pH value of the solution to 9-10, and stirred at 60° C. for 2 hours. Filter and dry to obtain red composite pigment cellulose / iron red.

[0037] Add 0.1mol ammonia water, 0.3mol ferric chloride and cellulose with 18 times the mass of iron to water to form a suspension. Stir at 95°C for 4 hours. Filter and dry to obtain yellow composite pigment cellulose / iron yellow.

[0038] First add 0.3mol potassium ferricyanide and cellulose into deionized water, add hydrochloric acid to adjust its pH value to 1-2, and obtain material A; then dissolve 0.4mol ferrous sulfate in deionized water, add hydrochloric acid to adjust the pH of the solution A value of 1-2 yielded material B. Wherein the mass of cellulose in material A is 25 times of the total mass of iron element in material A and mat...

Embodiment 2

[0044] Add 0.2mol ferric sulfate, 0.1mol ferrous chloride and cellulose with 18 times the mass of iron to water to form a suspension. Then add sodium hydroxide solution (2mol / L) to adjust the pH value to 11-12, and stir at 70°C for 3 hours. Filter and dry to obtain red pigment-cellulose / iron red.

[0045]Add 0.2mol ammonia water, 0.6mol iron sulfate and cellulose with 20 times the mass of iron element into the water. Stir at 80°C for 6 hours. Filter and dry to obtain yellow pigment-cellulose / iron yellow.

[0046] First add 0.6mol potassium ferricyanide and cellulose into deionized water, then add sulfuric acid to adjust the pH value to 1-2 to obtain material A; then dissolve 0.8mol ferrous sulfate in deionized water, add sulfuric acid to adjust the pH value of the solution For 1-2, material B was obtained. The mass of cellulose is 28 times of the total mass of iron element. Mix material A and material B, heat to 60°C and stir for 4 hours. Filter and dry to obtain blue pi...

Embodiment 3

[0049] Add 0.4mol ferric nitrate, 0.2mol ferrous nitrate and cellulose with 20 times the mass of iron element into water to form a suspension. Then potassium hydroxide solution (3 mol / L) was added to adjust the pH value to 9-10, and stirred at 80°C for 1 hour. Filtration and drying yielded red cellulose / iron red.

[0050] Dissolve 0.1mol ammonia water, 0.3mol ferric nitrate and cellulose with 22 times the mass of iron element into water. Stir at 95°C for 3 hours. Filtration and drying yielded yellow cellulose / iron yellow.

[0051] First add 0.15mol of sodium ferricyanide and cellulose into deionized water, then add hydrochloric acid to adjust the pH value of the solution to 1-2, and obtain material A; then dissolve 0.2mol of ferrous nitrate in deionized water, add hydrochloric acid to adjust the solution The pH value is 1-2, and material B is obtained. The mass of cellulose is 30 times of the total mass of iron element. Mix material A and material B, heat to 80°C and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com