Preparation method of emblic leafflower fruit polysaccharide

A technology of emblica and polysaccharides, which is applied in the field of preparation of polysaccharides from emblica, can solve the problems of high safety risks, complicated operation steps, and not widely used, and achieve the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

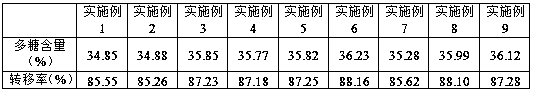

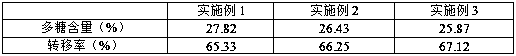

Examples

Embodiment 1

[0041] Take 10 g of emblica medicinal material with a particle size of 5 mesh, and extract it twice with 20 g of 90% ethanol at a temperature of 45 ° C, 5 hours each time, evaporate the solvent to obtain the medicinal residue, add 10 BV of distilled water to the medicinal residue, and extract 2 times at 80 ° C. Each time, 50 minutes each time, the water extract was concentrated to a liquid density of 0.5g / ml, and 90% ethanol was added until the alcohol concentration was 78%, and it was left to stand for 5 hours, centrifuged (3000 rpm, time 25 minutes), and the obtained precipitate was anhydrous Washed repeatedly with ethanol, spray dried to obtain 355.11 mg of solid.

Embodiment 2

[0043] Take 10g of emblica medicinal material with a particle size of 10 mesh, extract 3 times with 30g of 75% ethanol at a temperature of 55°C, each time for 3h, evaporate the solvent to obtain the medicinal residue, add 16BV distilled water to the medicinal residue, and extract 4 at 85°C Once, each time for 80 minutes, the water extract was concentrated to a liquid density of 2 g / ml, and 98% ethanol was added to reach an alcohol concentration of 82%, left to stand for 15 hours, centrifuged (3000 rpm, time 20 minutes), and the obtained precipitate was washed with absolute ethanol After repeated washing and spray drying, 354.21 mg of solid was obtained.

Embodiment 3

[0045] Take 10g of emblica medicinal material with a particle size of 20 mesh, extract 4 times with 10g of 70% ethanol at a temperature of 60°C, each time for 1h, evaporate the solvent to obtain medicinal residues, add 12BV of distilled water to the medicinal residues, and extract at 90°C for 3 Each time, 60 minutes each time, the water extract was concentrated to a liquid density of 1 g / ml, and 95% ethanol was added until the alcohol concentration was 80%, left to stand for 10 hours, centrifuged (3000 rpm, time 30 minutes), and the obtained precipitate was washed with absolute ethanol After repeated washing and drying under reduced pressure, 366.23 mg of solid was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com