A double-layer continuous pipe threading device and pipe threading method

A pipe threading device and coiled tubing technology, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large impact on the service life of coiled tubing, high manual labor intensity, and large space occupation, so as to reduce labor intensity , easy to operate, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

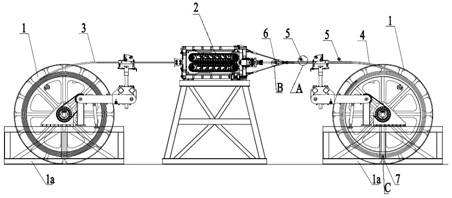

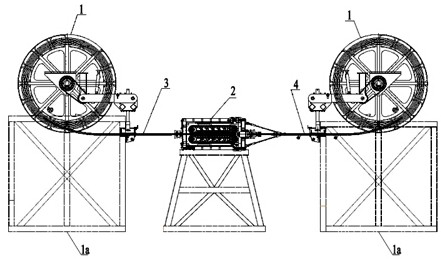

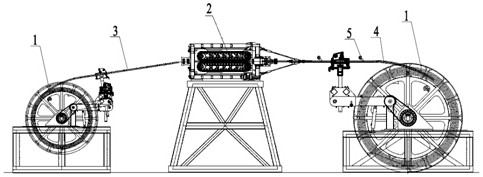

[0047] as attached figure 1 - As shown in 9, a double-layer coiled tubing threading device in this embodiment includes a roller skid 1, an injection head mechanism 2, a coiled tubing 1 3, a coiled tubing 2 4, a water injection device 5, a sealing assembly 6 and a cage 7; Skid 1 includes base 1a, roller 1b, mounting base 1c, power unit 1d, pipe arrangement 1e and depth counter 1f; injection head mechanism 2 includes base 2a, frame body 2b, guide device 2c, gooseneck 2d and push device 2e, the guiding device 2c includes a splint 2c1 and a roller 2c2, the pushing device 2e includes a rotating shaft group 2e1, a chain 2e2 and a clamping block 2f, and a waist-shaped hole 7a is opened on the cage 7; the continuous tube-3 extends through the injection head mechanism 2 After the coiled tubing 1 and the injection head mechanism 2 are installed in place, the coiled tubing 1 3 slides forward under the push of the injection head mechanism 2 to drive the coiled tubing 2. The drum 1b of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com