An effective recovery process of associated niobium and tantalum in rare metal ores

A rare metal, niobium and tantalum technology, applied in the field of effective recovery process of rare metal ore associated niobium and tantalum, can solve the problems of poor production process stability, low recovery rate of niobium and tantalum, large number of equipment, etc. The effect of high recovery index and single process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

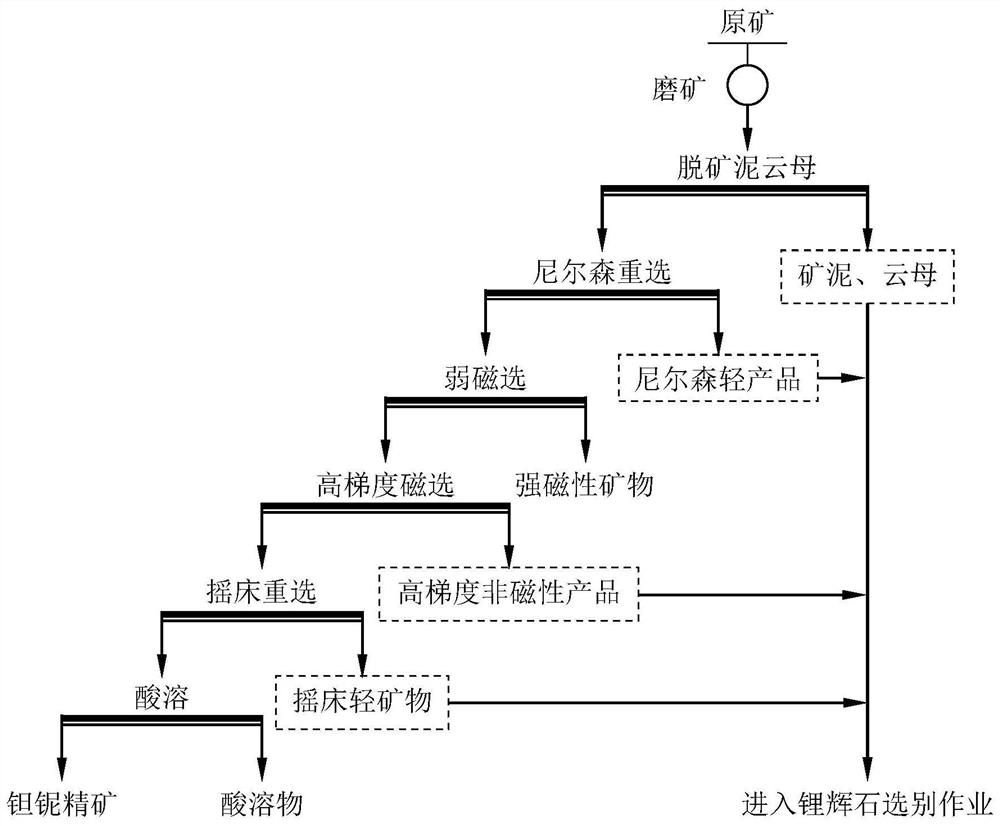

[0022] see figure 1 , a rare metal spodumene mine in Sichuan is associated with niobium and tantalum, and Nb in the original ore 2 o 5 The content is 0.0087%, Ta 2 o 5 The content is 0.0052%, Li 2 O content 1.55%.

[0023] The recovery process of the rare metal spodumene ore associated with niobium and tantalum minerals is:

[0024] 1) Grinding: The raw ore is crushed and ground to -0.074mm, accounting for 35.4%, and the grinding concentration is 55%.

[0025] 2) Desliming and mica removal operations: put the ore pulp after grinding in step 1) into a spiral chute for sorting to obtain slime mica products and products from which slime mica has been removed.

[0026] 3) Nelson concentrator re-separation: the products obtained by step 2) spiral chute separation to remove slime and mica are put into Nelson concentrator for re-separation to obtain Nelson niobium tantalum heavy mineral products and light products.

[0027] 4) Weak magnetic separation: The niobium and tantalum...

Embodiment 2

[0034] A rare metal spodumene mine in Sichuan is associated with niobium and tantalum, and the Nb in the original ore 2 o 5 The content is 0.0095%, Ta 2 o 5 The content is 0.0047%, Li 2 O content 1.43%.

[0035] The recovery process of the rare metal spodumene ore associated with niobium and tantalum minerals is:

[0036] 1) Grinding: The raw ore is crushed and ground to -0.074mm, accounting for 45.1%, and the grinding concentration is 60%.

[0037] 2) Desliming and mica removal operations: put the ore pulp after grinding in step 1) into a spiral chute for sorting to obtain slime mica products and products from which slime mica has been removed.

[0038] 3) Nelson concentrator re-separation: the products obtained by step 2) spiral chute separation to remove slime and mica are put into Nelson concentrator for re-separation to obtain Nelson niobium tantalum heavy mineral products and light products.

[0039] 4) Weak magnetic separation: The niobium and tantalum heavy miner...

Embodiment 3

[0046] A rare metal spodumene mine in Sichuan is associated with niobium and tantalum, and the Nb in the original ore 2 o 5 The content is 0.0102%, Ta 2 o 5 The content is 0.0058%, Li 2 O content 1.34%.

[0047] The recovery process of the rare metal spodumene ore associated with niobium and tantalum minerals is:

[0048] 1) Grinding: The raw ore is crushed and ground to -0.074mm, accounting for 54.8%, and the grinding concentration is 65%.

[0049] 2) Desliming and mica removal operations: put the ore pulp after grinding in step 1) into a spiral chute for sorting to obtain slime mica products and products from which slime mica has been removed.

[0050] 3) Nelson concentrator re-separation: the products obtained by step 2) spiral chute separation to remove slime and mica are put into Nelson concentrator for re-separation to obtain Nelson niobium tantalum heavy mineral products and light products.

[0051] 4) Weak magnetic separation: The niobium and tantalum heavy miner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com