Defatting method for processing eel foods

A technology for removing oil and eel, applied in the direction of food science, can solve the problems of affecting the taste of food, difficult to achieve the effect of oil removal, disadvantage, etc., to improve the efficiency of piercing, control the effect of piercing, and facilitate piercing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

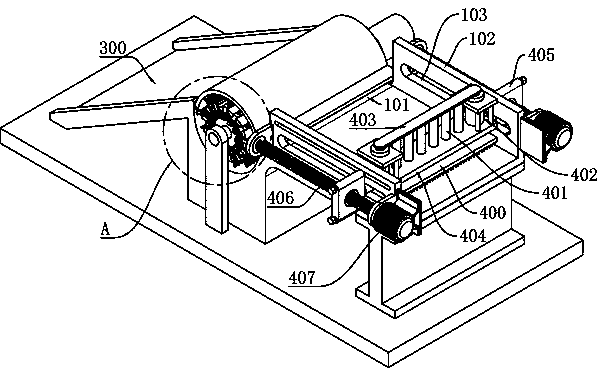

Image

Examples

Embodiment 1

[0029] Preparation stage: Prepare 10 eels that have been temporarily raised in water for more than 24 hours. After freezing, dissect, remove the head, open the back, remove the bones, remove the internal organs, mark the meat surface, and wash.

[0030] The cleaned eels are grilled on the leather surface, and the eels are arranged in a single layer, with the side to be grilled facing up, and the eels are passed through the grilling flame at a predetermined speed without pausing to complete the grilling from the top to the bottom of the oven cavity. The extent is limited to the extent that the grilled leather surface does not have burnt spots.

[0031] Specifically, when the leather surface is grilled, the temperature of the oven cavity is 120° C., and the predetermined speed is set so that the time for the eel to pass through the oven cavity is 5 minutes. During the grilling process on the leather surface, part of the overflowing fat drips down and drains.

[0032] After fini...

Embodiment 2

[0042] Preparation stage: Prepare 10 eels that have been temporarily raised in water for more than 24 hours. After freezing, dissect, remove the head, open the back, remove the bones, remove the internal organs, wash, and mark the meat surface.

[0043] The cleaned eels are grilled on the leather surface, and the eels are arranged in a single layer, with the side to be grilled facing up, and the eels are passed through the grilling flame at a predetermined speed without pausing to complete the grilling from the top to the bottom of the oven cavity. The extent is limited to the extent that the grilled leather surface does not have burnt spots.

[0044] Specifically, when the leather surface is grilled, the temperature of the oven cavity is 180° C., and the predetermined speed is set so that the time for the eel to pass through the oven cavity is 1 minute. During the grilling process on the leather surface, part of the overflowing fat drips down and drains.

[0045] After finis...

Embodiment 3

[0055]Preparation stage: Prepare 10 eels that have been temporarily raised in water for more than 24 hours. After freezing, dissect the eels, remove the head, open the back, remove the bones, remove the internal organs, and wash.

[0056] The cleaned eels are grilled on the leather surface, and the eels are arranged in a single layer, with the side to be grilled facing up, and the eels are passed through the grilling flame at a predetermined speed without pausing to complete the grilling from the top to the bottom of the oven cavity. The extent is limited to the extent that the grilled leather surface does not have burnt spots.

[0057] Specifically, when the leather surface is grilled, the temperature of the oven cavity is 150° C., and the predetermined speed is set so that the time for the eel to pass through the oven cavity is 3 minutes. During the grilling process on the leather surface, part of the overflowing fat drips down and drains.

[0058] After finishing the grill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com