A method and system for measuring the refractive index of particles using the polarization difference of scattered light

A technology of polarization difference and scattered light, applied in measurement devices, particle and sedimentation analysis, particle size analysis, etc., can solve the problem of particle size distribution error, difficult to determine the accurate refractive index of particles, etc., and achieve the effect of accurate sample particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

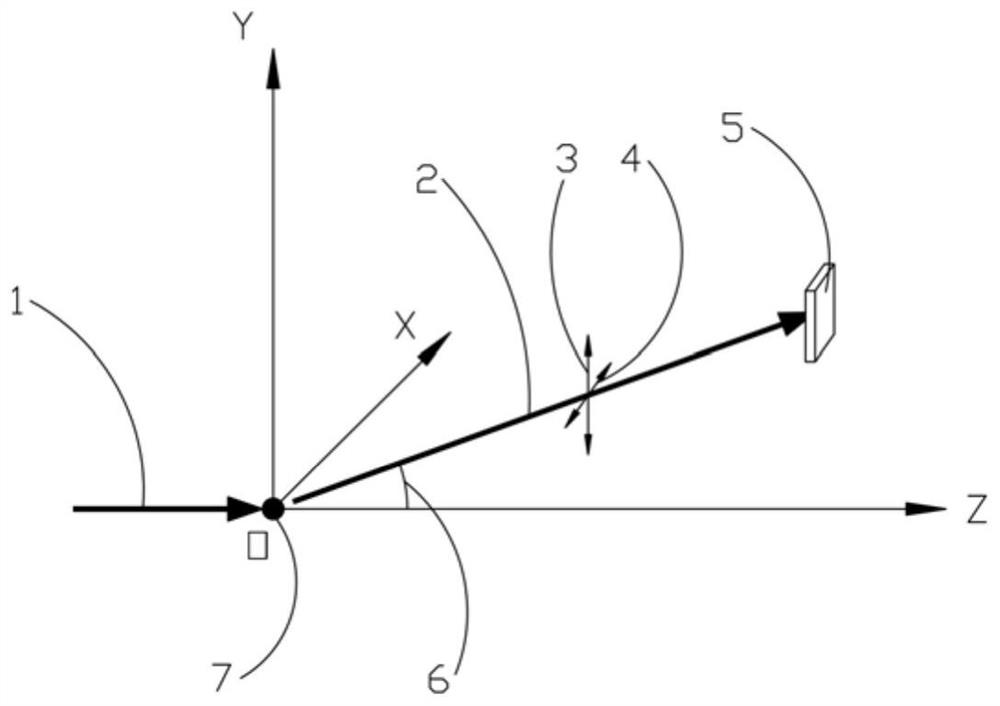

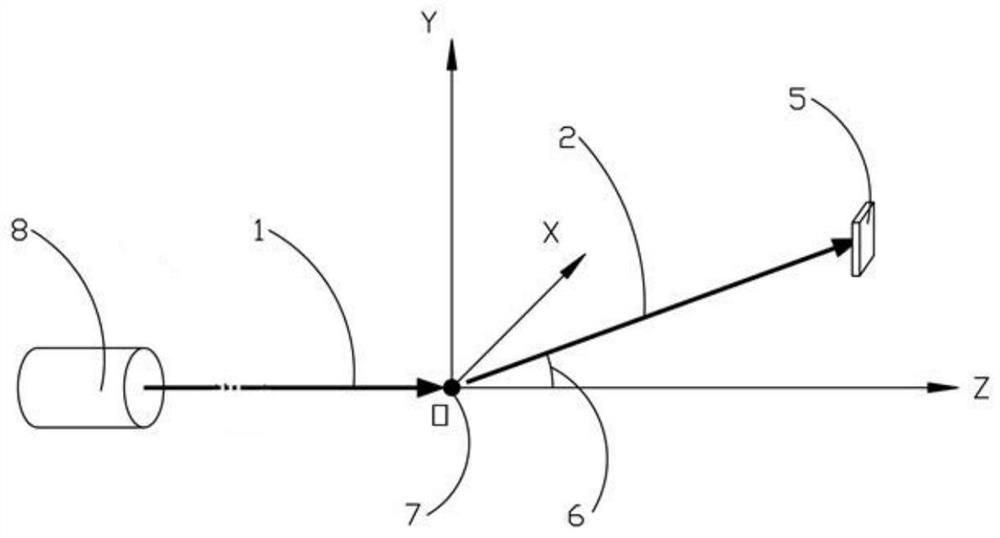

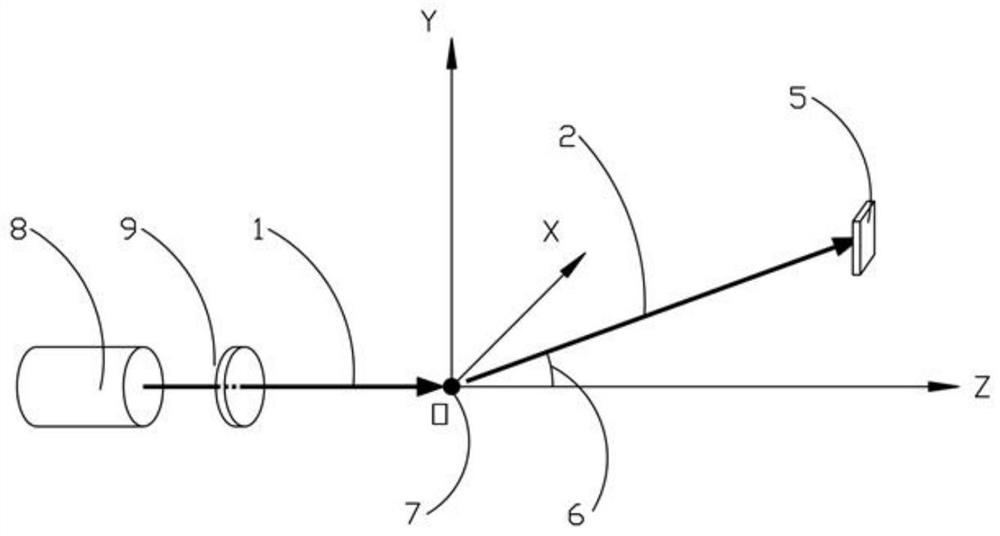

[0023] A method for measuring the refractive index of particles using the difference in polarization of scattered light, comprising the steps of:

[0024] S1, when the light wave is irradiated to the particle located at the coordinate origin O along the Z axis, the light scattered by the particle is received by the detector located on the XOZ plane. The detector is an array composed of multiple independent detection units, all units are located in the XOZ plane, and each unit corresponds to a different scattering angle. Let the total number of detection units be k. When the illumination light is linearly polarized light and the polarization direction is parallel to the Y axis, the polarization directions of the scattered light received by each detection unit are all perpendicular to the XOZ plane, that is, the scattering surface. Sorting from the inside to the outside according to the size of the scattering angle, record the light energy received by each detection unit as E ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com