A wet ultrasonic vibrating screen

An ultrasonic vibration and wet technology, applied in the fields of sieve, solid separation, chemical instruments and methods, etc., can solve the problems of fine particle size of grinding products, insufficient screening efficiency and unsatisfactory screening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

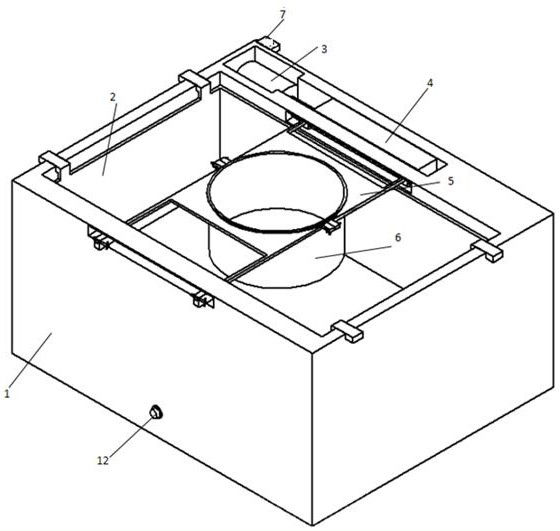

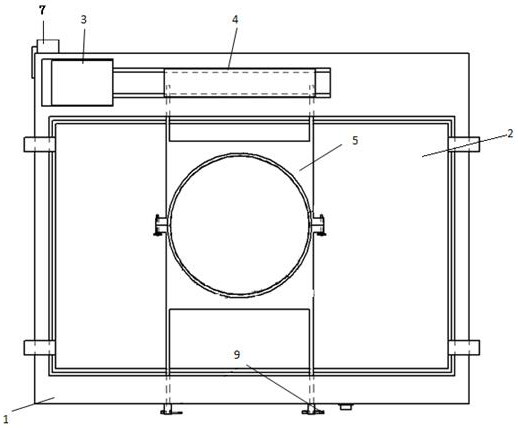

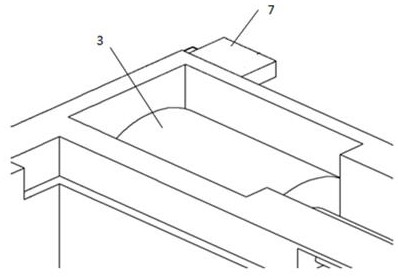

[0036] A wet ultrasonic vibrating screen, such as figure 1 , 2. Bolt 9, ultrasonic generator 10, ultrasonic generator controller 12, slider 17, hook 19; base 1 is a two-layer structure, the upper layer of base 1 is an unsealed box, and the inside of the upper box of base 1 is Stainless steel basin, hanging basin 2 is installed in the stainless steel basin of the upper box of the machine base 1, and four hooks 19 are arranged on the hanging basin 2, which are symmetrically arranged on opposite sides of the hanging basin 2, and the hanging basin 2 passes through four hanging basins. The hook 19 is hung on the opposite side wall of the machine base 1, and the opposite side wall of the machine base 1 has a card slot 20 matched with the hook 19. The hook 19 is firmly placed in the card slot 20, and the lower layer of the machine base 1 As a closed structure, the ultrasonic generator 10 is arranged in the closed structure of the lower layer of the machine base 1, and is close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com