Automatic cloth hanging device

A kind of transmission device and automatic technology, which is applied in the direction of textiles and papermaking, textile processing machine accessories, textile materials processing, etc., can solve the problems of heavy workload, long turnover period, dead wrinkles, etc., and achieve reduced production costs and continuous production capacity Strong, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

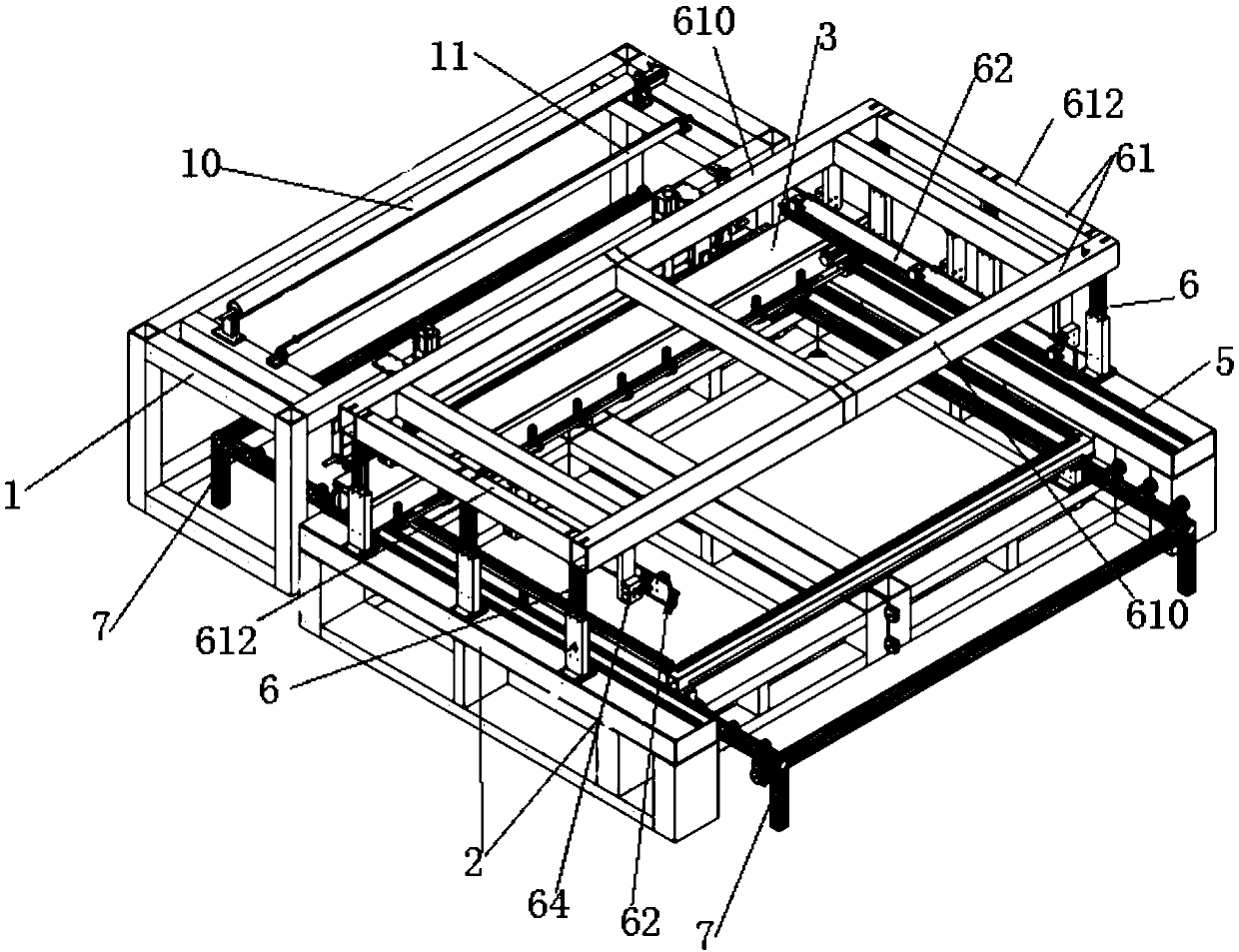

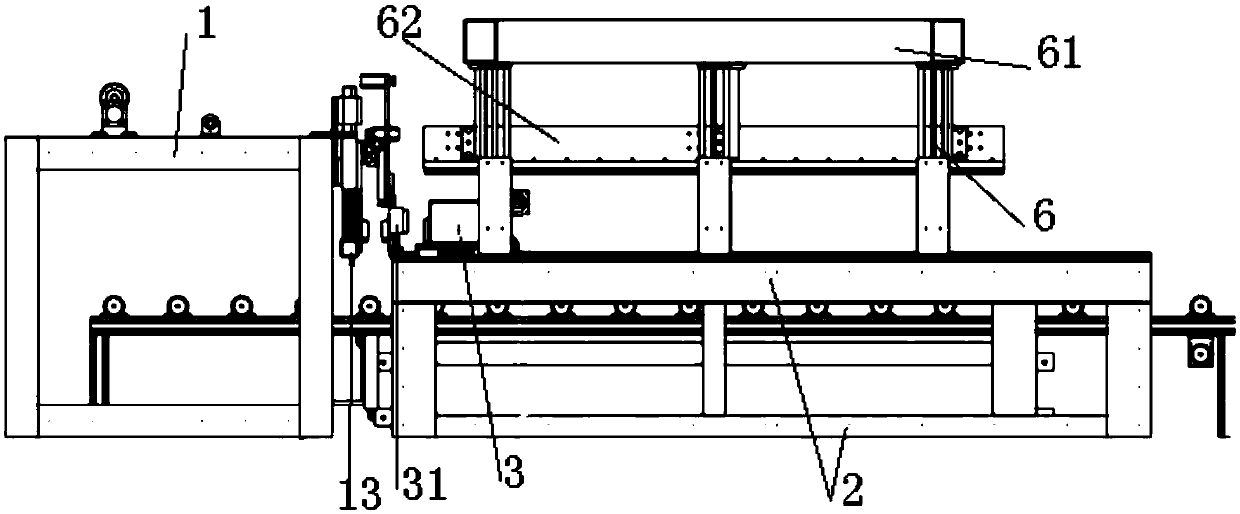

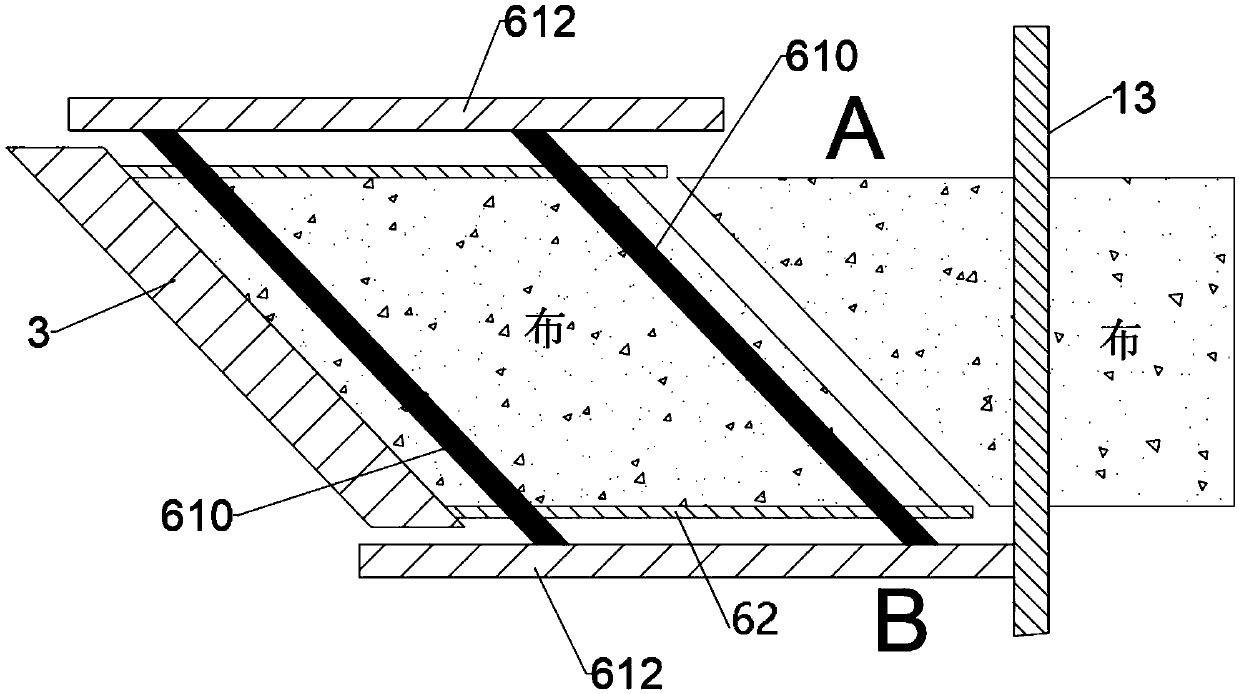

[0024] An automatic cloth hanging device, comprising a first base 1 and a second base 2; the first base 1 is provided with a first roller 10 and a second roller 11 parallel to each other, and the first base 1 is close to the first One side of the second base 2 is provided with a hanging cloth rack 13, and the hanging cloth rack 13 is parallel to the first roller 10;

[0025] One end of the second base 2 close to the first base 1 is provided with a gantry 3, the gantry 3 is parallel to the hanging cloth rack 13, and the X-axis hanging cloth rack 31 is arranged on the gantry 3;

[0026] The gantry 3 is connected to the second base 2 through a slide rail 5, and the guide rail 5 is perpendicular to the first drum 10. The gantry 3 and the second base 2 are also connected with a transmission device, and the transmission The device makes the gantry 3 slide along the guide rail 5;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com