Method for continuously preparing pre-oxidized felt

A technology for pre-oxygen felt and raw materials, which is applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., and can solve the problems of poor performance of polyacrylonitrile pre-oxygen felt, inability to continuously prepare polyacrylonitrile, and easy to catch fire. , to ensure the stable operation of the process, improve the penetration of hot air, and reduce the possibility of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Selected raw materials: width 2.2m, thickness 15mm, length 50m, density 0.13g / cm 3 ;

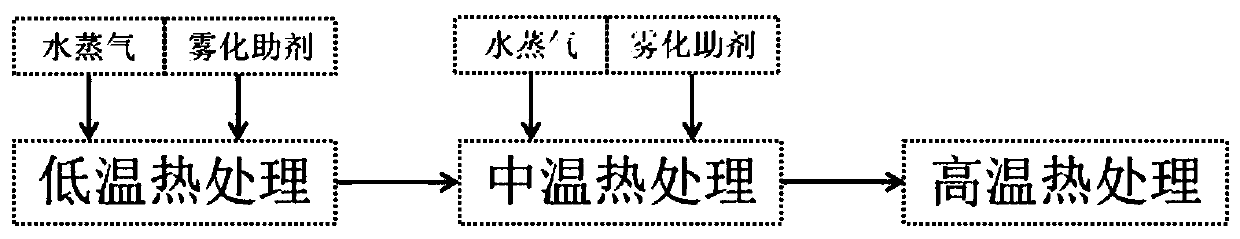

[0029] (1) The raw materials are conveyed into the low-temperature section furnace by means of mesh belt laying conveyance, the temperature gradient is 190-198°C; the hot air circulation volume is 3500m 3 / h, steam flow 400m 3 / h, atomization aid flow rate 0.6m 3 / h, the angle between the upper and lower air deflectors and the raw material is 45°, and the reaction time is 150 minutes;

[0030] (2) The raw materials are conveyed into the furnace in the middle temperature section by means of mesh belt tiled conveyance, with a temperature gradient of 208-215°C; hot air circulation volume of 5000m 3 / h, steam flow 600m 3 / h, atomization aid flow rate 1.5m 3 / h, the angle between the upper and lower air deflectors and the raw material is 45°; the reaction time is 240min;

[0031] (3) The raw materials are transported into the furnace in the middle temperature section by means of mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com