Filling foaming potting silicon rubber for new energy power battery, preparation method and application

A power battery and foamed silica gel technology, which is applied in the field of new energy power batteries, can solve problems such as inability to fill, and achieve the effect of excellent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

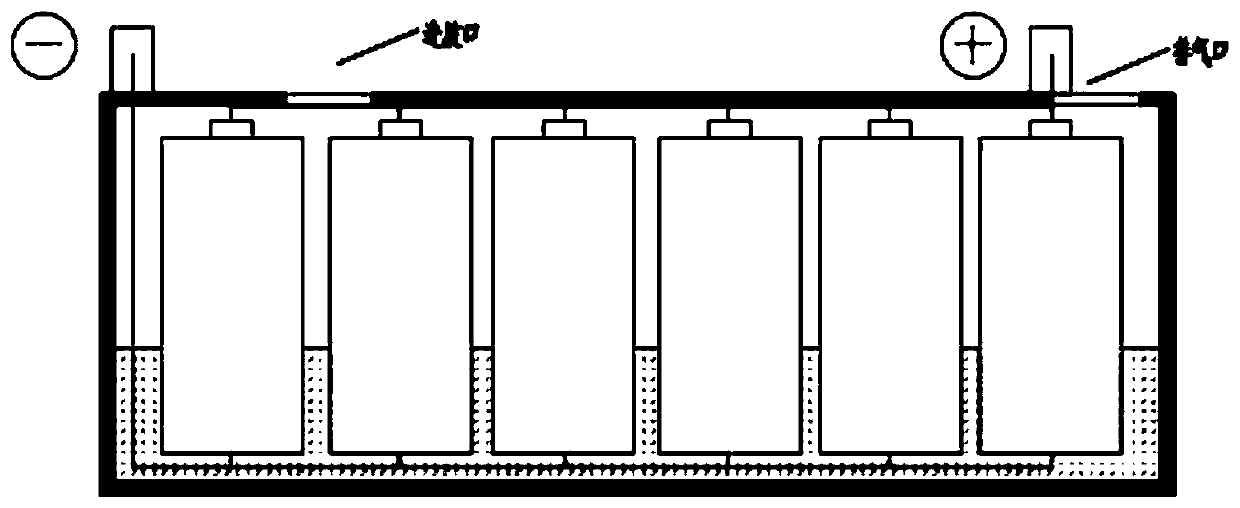

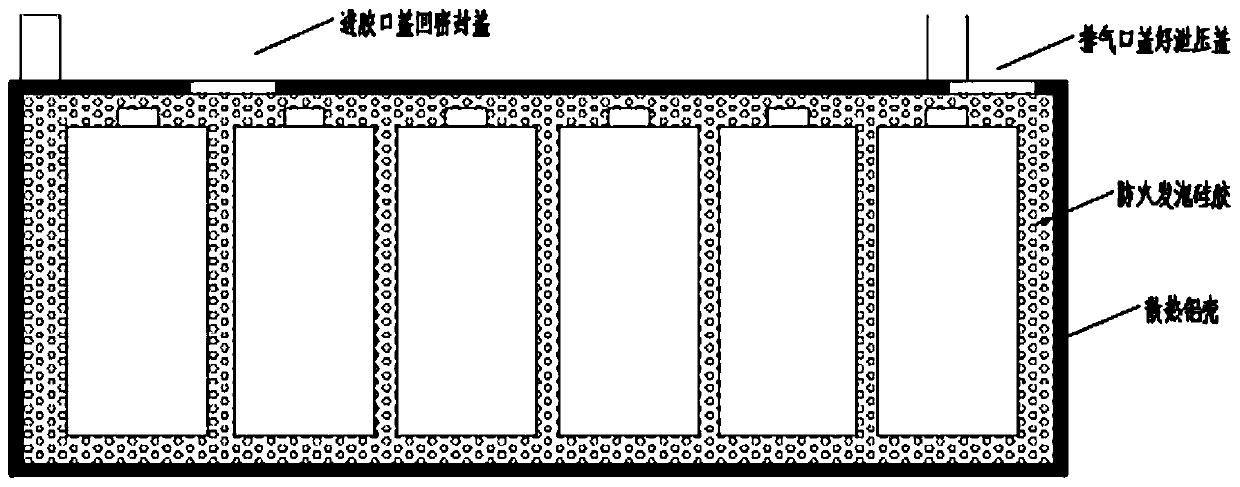

Image

Examples

Embodiment 1

[0059] Taking a filling foam potting silicone formula for new energy power batteries as an example, 35% mass fraction of 20000cps vinyl silicone oil, 5% mass fraction of 20000cps a,w-dihydroxypolydimethylsilane Oxane, stir and mix for 30-50min to obtain foamed silica gel-based glue; then mix 5% aluminum hydroxide, 26.57% mass fraction of nitrogen-phosphorus flame retardant powder, 15% mass fraction of antimony hydroxide, and stir and mix for 30 After -50min, 0.7% mass fraction of hexadecyltrimethoxysilane was added to treat the filler to obtain a flame-retardant foamed silica gel base material;

[0060] Component A: Take 500 grams of flame-retardant foamed silica gel base material, add 62.5 grams of 1.6% hydrogen-containing silicone oil, 0.9 grams of acetylene cyclohexanol, and 0.75 grams of black dyed filler; obtain a flame-retardant foam Bubble silica gel component A;

[0061] Component B: Take 500 grams of flame-retardant foamed silica gel base material, and add 3 grams of p...

Embodiment 2

[0065] Taking a formula for filling, foaming and encapsulating silicone for new energy power batteries as an example, 30% by mass fraction of 20,000cps vinyl silicone oil, 10% by mass fraction of 20,000cps a,w-dihydroxypolydimethylsiloxane , after stirring and mixing for 30-50min to obtain foamed silica gel-based glue; then 5% mass fraction of aluminum hydroxide, 26.57% mass fraction of nitrogen-phosphorus flame-retardant powder, 15% mass fraction of antimony hydroxide, stirring and mixing for 30-50min Finally, 0.7% mass fraction of cetyltrimethoxysilane is added to treat the filler to obtain a flame-retardant foamed silica gel base material;

[0066] Component A: Take 500 grams of flame-retardant foamed silica gel base material, add 62.5 grams of 1.6% hydrogen-containing silicone oil, 0.9 grams of acetylene cyclohexanol, and 0.75 grams of black dyed filler; obtain flame-retardant foamed silica gel group A Minute;

[0067] Component B: Take 500 grams of flame-retardant foamed...

Embodiment 3

[0072] Mix 25% of 20000cps vinyl silicone oil and 15% of 20000cps a,w-dihydroxy polydimethylsiloxane for 30-50 minutes to obtain foamed silica gel; then mix 5% of aluminum hydroxide, 26.57 % nitrogen phosphorus flame retardant powder, 15% antimony hydroxide, stirring and mixing for 30-50 minutes, and then adding 0.7% hexadecyltrimethoxysilane to treat the filler to obtain a flame retardant foamed silica gel base material.

[0073] Component A: Take 1000 grams of flame-retardant foamed silica gel base material, add 125 grams of 1.6% hydrogen-containing silicone oil, 1.8 grams of acetylene cyclohexanol by mass fraction, and 1.5 grams of black dyed filler; obtain flame-retardant foamed silica gel group A point.

[0074] Component B: Take 1000 grams of flame-retardant foamed silica gel base material, and add 6 grams of platinum catalyst (5000 ppm). Obtain the B component of flame-retardant foamed silica gel.

[0075] The performance of A and B after mixing evenly and curing is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com