Polypropylene composite material and preparation method and application thereof

A composite material and polypropylene-based technology, which is applied in the field of polypropylene-based composite materials and their preparation, can solve the problems of difficult power-on temperature rise and poor flame-retardant effect, and achieve the effects of reducing thermal oxygen degradation, high thermal conductivity, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

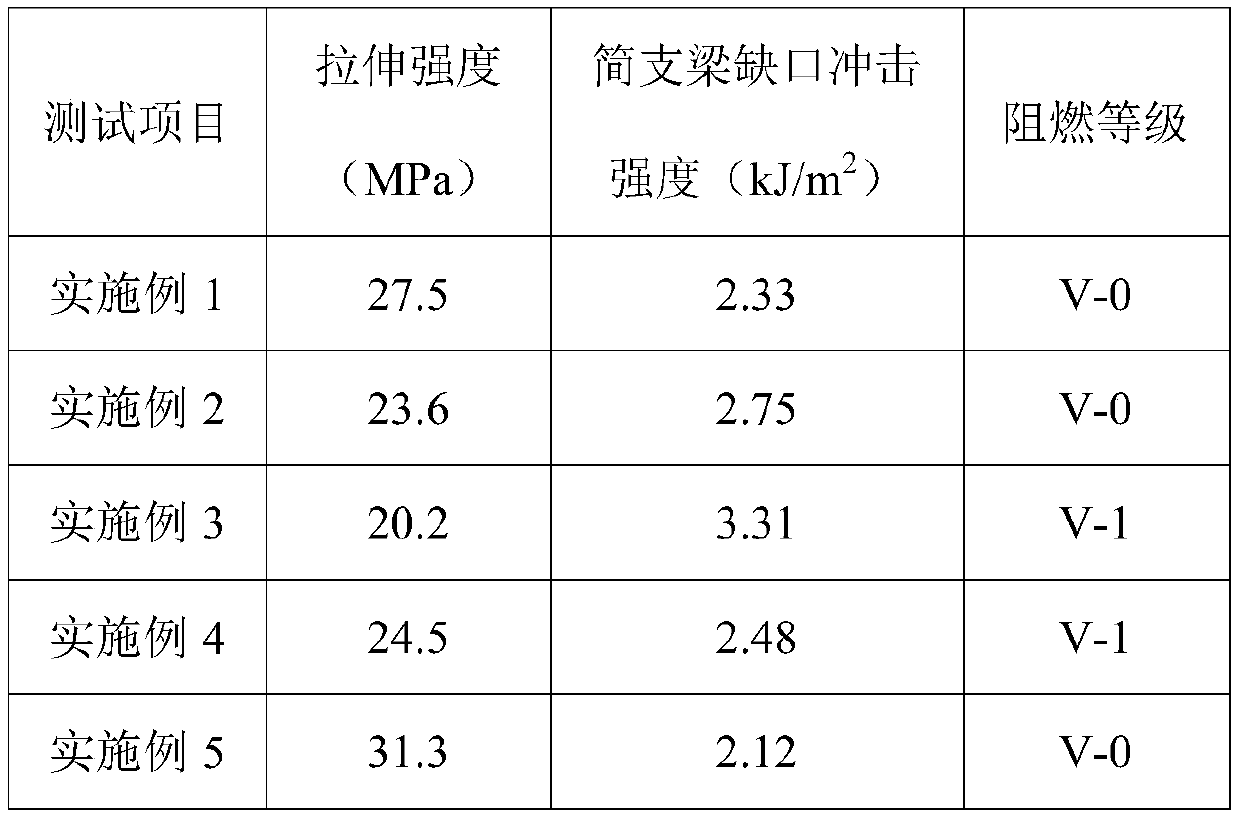

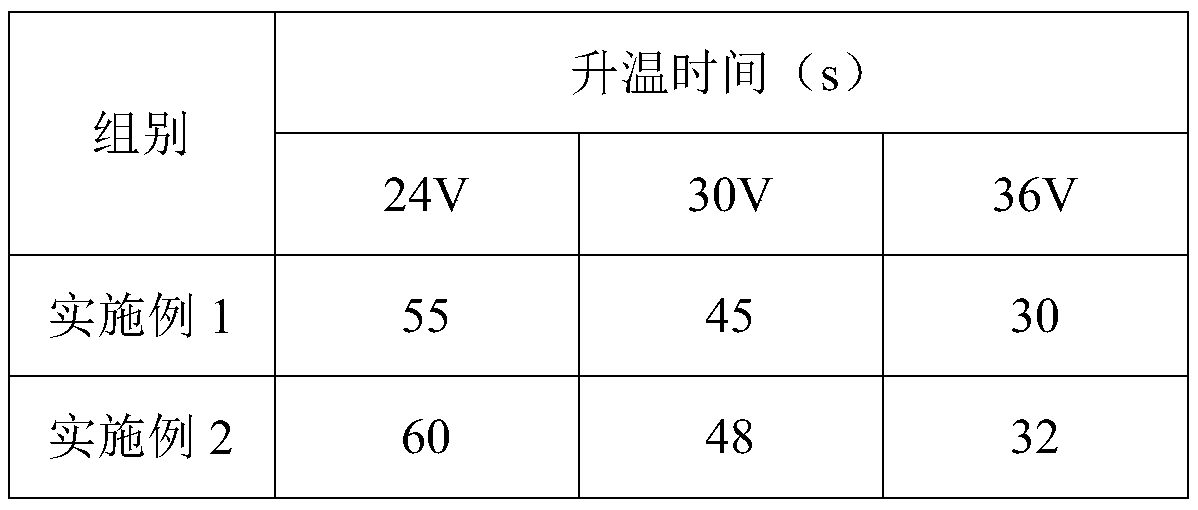

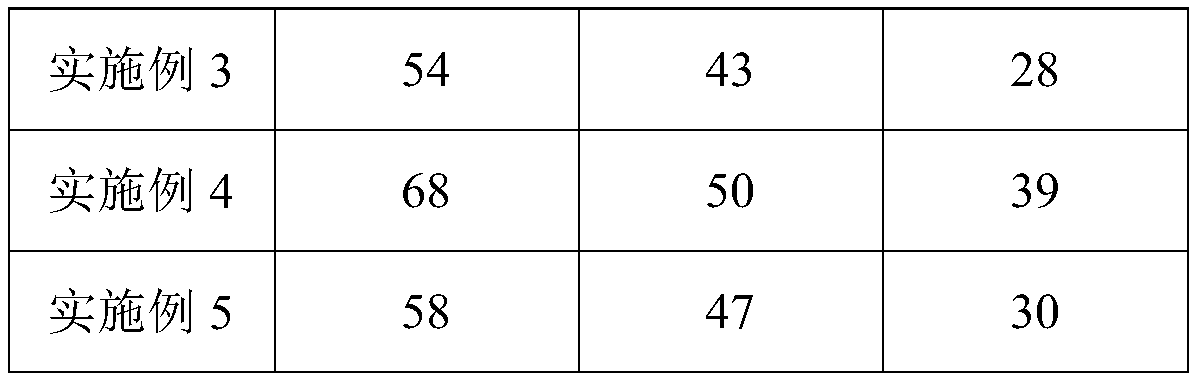

Examples

Embodiment 1

[0028] This embodiment provides a kind of polypropylene-based composite material, the preparation method of this polypropylene-based composite material comprises the following steps:

[0029] S1. Weigh 540g of polypropylene, 100g of thermoplastic polyurethane, 50g of polypropylene grafted maleic anhydride, 70g of carbon nanotubes, 210g of tetrabromobisphenol A, tetrakis[β-(3,5-di-tert-butyl-4-hydroxy Phenyl) propionic acid] pentaerythritol ester 5g, lanthanum stearate 5g, stearic acid 5g, white oil 5g, standby; Wherein, polypropylene is isotactic polypropylene; In addition, polypropylene, thermoplastic polyurethane, polypropylene grafted Toric anhydride, carbon nanotubes and tetrabromobisphenol A need to be vacuum-dried for 12 hours before weighing.

[0030] S2, the above-mentioned polypropylene, plastic polyurethane, and polypropylene grafted maleic anhydride are first placed in a banbury mixer, then add the above-mentioned other components weighed in the banbury mixer, and c...

Embodiment 2

[0034] This embodiment provides a kind of polypropylene-based composite material, the preparation method of this polypropylene-based composite material comprises the following steps:

[0035] S1. Weigh 540g of polypropylene, 120g of ethylene-vinyl acetate copolymer, 90g of polypropylene grafted glycidyl methacrylate, 60g of graphene, 170g of ammonium polyphosphate, β-(3,5-di-tert-butyl-4 -Hydroxyphenyl) octadecyl propionate 5g, lanthanum stearate 5g, zinc stearate 5g, white oil 5g, standby; Wherein, polypropylene is isotactic polypropylene and syndiotactic polypropylene mixture; In addition, Polypropylene, ethylene-vinyl acetate copolymer, polypropylene grafted with glycidyl methacrylate, graphene and ammonium polyphosphate need to be vacuum-dried for 12 hours before weighing.

[0036]S2. Put the above-mentioned polypropylene, ethylene-vinyl acetate copolymer, and polypropylene grafted glycidyl methacrylate in the internal mixer first, and then add the other components weighed...

Embodiment 3

[0040] This embodiment provides a kind of polypropylene-based composite material, the preparation method of this polypropylene-based composite material comprises the following steps:

[0041] S1. Weigh 530g of polypropylene, 140g of EPDM rubber, 70g of polypropylene grafted glycidyl methacrylate, 40g of graphene, 40g of carbon nanotubes, 160g of tricresyl phosphate, tris[2,4-ditertiary Butylphenyl] phosphite 5g, lanthanum stearate 5g, Montan wax 5g, white oil 5g, standby; Wherein, polypropylene is isotactic polypropylene, syndiotactic polypropylene and atactic polypropylene mixture; In addition, Polypropylene, EPDM rubber, polypropylene grafted with glycidyl methacrylate, graphene, carbon nanotubes, and tricresyl phosphate need to be vacuum-dried for 12 hours before weighing.

[0042] S2, first place the above-mentioned weighed polypropylene, EPDM rubber, polypropylene grafted glycidyl methacrylate in the internal mixer, and then add the above-mentioned other components weighe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com