A method for preparing pavement material and the prepared pavement material and application thereof

A technology for paving materials and powder materials, which is applied in the field of plant residue reuse and paving materials and paving materials, can solve the problems of complex chemical composition of emulsified asphalt, limited use in ecological fields, and impact on the appearance of pavement, and achieve social efficiency. And the effect of remarkable economic benefit, low cost and good road comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

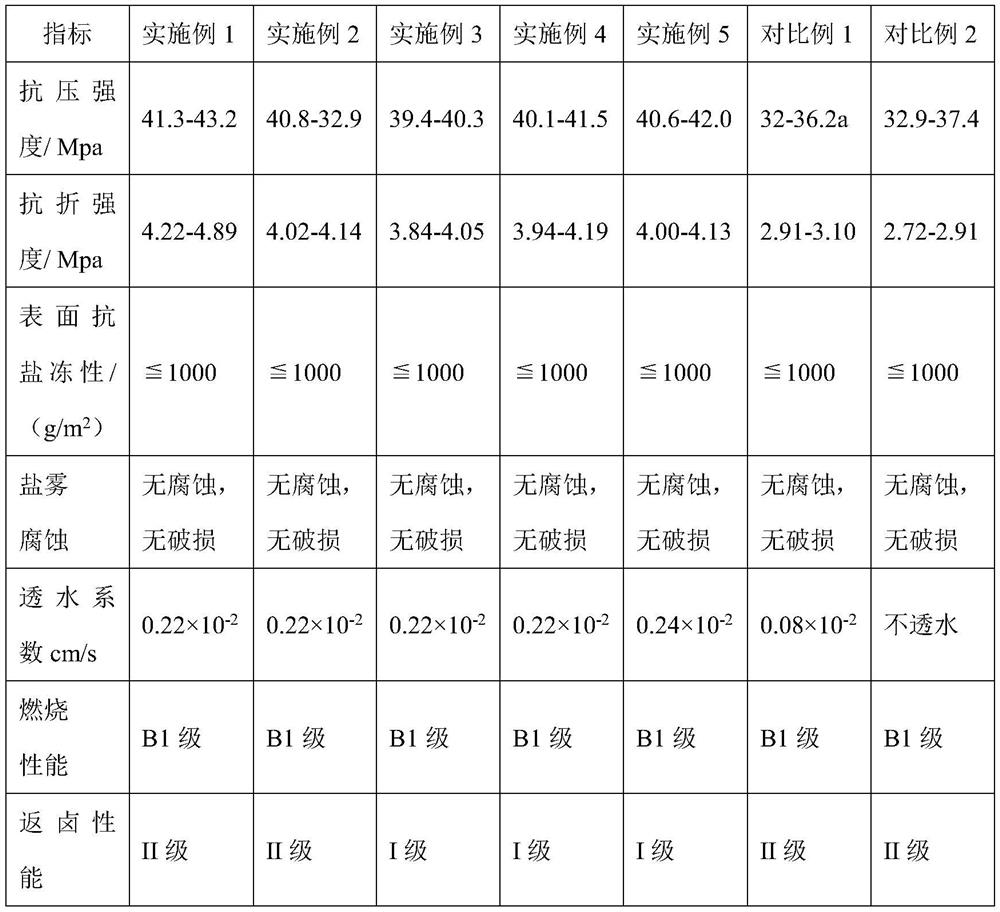

Examples

Embodiment 1

[0059] The preparation of embodiment 1 pavement material

[0060] 1. Ratio preparation

[0061] 1.1 Collection and treatment of plant residues

[0062] Collect plant residues in the area to be treated, such as discarded branches after landscaping, remove rotten grass, leaves, branches, etc., and use conventional mechanical crushing methods to crush the plant residues to obtain a certain length and thickness. of plant debris.

[0063] Among them, the selection of plant residues and the length and thickness of plant fragments can be adjusted according to different construction purposes. For example, in order to obtain a paving material with a certain strength, it is necessary to choose undecomposed lignified branches as the source of paving materials; if it is only used as a slope cover with low hardness requirements, non-lignified branches and leaves such as reeds and straws can be selected . Since the length and thickness of the plant debris also have a significant impact ...

Embodiment 2

[0090] The preparation of embodiment 2 paving materials

[0091] Except that when the dried plant fragments are mixed with the powder, the powder is added several times and then water is added, the others are the same as in Example 1.

Embodiment 3

[0092] The preparation of embodiment 3 paving materials

[0093] Except that fly ash is also included in the powder, others are the same as embodiment 1 or implementation 2.

[0094] Wherein, the consumption of fly ash is 15% of magnesium oxide weight.

[0095] It should be noted that the technical purpose of the present invention can be achieved if the amount of fly ash is any value within the range of 5-20% by weight of magnesium oxide.

[0096] After a large number of experiments, the present invention finds that after replacing part of magnesium oxide with fly ash, under the condition that its bonding and curing properties are not affected, not only the reuse of industrial waste can be realized, but also the cost of material preparation can be greatly reduced. Its compressive strength is not affected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com