Recovery device and cyclic utilization method for waste acid water in metribuzin production

A recovery device and waste acid water technology, applied in chemical instruments and methods, water aeration, water pollutants, etc., can solve the problems of low added value sulfate, alkali consumption, energy waste, etc., to achieve great practicality and economy High performance, low energy consumption, and simple processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

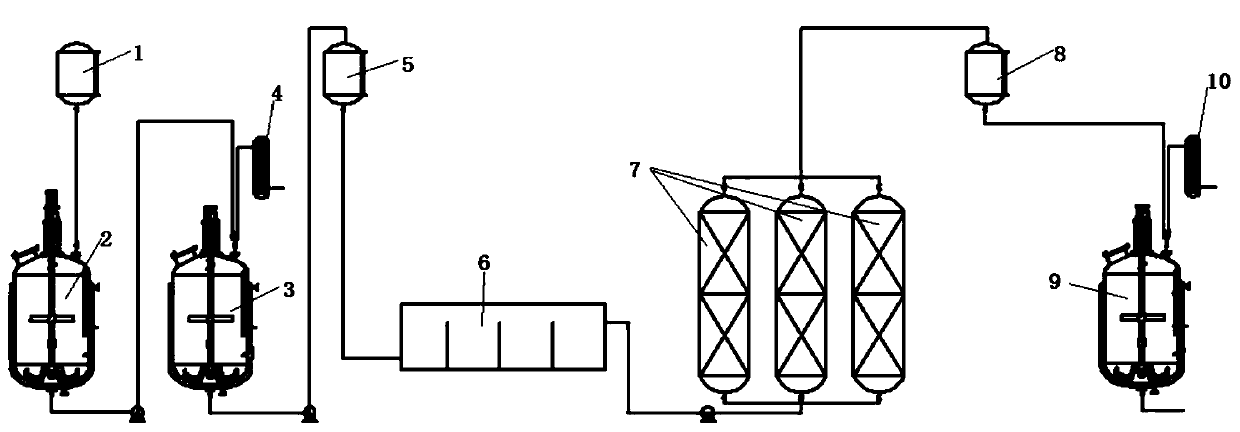

Method used

Image

Examples

Embodiment 1

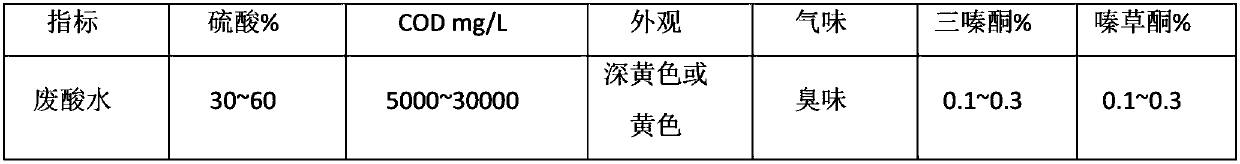

[0054] The specific indicators of the waste acid water produced by the mecitrione process are as follows:

[0055] index sulfuric acid% COD mg / L Exterior odor Triazinone% Metrizone % waste acid water 43 12080 yellow the smell 0.21 0.18

[0056]Add 8 t of the above waste acid water to 2 t of toluene, heat up to 60-70°C, heat and stir for 1 h, then let it stand for 0.5 h, separate layers, and the lower layer of acid water enters the aeration tank 3. The toluene phase is concentrated and put into the methylation reaction section. The temperature of the aeration tank 3 is 80-90°C, the rate of compressed air is 5 cubic meters per minute, and the aeration time is 2 hours. After cooling down to 40-50°C, it enters the sedimentation tank. The flow rate of the settling tank is 0.1m / s, the settling time is 30min, and the settled solids are treated as sludge. After settling, the acid water COD value is 6810mg / L. The acid water enters the resin towe...

Embodiment 2

[0058] The specific indicators of the waste acid water produced by the mecitrione process are as follows:

[0059] index sulfuric acid% COD mg / L Exterior odor Triazinone% Metrizone % waste acid water 50 10800 dark yellow the smell 0.15 0.10

[0060] Add 8 t of the above waste acid water to 2 t of toluene, heat up to 60-70°C, heat and stir for 1 h, then let it stand for 0.5 h, separate layers, and the lower layer of acid water enters the aeration tank 3. The toluene phase is concentrated and put into the methylation reaction section. The temperature of the aeration tank 3 is 60-70°C, the rate of compressed air is 6 cubic meters per minute, and the aeration time is 2 hours. After cooling down to 40-50°C, it enters the sedimentation tank. The flow rate of the settling tank is 0.1m / s, the settling time is 30min, and the settled solids are treated as sludge. After settling, the acid water COD value is 5110mg / L. The acid water enters the resi...

Embodiment 3

[0062] The specific indicators of the waste acid water produced by the mecitrione process are as follows:

[0063] index sulfuric acid% COD mg / L Exterior odor Triazinone% Metrizone % waste acid water 40 23000 dark yellow the smell 0.25 0.21

[0064] Add 8 t of the above waste acid water to 2 t of toluene, heat up to 60-70°C, heat and stir for 1 h, then let it stand for 0.5 h, separate layers, and the lower layer of acid water enters the aeration tank 3. The toluene phase is concentrated and put into the methylation reaction section. The temperature of the aeration kettle 3 is 60-70°C, the rate of compressed air is 2 cubic meters per minute, and the aeration time is 5 hours. After cooling down to 40-50°C, it enters the sedimentation tank. The flow rate of the settling tank is 0.1m / s, the settling time is 30min, and the settled solids are treated as sludge. After settling, the COD value of the acid water is 6130mg / L. It enters the resin t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com