Dehydrogenation catalyst for preparing styrene, preparation method and application

A dehydrogenation catalyst and catalyst technology, applied in the direction of catalysts, carbon compound catalysts, chemical instruments and methods, etc., can solve the problems of high by-product toluene and low selectivity of low-potassium catalysts, and achieve less by-product toluene and selectivity of styrene sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] would be equivalent to 55.95 parts Fe 2 o 3 Iron oxide red, equivalent to 15.67 parts Fe 2 o 3 Iron oxide yellow, equivalent to 9.38 parts K 2 Potassium carbonate of O, equivalent to 8.76 parts CeO 2 of cerium acetate, equivalent to 2.76 parts of MoO 3 ammonium molybdate, calcium hydroxide equivalent to 3.3 parts of CaO, 2.86 parts of GeO 2 , 1.32 Ta 2 o 5Stir in a kneader with 5.2 parts of graphite for 2 hours, add deionized water accounting for 22.3% of the total weight of the catalyst raw material, stir for 0.8 hours, take out the extruded strips, extrude them into particles with a diameter of 3 mm and a length of 6 mm, and put them into an oven. ℃ for 2.5 hours, 130 ℃ for 3.0 hours, then placed in a muffle furnace, calcined at 550 ℃ for 3 hours, and 740 ℃ for 3 hours to obtain the finished catalyst. The composition of the catalyst is listed in Table 1.

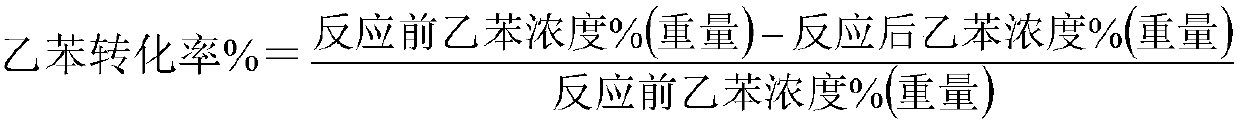

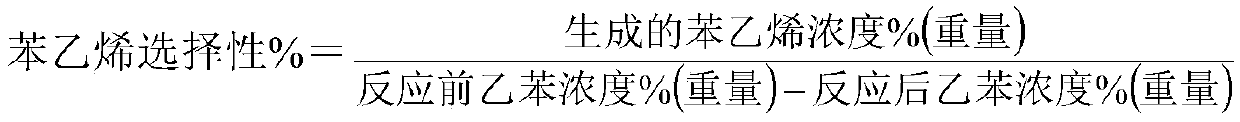

[0040] 100 milliliters of catalysts are loaded into the reactor, and the reaction time is 1.2 hours at no...

Embodiment 2

[0048] Except for Nb 2 o 5 Replace Ta 2 o 5 Outside, catalyst preparation method and catalyst evaluation condition are with embodiment 1, specifically:

[0049] would be equivalent to 55.95 parts Fe 2 o 3 Iron oxide red, equivalent to 15.67 parts Fe 2 o 3 Iron oxide yellow, equivalent to 9.38 parts K 2 Potassium carbonate of O, equivalent to 8.76 parts CeO 2 of cerium acetate, equivalent to 2.76 parts of MoO 3 ammonium molybdate, calcium hydroxide equivalent to 3.3 parts of CaO, 2.86 parts of GeO 2 , 1.32 Nb 2 o 5 Stir in a kneader with 5.2 parts of graphite for 2 hours, add deionized water accounting for 22.3% of the total weight of the catalyst raw material, stir for 0.8 hours, take out the extruded strips, extrude them into particles with a diameter of 3 mm and a length of 6 mm, and put them into an oven. ℃ for 2.5 hours, 130 ℃ for 3.0 hours, then placed in a muffle furnace, calcined at 550 ℃ for 3 hours, and 740 ℃ for 3 hours to obtain the finished catalyst. Th...

Embodiment 3

[0051] In addition to using V 2 o 5 Replace Ta 2 o 5 Outside, catalyst preparation method and catalyst evaluation condition are with embodiment 1, specifically:

[0052] would be equivalent to 55.95 parts Fe 2 o 3 Iron oxide red, equivalent to 15.67 parts Fe 2 o 3 Iron oxide yellow, equivalent to 9.38 parts K 2 Potassium carbonate of O, equivalent to 8.76 parts CeO 2 of cerium acetate, equivalent to 2.76 parts of MoO 3 ammonium molybdate, calcium hydroxide equivalent to 3.3 parts of CaO, 2.86 parts of GeO 2 , 1.32 copies of V 2 o 5 Stir in a kneader with 5.2 parts of graphite for 2 hours, add deionized water accounting for 22.3% of the total weight of the catalyst raw material, stir for 0.8 hours, take out the extruded strips, extrude them into particles with a diameter of 3 mm and a length of 6 mm, and put them into an oven. ℃ for 2.5 hours, 130 ℃ for 3.0 hours, then placed in a muffle furnace, calcined at 550 ℃ for 3 hours, and 740 ℃ for 3 hours to obtain the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com