Novel zirconium nano hybrid material and application method

A nano-hybrid material and zirconium-based technology, applied in chemical instruments and methods, separation methods, and other chemical processes, can solve the problem of low phosphorus removal efficiency and achieve good removal capacity and high loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is a preparation process of a novel zirconium-based nano-hybrid material, including the following steps:

[0046] 1) Weigh 70g of ZrOCl in a 500mL beaker 2 ·8H 2 0, and pour 100mL of water, concentrated hydrochloric acid, and absolute ethanol solution with a volume ratio of 1:1:2 to obtain a mixed solution;

[0047] 2) Weigh 30g of 201×4 resin, which was purchased from Nankai University Chemical Factory, add the resin to the above mixed solution (dosing concentration 300g / L), soak for 12h, and then put the resin at 50°C and 20rpm Heat and stir for 12 hours until the solution is not completely dry, then transfer to a watch glass to dry naturally, use a medicine spoon to crush the zirconium powder on the surface of the material, and use a 0.6mm sieve to remove the zirconium powder;

[0048] 3) Add the material obtained in step 2) into 200 mL of NaOH solution with a mass fraction of 5%, and stir at 300 rpm for 12 h. Filter out the material and wash with ...

Embodiment 2

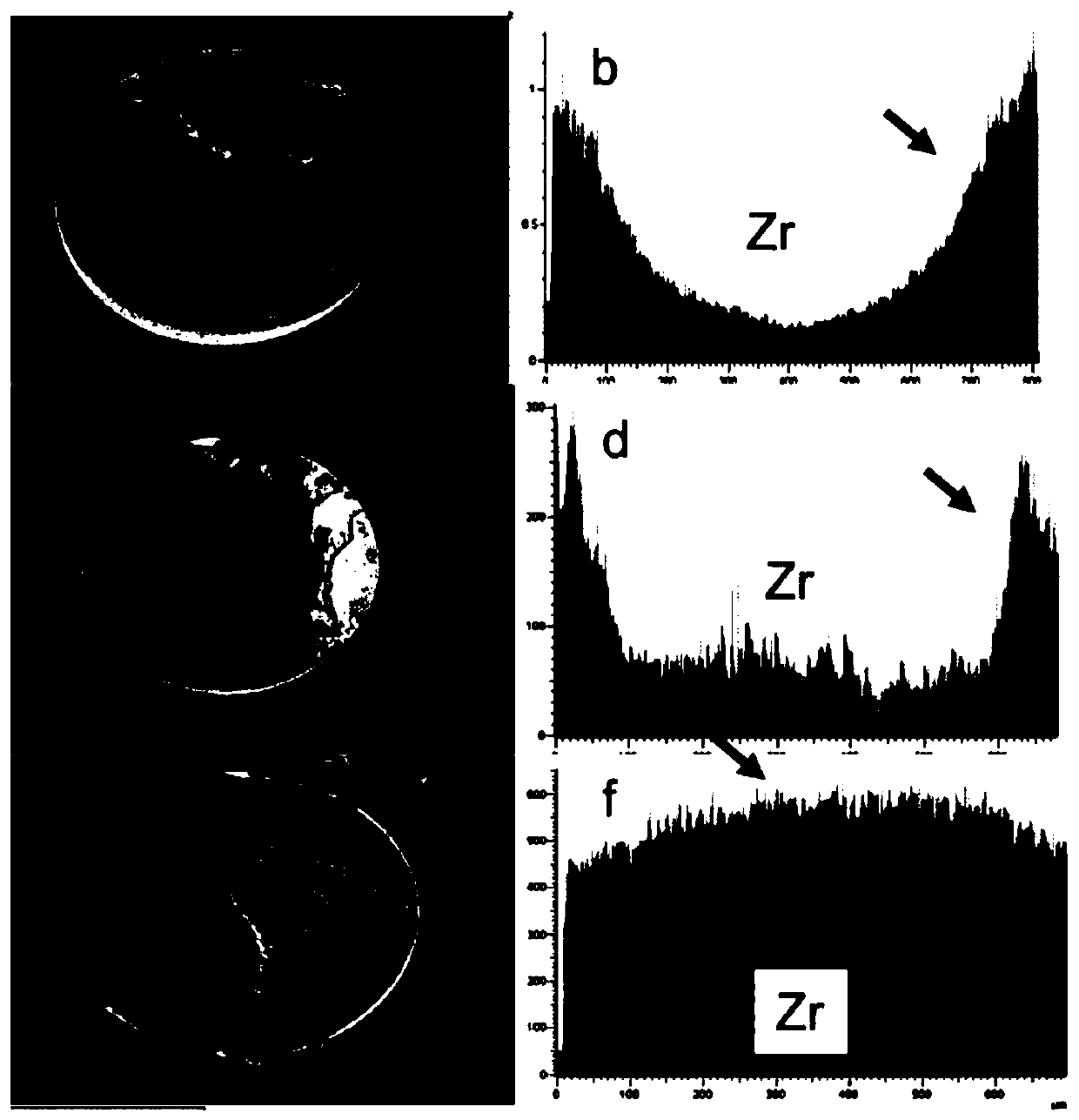

[0055] 1) Using SEM-EDS to characterize the internal morphology and zirconium content of the material, the three materials are referred to as HZO-201×4 (Example 1), HZO-201 (Comparative Example 1) and HZONDA88 (Comparative Example 2), Specific results such as figure 1 shown. Among them, Figure a and Figure b are the cross-section morphology and Zr line scan diagram of the HZO-201 material obtained in Comparative Example 1; Figure c and Figure d are the cross-section morphology and Zr line scan diagram of the HZONDA88 material obtained in Comparative Example 2; Figure e and Figure f are the cross-section morphology and Zr line scan diagram of the material HZO-201×4 obtained in Example 1, respectively;

[0056] The results show that the zirconium distribution law of HZO-201 and HZONDA88 is more on both sides and less in the middle, and more HZO particles are loaded on the outer spherical layer; while the distribution of HZO inside HZO-201×4 is more uniform.

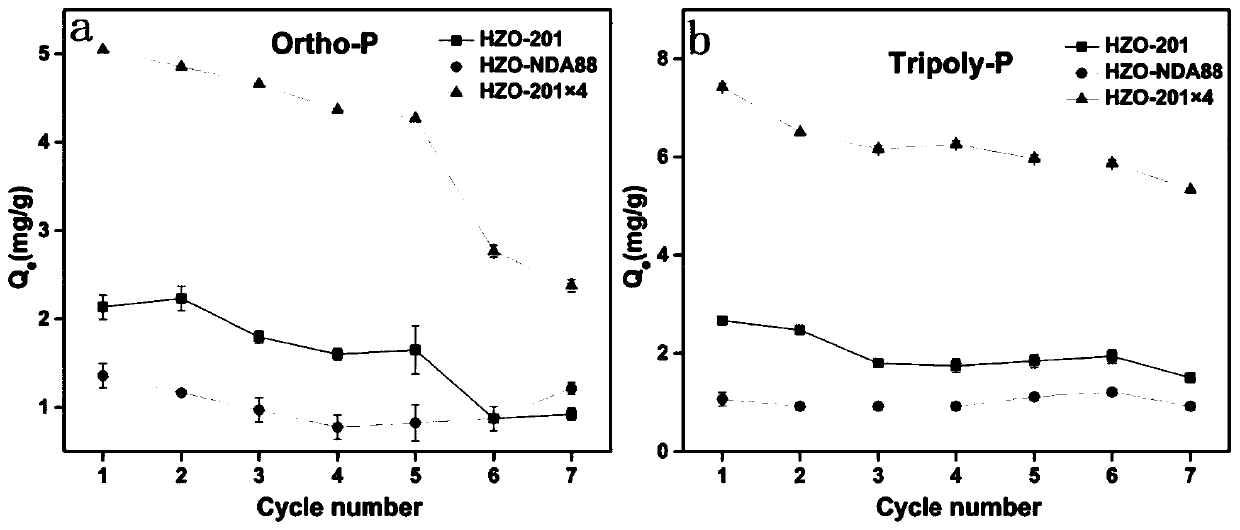

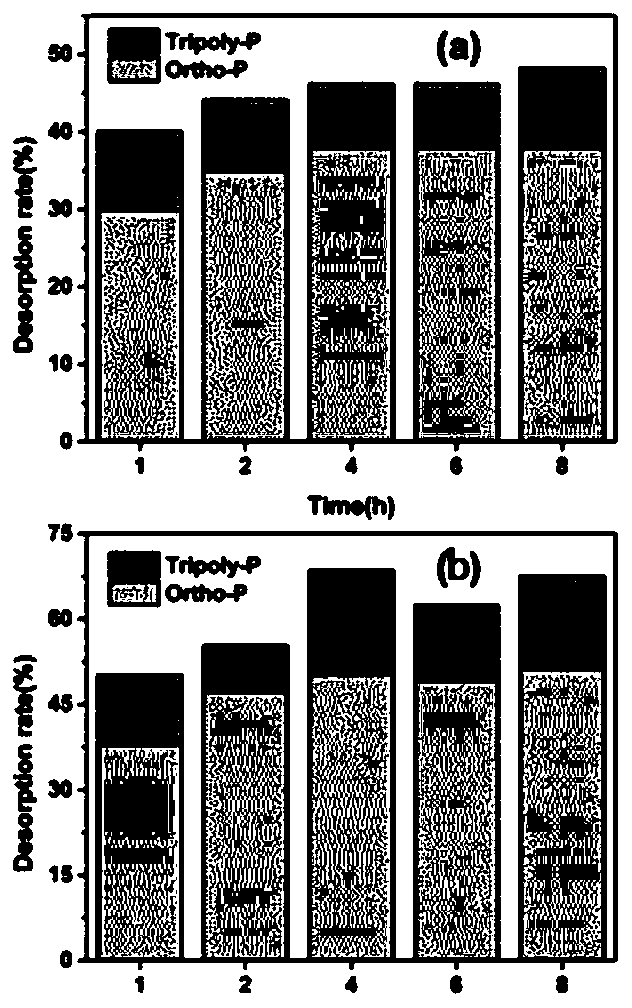

[0057] Second, co...

Embodiment 3

[0063] This embodiment is a preparation process of a novel zirconium-based nano-hybrid material, including the following steps:

[0064] 1) Weigh 100g of ZrOCl in a 500mL beaker 2 ·8H 2 0, and pour 100mL of water, concentrated hydrochloric acid, and absolute ethanol solution with a volume ratio of 1:1:2 to obtain a mixed solution;

[0065] 2) Weigh 5g of 201×4 resin, add it to the above mixed solution (dosing concentration 50g / L), soak for 24 hours, heat and stir at 40°C and 18rpm for 10 hours until the solution is not completely dry, and then transfer to The watch glass is air-dried naturally, and the zirconium powder on the surface of the material is crushed with a medicine spoon, and the zirconium powder is sieved with a 0.6mm sieve;

[0066] 3) Add the material obtained in step 2) into 200 mL of NaOH solution with a mass fraction of 15%, and stir at 300 rpm for 12 h. Filter out the material and wash with water until the effluent is neutral.

[0067] 4) Add the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com