Carbon plate carbon loading system and method

A carbon plate and carbon particle technology, applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems affecting the sealing quality of the consistent carbon plate appearance quality, lack of filling, vibration, dust discharge system, etc. The problem of uneven particle size distribution of activated carbon particles can achieve the effect of reducing labor complexity, labor intensity and filling difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

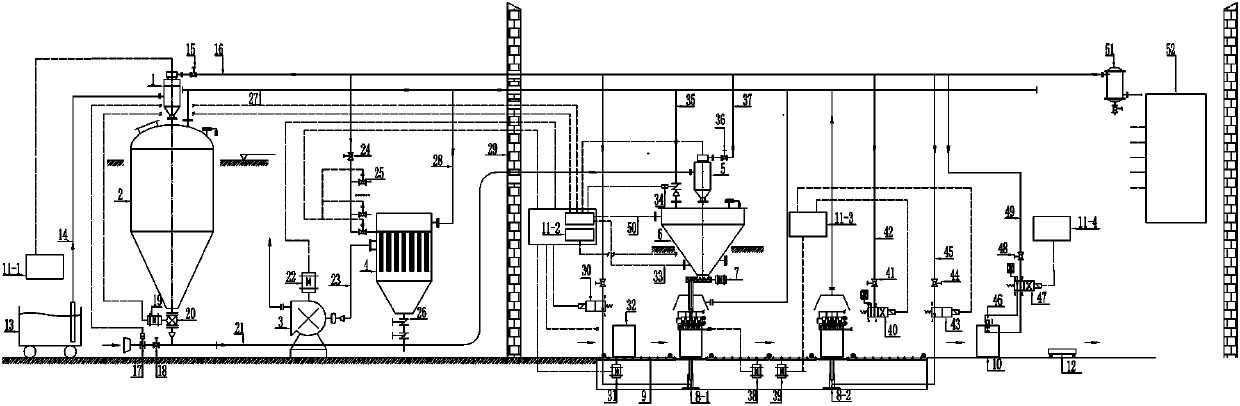

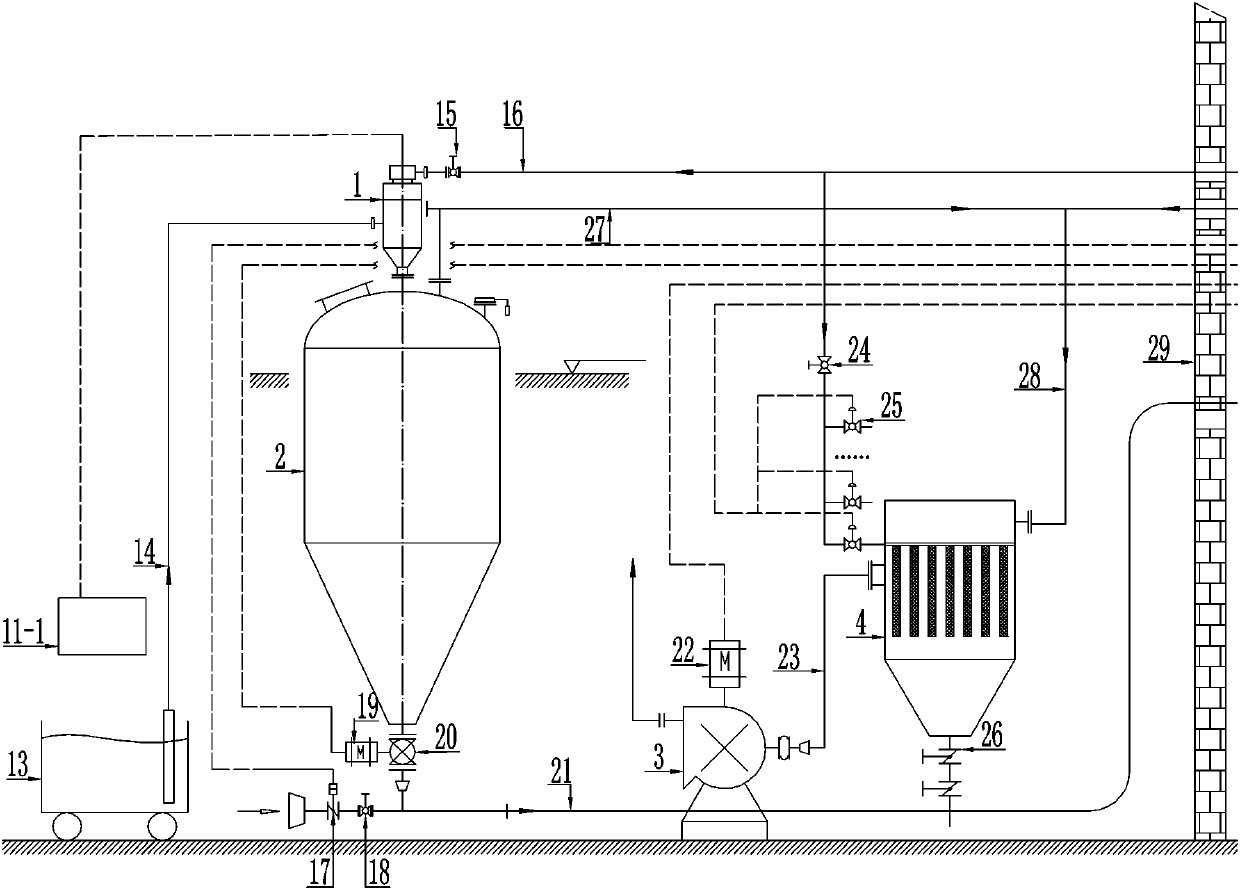

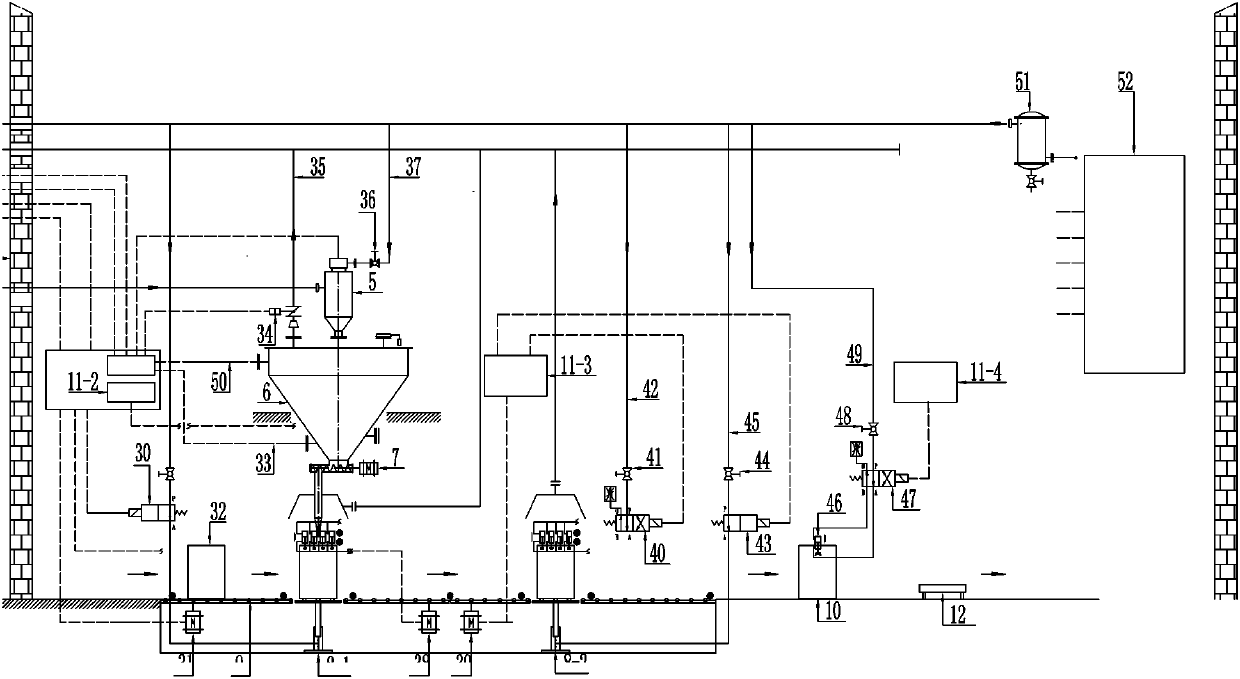

[0038] like Figure 1-3As shown, the charcoal plate charging system includes a raw material storage tank 2, the feed port of the raw material storage tank 2 is connected with the first vacuum feeder 1 and realizes feeding, and the discharge port of the raw material storage tank 2 Connect to the second vacuum feeder 5 through the powder conveying pipe 21, the second vacuum feeder 5 is arranged on the top of the feeding tank 6, and the discharge port of the feeding tank 6 is equipped with a feeder 7 , the discharge port of the feeder 7 is connected to the first vibrating table 8-1 directly below it through a pipeline and realizes vibrating charging, and the front and rear ends of the first vibrating table 8-1 are respectively provided with The roller conveyor 9 of the plate mold, the second vibrating table 8-2 is arranged on the subsequent conveying line of the first vibrating table 8-1, and the subsequent conveying line of the second vibrating table 8-2 is provided with a The ...

Embodiment 2

[0053] The method for charging carbon in the carbon plate charging system:

[0054] Step1: The suction pipe 14 of the first vacuum feeder 1 fills the raw material into the raw material storage tank 2;

[0055] Step2: Start the dust collector 4, and the carbon particles discharged from the dust outlet of the raw material storage tank 2 enter the dust collector 4 through the dust collection main pipe 27, and the dust is discharged outside the system under the joint action of the dust collector 4 and the fan 3;

[0056] Step3: The remaining available carbon particles are filled into the feeding tank 6 through the powder conveying pipe 21 under the action of the first vacuum feeder 1;

[0057] Step4: Through the joint action of the feeder 7 and the vibrating table 8-1, the carbon particles are evenly filled into the carbon plate;

[0058] Step5: The carbon plate is sent to the vibrating table 8-2 by the roller conveyor 9 for secondary vibration so that the carbon particles inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com