Medical anatomy instrument disinfection equipment

A technology for dissection instruments and disinfection equipment, which is applied in the field of medical anatomy, and can solve the problems that the disinfectant cannot be soaked, waste liquid cannot be processed, and clamping is inconvenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

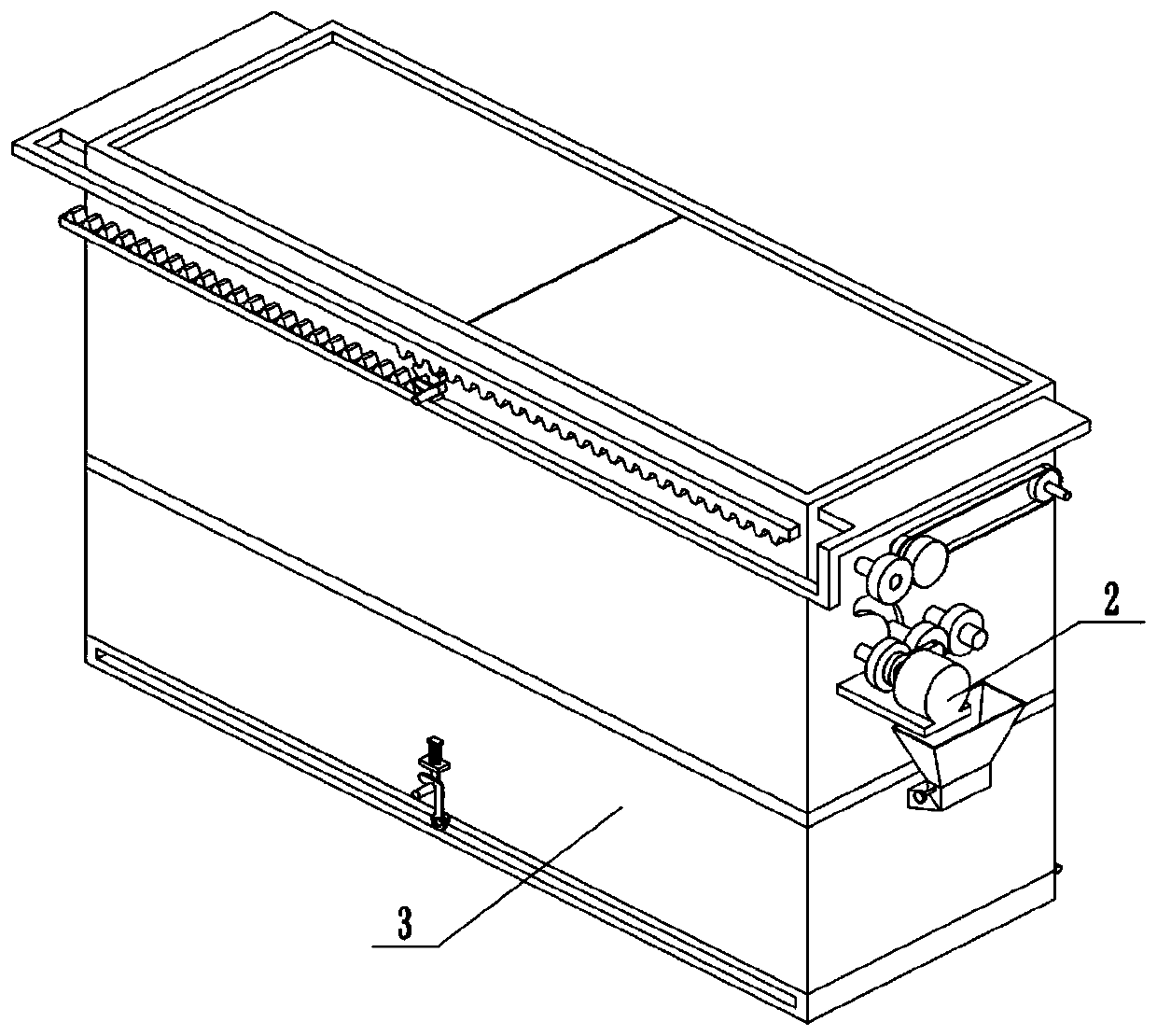

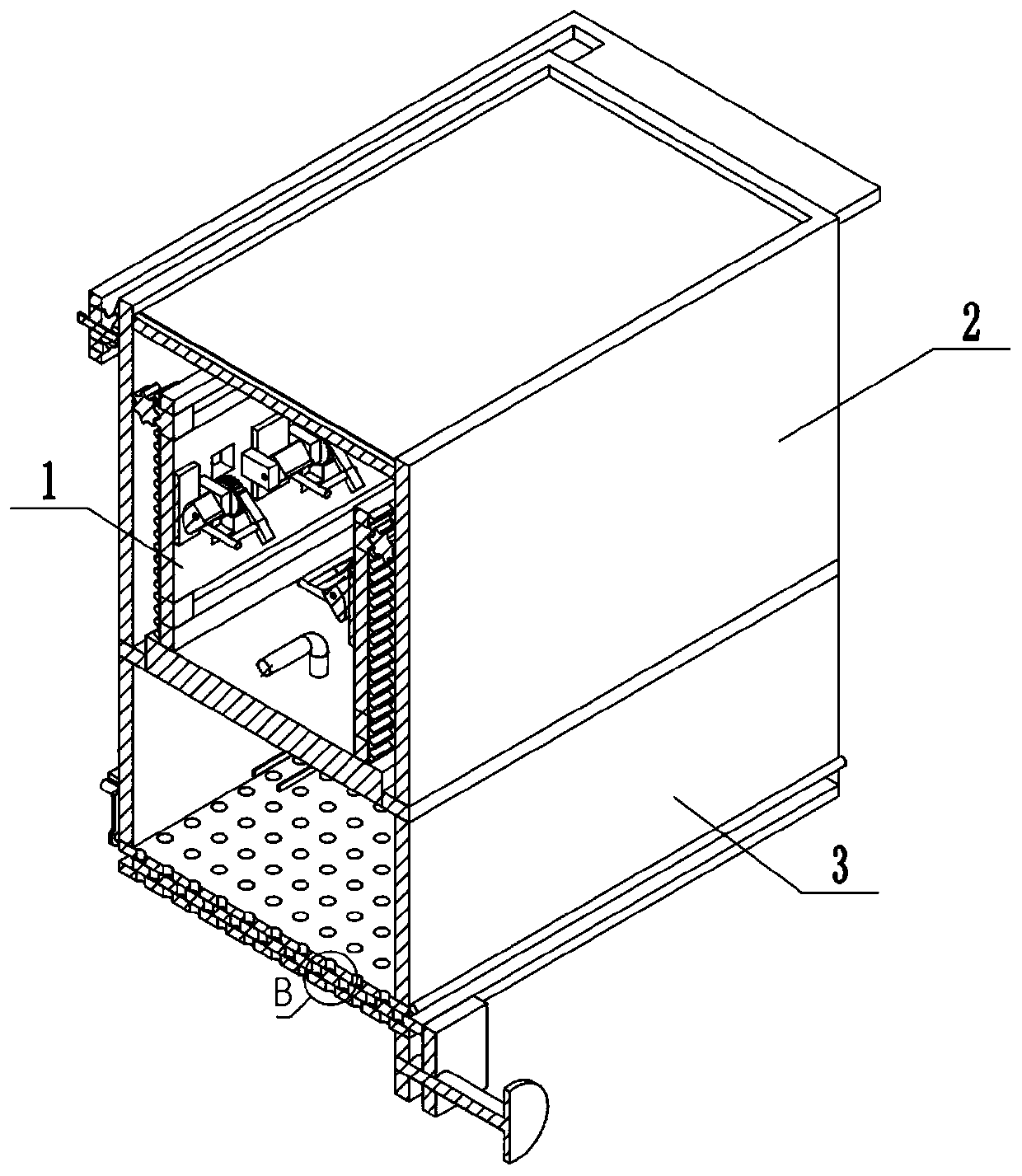

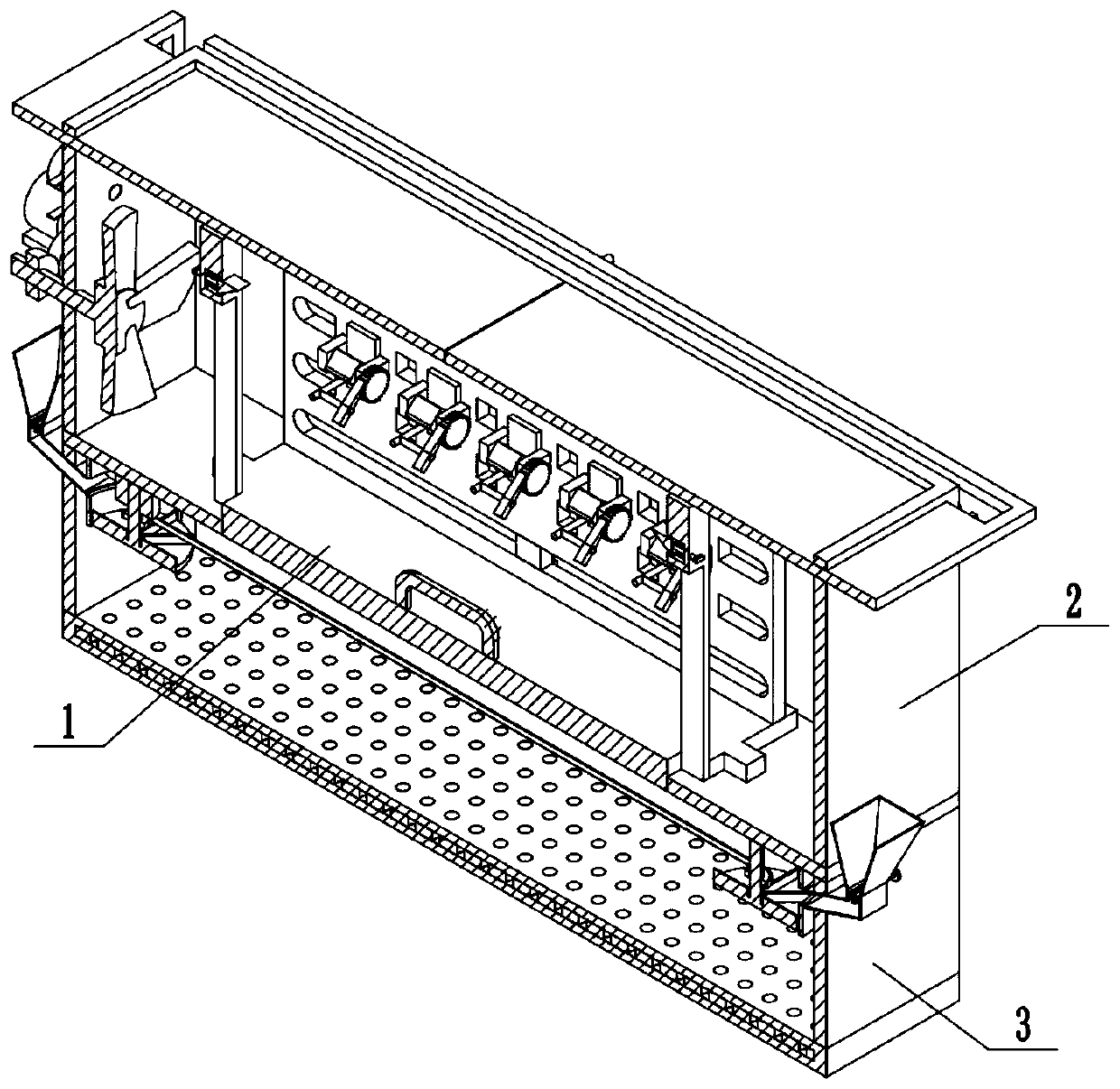

[0034] Combine below Figure 1-20 In this embodiment, a medical dissection instrument disinfection equipment includes a clamping assembly 1, a flushing and disinfection assembly 2, and a purification assembly 3. The clamping assembly 1 is connected to the washing and disinfection assembly 2, and the purification assembly 3 is connected with clamping assembly 1

specific Embodiment approach 2

[0036] Combine below Figure 1-20 In this embodiment, this embodiment will further describe Embodiment 1. The clamping assembly 1 includes an operating rod 1-1, a pawl shaft 1-2, a pawl 1-3, a pawl rubber pad 1-4, Ratchet 1-5, eccentric clamping wheel 1-6, clamping wheel shaft 1-7, clamping lug 1-8, clamping rubber pad 1-9, support plate 1-10, lifting bottom plate 1-11, drain Bottom plate 1-12, lifting slide rail 1-13, limiting inclined block 1-14, inclined block chute 1-15, square spring 1-16, pull rod 1-17, rack 1-18, lifting bottom plate limiting block 1-19 and handle 1-20, the operating rod 1-1 is connected with the pawl shaft 1-2, the pawl shaft 1-2 is rotationally connected with the pawl 1-3, and the pawl 1-3 is connected with the pawl rubber pad 1 -4 is connected, the ratchet 1-5 is connected with the clamping lug 1-8, the eccentric clamping wheel 1-6 is connected with the operating rod 1-1, the eccentric clamping wheel 1-6 is connected with the clamping wheel shaft 1-...

specific Embodiment approach 3

[0038] Combine below Figure 1-20 In this embodiment, the embodiment 1 is further described in this embodiment. The flushing and disinfection assembly 2 includes sliding door I 2-1, sliding door II 2-2, disinfection chamber 2-3, upper rack 2-4, lower rack Bar 2-5, door opening gear 2-6, door opening gear shaft 2-7, door opening rocker 2-8, motor I 2-9, motor I bracket 2-10, motor I shaft 2-11, friction block 2-12, Arm 2-13, gear I 2-14, arm shaft 2-15, arm shaft chute 2-16, gear II 2-17, gear III 2-18, gear III shaft 2-19, fan blade 2-20, Gear Ⅳ2-21, gear Ⅳ shaft 2-22, sprocket Ⅰ2-23, chain Ⅰ2-24, sprocket Ⅱ2-25, sprocket Ⅱ shaft 2-26, lifting gear Ⅰ2-27, gear Ⅴ2-28, gear Ⅴ Shaft 2-29, sprocket III 2-30, chain II 2-31, sprocket IV 2-32, sprocket IV shaft 2-33 and lifting gear II 2-34, sliding door I 2-1, sliding door II 2-2 are all compatible with disinfection Chamber 2-3 is slidingly connected, disinfection chamber 2-3 is connected with drain bottom plate 1-12, sliding door...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com