Fungus cleaning equipment used for fungus milk processing

A technology for cleaning equipment and fungi, applied in the field of bacteria cleaning equipment for bacteria milk processing, can solve the problems of insufficient cleaning of bacteria, affecting the quality of bacteria milk, bland taste, etc., so as to reduce the generation of cleaning dead ends and improve the overall quality. , the effect of thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

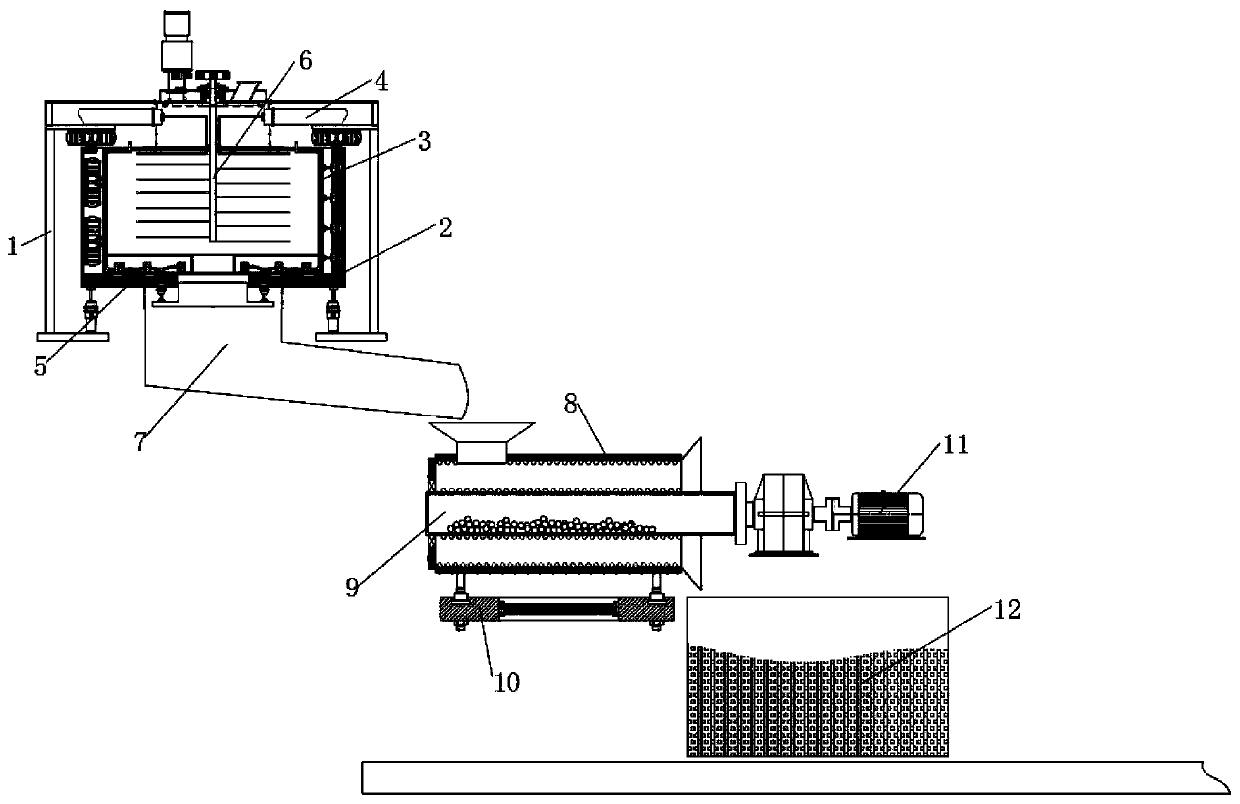

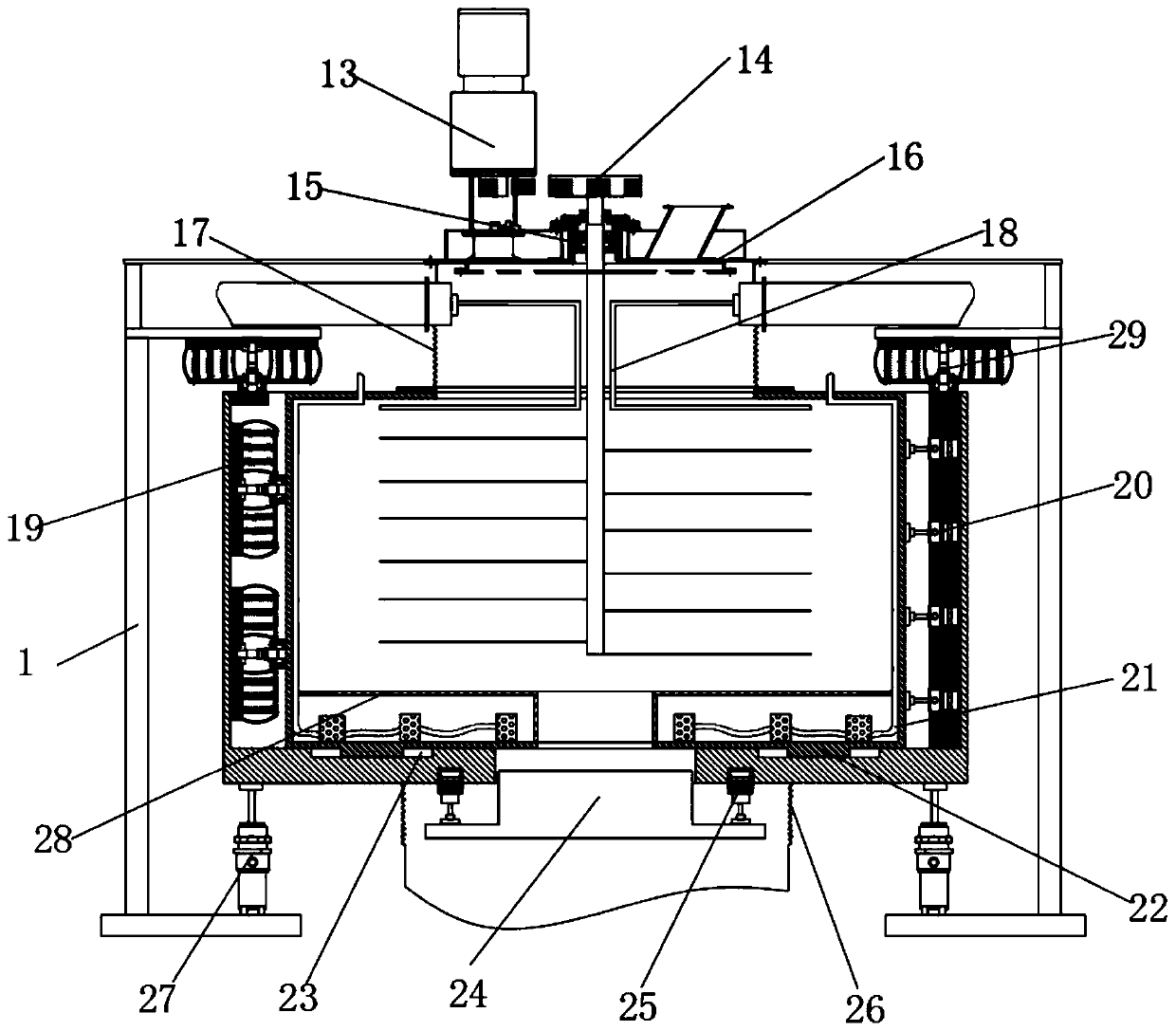

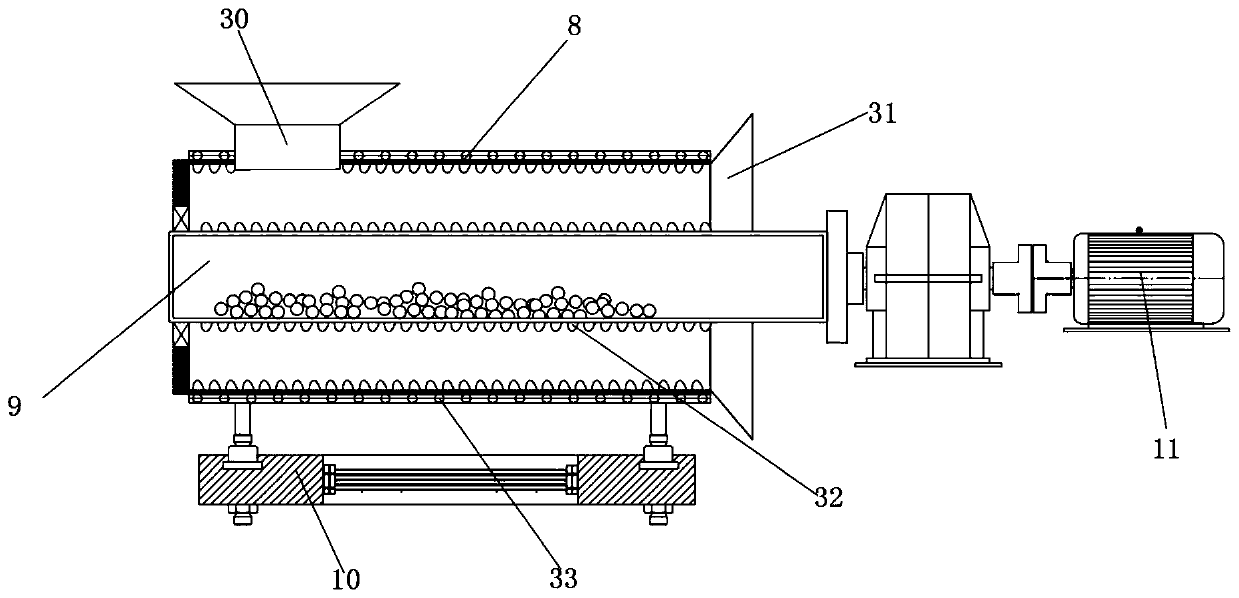

[0023] Example: see Figure 1-4 , the present invention provides a technical solution: a fungus cleaning equipment for bacterial milk processing, which includes a frame 1, a vertical oscillating component, a horizontal oscillating component, a stirring component, a cleaning component, a sewage discharge component and a primary crushing and drying component , wherein the vertical oscillating assembly is arranged on the frame 1 for vertically oscillating the outer casing 2, the horizontal oscillating assembly is arranged in the outer casing 2 for horizontally oscillating the inner casing 3, and the output of the stirring assembly The end extends into the inner shell seat 3 to cooperate with the cleaning component and the sewage discharge component to realize the cleaning of the fungus, and the cleaned fungus enters the collection bin 12 after being processed by the primary crushing and drying component.

[0024] Wherein, the vertical oscillating assembly includes two buffer memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com