Full-automatic complete punching equipment for waste lead-acid storage batteries

A lead-acid battery, fully automatic technology, applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of low automation, acid corrosion of human body, waste of resources, etc., to achieve high automation and better working environment Excellent, resource-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The embodiments of the present invention will be further described below in conjunction with the drawings.

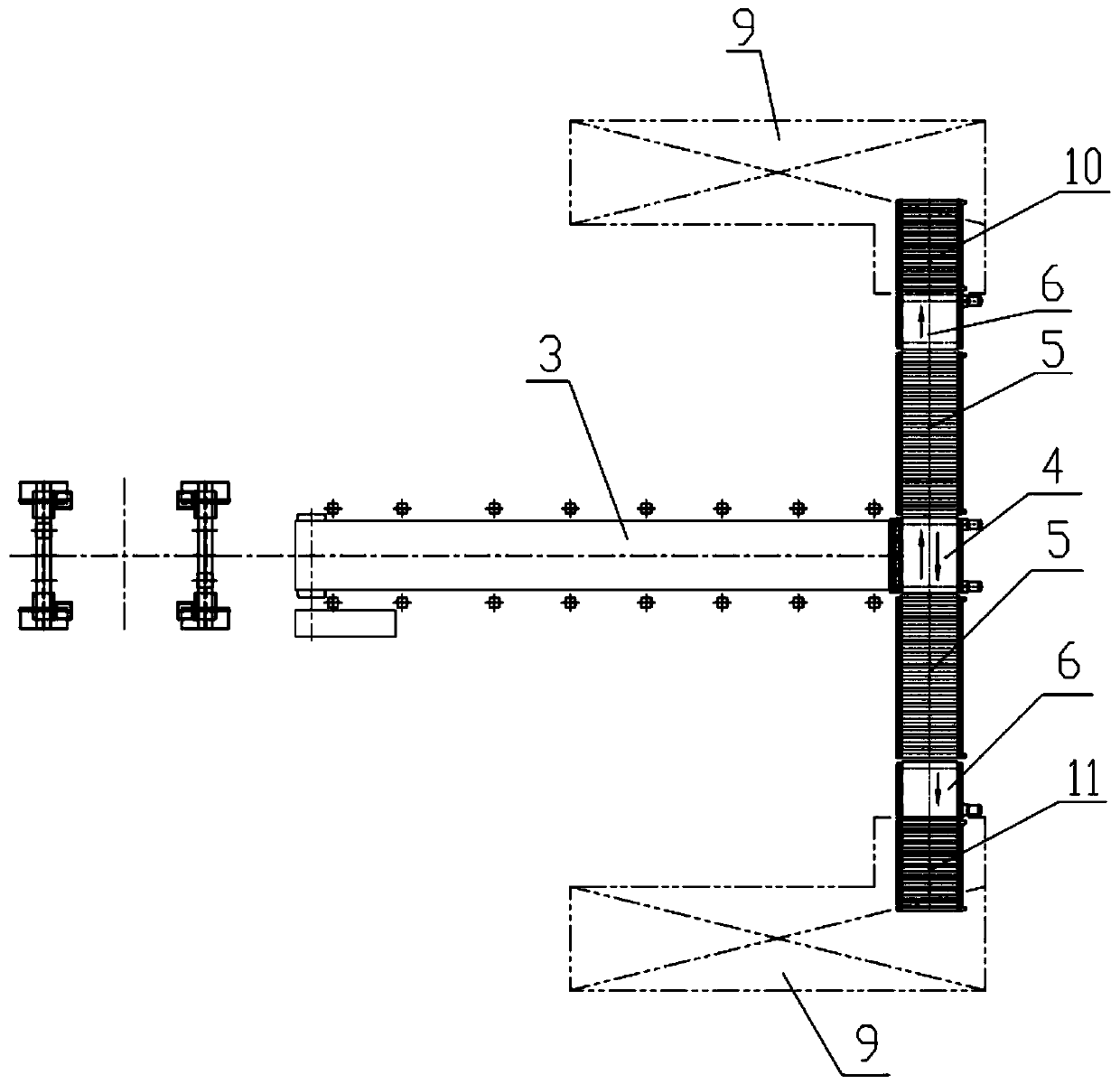

[0026] A complete set of fully automatic drilling equipment for waste lead-acid batteries, including a feeding device 1, a metal removal device 2, a conveying device 3, a two-way drive device 4, a transfer device 5, a one-way drive device 6, an automatic unloading device 7 and a punching device. 孔装置8。 Hole device 8.

[0027] The feeding device 1 is located at the head end of the conveying device 3. In this embodiment, the conveying device 3 uses a belt conveyor (belt conveyors are in the prior art and will not be described in detail here), and the feeding device 1 uses vibration The motor-driven hopper transports waste lead-acid batteries from the feeding device 1 to the head end of the conveying device 3. The metal removing device 2 is located above the conveying device 3. When the used lead-acid battery is transported from the head end of the conveying device 3 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com