Method for adjusting well group after lot of oil-displacing fluid is injected into thin oil reservoir water injection well of sandstone reservoir

A technology for thin and poor oil layers and sandstone oil reservoirs, which is applied in the field of adjustment of well groups after injecting large-dose flooding fluid into water injection wells in thin and poor oil layers of sandstone oil reservoirs, so as to ensure well opening time rate, improve oil production speed and recovery degree, Guaranteed effect of injection and extraction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

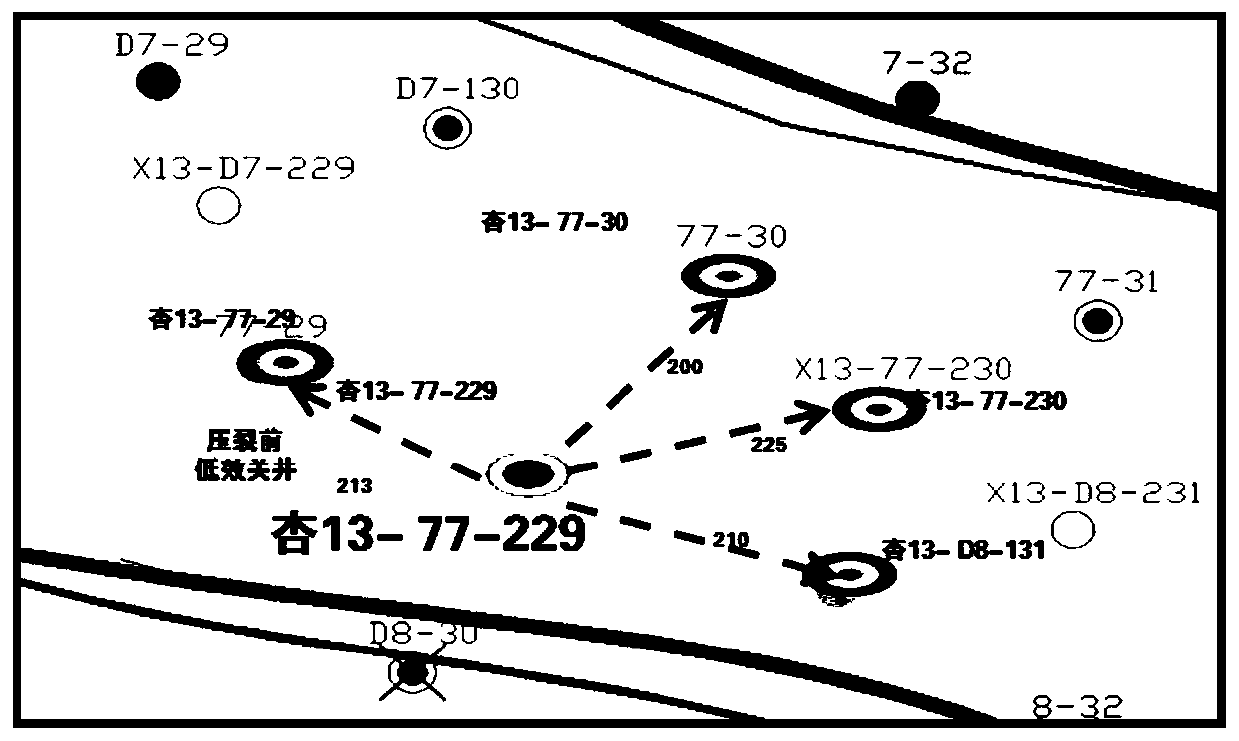

[0022] In conjunction with Daqing Oilfield Xingshugang Oilfield Xing 13-77-229 well the present invention is further described:

[0023] The water injection well Xing13-77-229 is connected with four production wells Xing13-77-29, Xing13-Ding8-131, Xing13-77-230 and Xing13-77-30. After the water injection well Xing 13-77-229 injected a large amount of displacement fluid, the entire well group was adjusted in combination with the production status of its connected wells and its own water absorption capacity. The specific adjustment method includes the following steps:

[0024] (1), Well Xing 13-77-229 and the connected oil well group and its surrounding wells are distributed as follows figure 2 As shown, the monitoring of the water injection profile after injecting a large amount of oil displacement fluid in Well Xing 13-77-229 should be carried out regularly, and the monitoring of the production profile of connected oil wells around Well Xing 13-77-229 should be carried out r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com